A kind of moisture-absorbing and warm-keeping mask and preparation method thereof

A warm-keeping, mask technology, applied in chemical instruments and methods, melt spinning, protective equipment, etc., can solve the problems of poor man-machine relationship and poor thermal insulation of masks for users who wear glasses in winter, and achieve good comfort and fiber opening effect. Good, difficulty reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

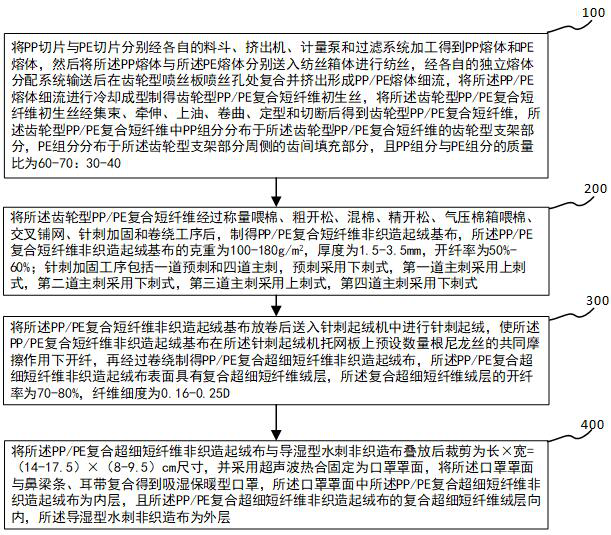

[0032] figure 1 It is a method flow chart of a method for preparing a moisture-absorbing and warm-keeping mask according to an exemplary embodiment, such as figure 1 Shown, the preparation method of described moisture-absorbing warm type mouth mask comprises:

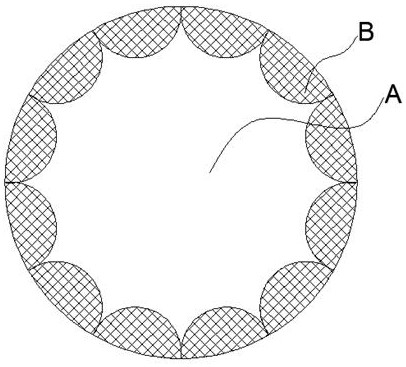

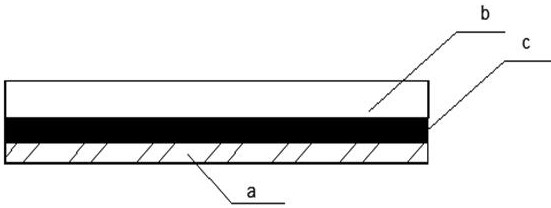

[0033] Step 100: Processing PP slices and PE slices through their respective hoppers, extruders, metering pumps, and filtration systems to obtain PP melts and PE melts, and then feeding the PP melts and the PE melts into the The spinning box is used for spinning, and after being conveyed by their own independent melt distribution system, they are compounded and extruded at the spinneret hole of the gear-shaped spinneret to form a fine stream of PP / PE melt, and the fine stream of the PP / PE melt is The gear-type PP / PE composite staple fiber spun yarn is obtained by cooling and forming the gear-type PP / PE composite staple fiber. PE composite short fiber, the PP component in the gear-type PP / PE composite short fiber is di...

Embodiment 1

[0051] (1) Process PP slices and PE slices through their respective hoppers, extruders, metering pumps and filtration systems to obtain PP melts and PE melts, and then send the PP melts and the PE melts into the The spinning box is used for spinning, and after being conveyed by their own independent melt distribution system, they are compounded and extruded at the spinneret hole of the gear-shaped spinneret to form a fine stream of PP / PE melt, and the fine stream of the PP / PE melt is The gear-type PP / PE composite staple fiber spun yarn is obtained by cooling and forming the gear-type PP / PE composite staple fiber. PE composite short fiber, the PP component in the gear-type PP / PE composite short fiber is distributed on the gear-shaped bracket part of the gear-type PP / PE composite short fiber, and the PE component is distributed on the peripheral side of the gear-shaped bracket part The interdental filling part, and the mass ratio of PP component to PE component is 60:40.

[005...

Embodiment 2

[0062] (1) Process PP slices and PE slices through their respective hoppers, extruders, metering pumps and filtration systems to obtain PP melts and PE melts, and then send the PP melts and the PE melts into the The spinning box is used for spinning, and after being conveyed by their own independent melt distribution system, they are compounded and extruded at the spinneret hole of the gear-shaped spinneret to form a fine stream of PP / PE melt, and the fine stream of the PP / PE melt is The gear-type PP / PE composite staple fiber spun yarn is obtained by cooling and forming the gear-type PP / PE composite staple fiber. PE composite short fiber, the PP component in the gear-type PP / PE composite short fiber is distributed on the gear-shaped bracket part of the gear-type PP / PE composite short fiber, and the PE component is distributed on the peripheral side of the gear-shaped bracket part The interdental filling part, and the mass ratio of PP component to PE component is 60:40.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com