Comprehensive steel structure lifting appliance based on BIM technology and construction method

A steel structure, comprehensive technology, applied in the direction of building structure, load hanging components, building material processing, etc., can solve problems such as unfavorable promotion and implementation, long actual construction time, etc. The effect of improving efficiency and reasonable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

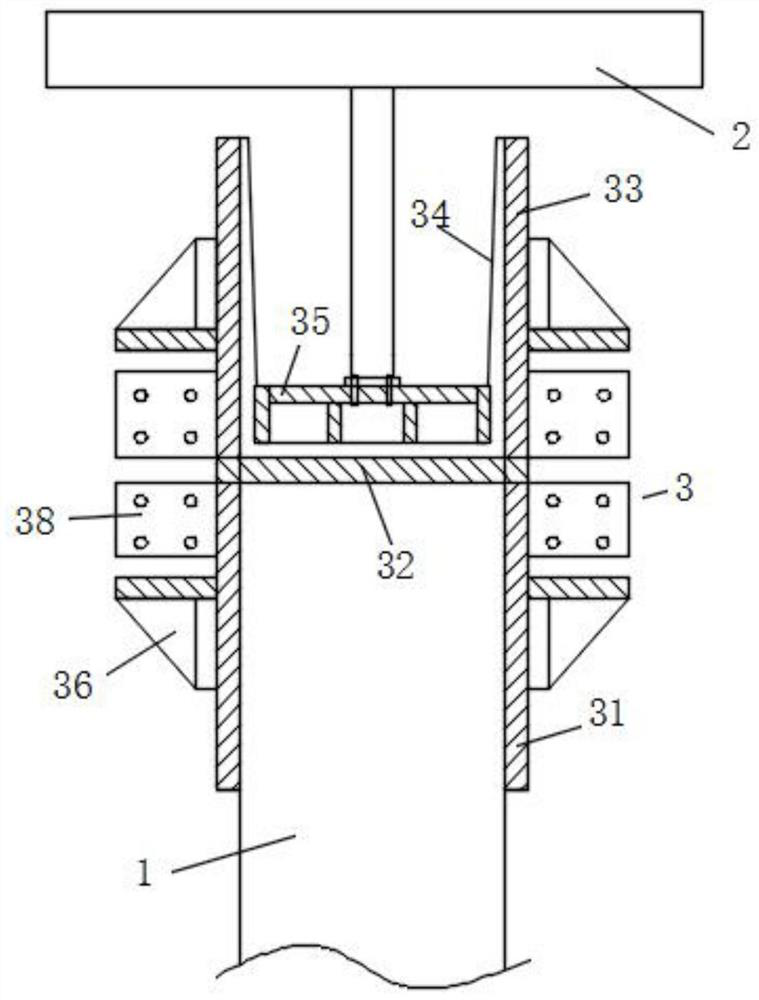

[0028] like Figure 1 to Figure 3 As shown, a comprehensive steel structure spreader based on BIM technology includes a steel structure column 1, a hanger body 3 connected to the steel structure column 1, and a boom 2 detachably connected to the hanger body 3 through bolts , the hanger body 3 is fixedly installed with a positioning structure for connecting the steel structure column 1 on the upper side and the lower side. Use the positioning structure to quickly install the upper steel structure 1, use the hanger body 3 to hoist the steel structure column 1, and at the same time serve as a connecting device for connecting the upper and lower steel structure columns 1 during installation, so as to realize efficient and safe implementation of the spreader , can also guarantee the shear and torsional capacity of its connecting nodes.

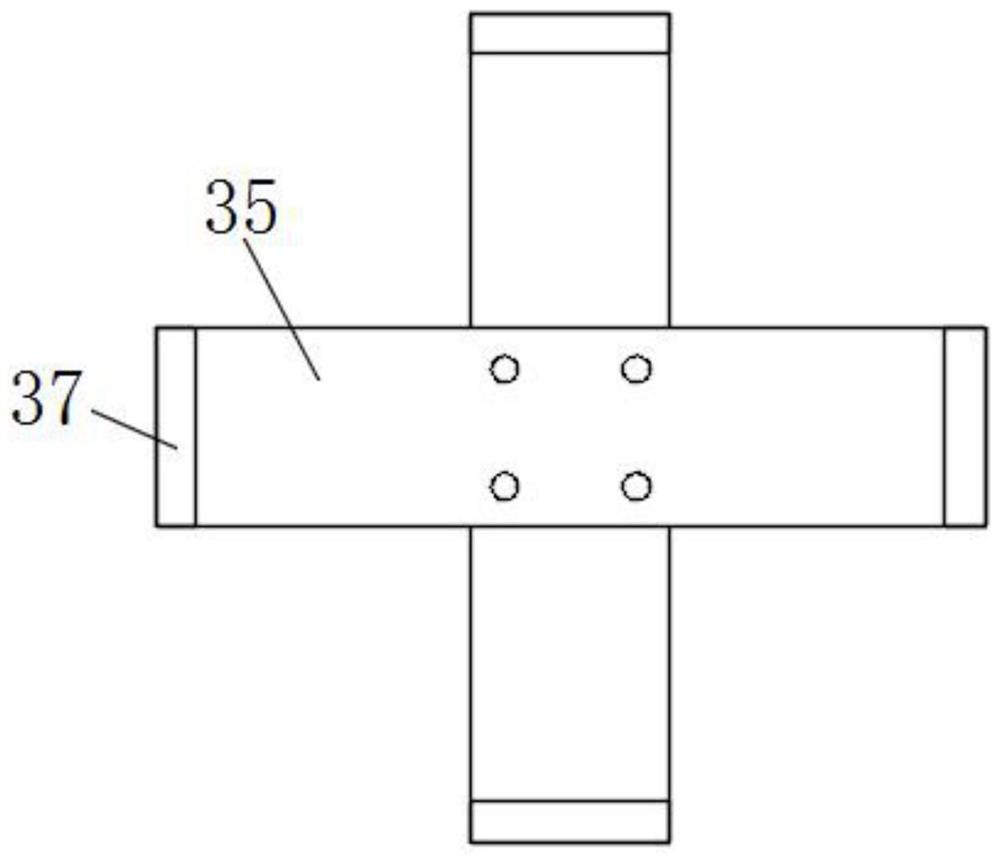

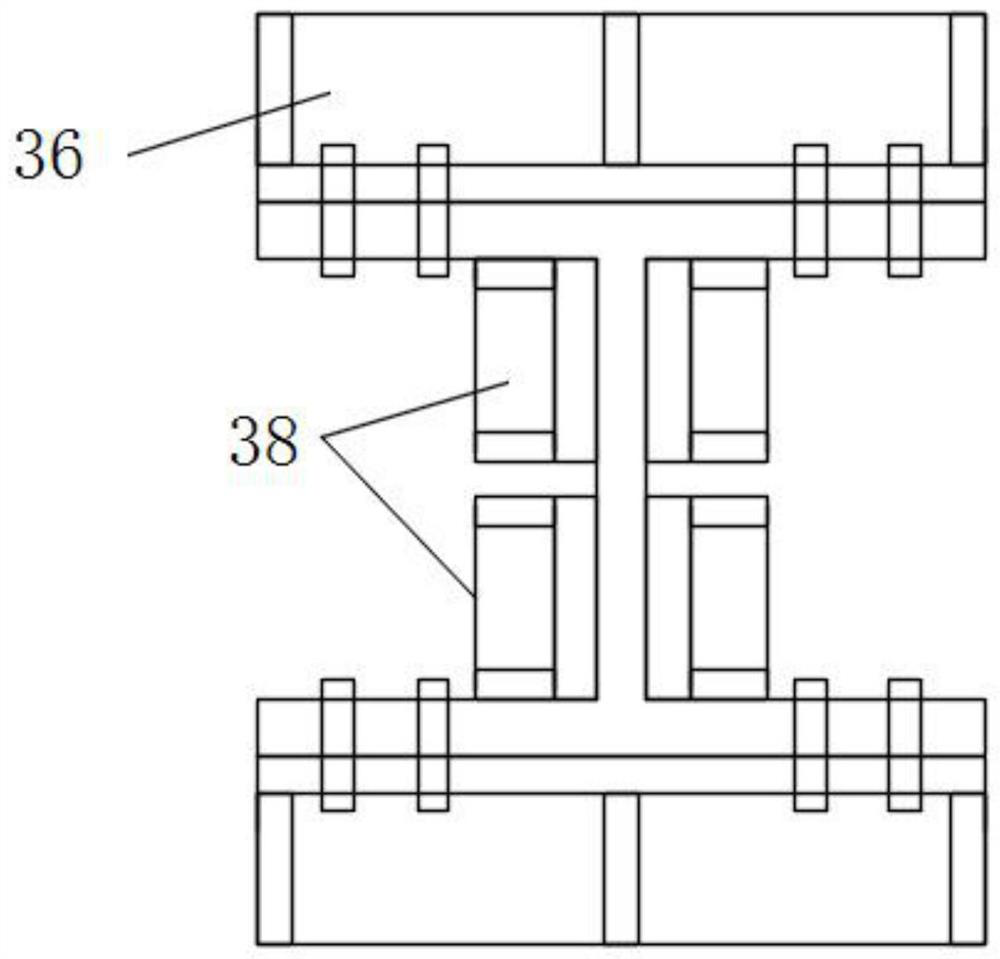

[0029] In a further preferred solution, the hanger body 3 includes a sheath 31 adapted to the outside of the steel structure column 1 and bolted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com