Flocculent autotrophic denitrification composite material and preparation method thereof

A technology of autotrophic denitrification and composite materials, which is applied in the field of flocculent autotrophic denitrification composite materials and its preparation, can solve the problems of small specific surface area between sulfur and sewage, affect sewage treatment efficiency, and small sulfur particle size, and achieve reduction The effect of increasing the inert inorganic components of the small sludge, avoiding the loss of sulfur, and reducing the suspended solids in the effluent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Take 100.0g of granular sulfur, and melt the granular sulfur into liquid sulfur at a temperature of 150°C-155°C. Weigh 125.0g of heavy calcium carbonate powder (200 mesh), add the calcium carbonate powder into the liquid sulfur, mix thoroughly and evenly. The mixed slurry is naturally cooled in a mold, and then crushed into a 325-mesh powdered sulfur-calcium carbonate integrated compound by a pulverizer.

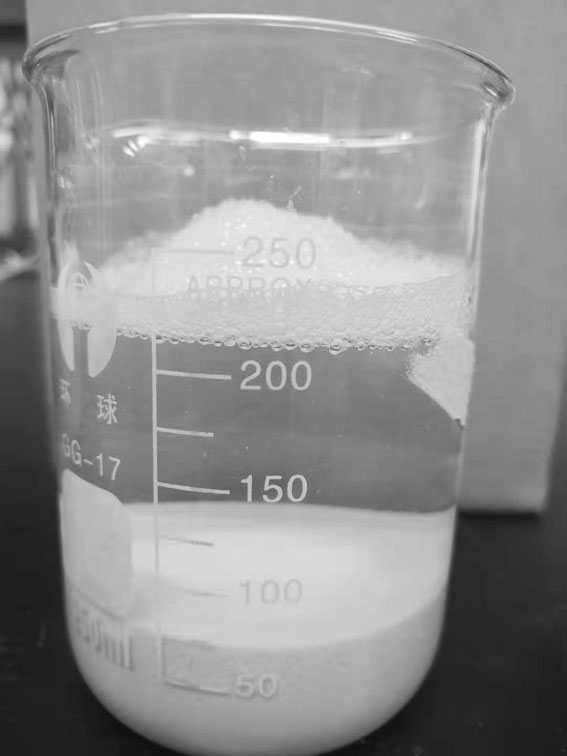

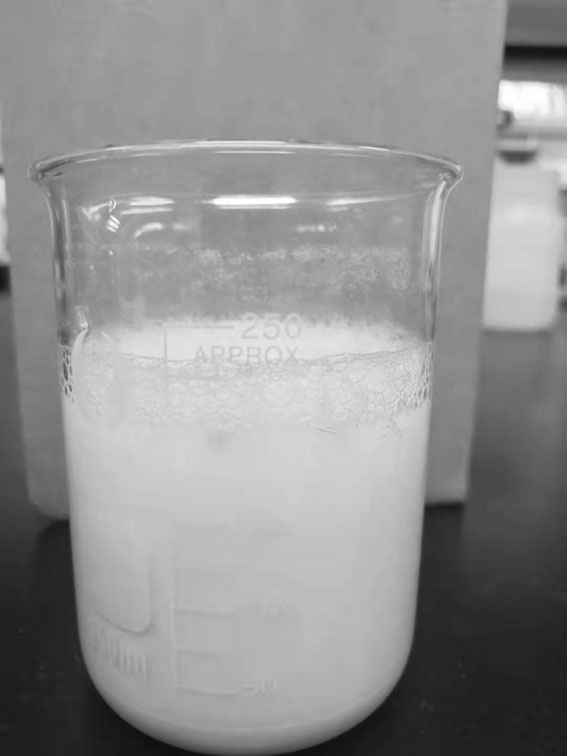

[0076] Take 200.0 g of sulfur-calcium carbonate integrated composite powder, 1.0 g of sodium dodecylbenzenesulfonate, 0.2 g of organic silicon wetting agent, 8.0 g of sodium bicarbonate, and 5.0 g of ferric chloride. The above powder is completely dispersed in a mixer and mixed evenly to obtain a dry basis of flocculent autotrophic denitrification composite material. Then add the whole weight of the dry base 2 into 2L of tap water, fully mix and dissolve, and stir to obtain the flocculent autotrophic denitrification and denitrification material of this embodiment. A...

Embodiment 2

[0080] Take 200.0g of granular sulfur, and melt the granular sulfur into liquid sulfur at a temperature of 150°C-155°C. Weigh 100.0g of heavy calcium carbonate powder (400 mesh), add the calcium carbonate powder into the liquid sulfur, mix thoroughly and evenly. The mixed slurry is naturally cooled in a mold, and then pulverized into a 200-mesh powdered sulfur-calcium carbonate integrated compound by a pulverizer.

[0081] Take 300.0g of sulfur-calcium carbonate integrated composite powder, 1.5g of sodium dodecylbenzenesulfonate, 0.4g of organic silicon wetting agent, 10.0g of sodium bicarbonate, 10.0g of polyferric sulfate, and put the above powder in the mixer Completely disperse and mix evenly to obtain the dry basis of the flocculent autotrophic denitrification composite material. Then add the whole mass of the dry base 2 into 5L tap water, fully mix and dissolve, and stir to obtain the flocculent autotrophic denitrification and denitrification material of this embodiment...

Embodiment 3

[0086] Take 400.0g of granulated sulfur, and melt the granulated sulfur into liquid sulfur at a temperature of 150°C-155°C. Weigh 25.0g of heavy calcium carbonate powder (800 mesh), add the calcium carbonate powder into the liquid sulfur, mix thoroughly and evenly. The mixed slurry is naturally cooled in a mold and broken into irregular particles of 1-10mm.

[0087] Take 400.0g of sulfur-calcium carbonate integrated particles, 3.2g of sodium dodecylbenzenesulfonate, 0.8g of organic silicon wetting agent, 16.0g of sodium bicarbonate, 15.0g of polyaluminum chloride, and 2L of tap water. Grind and disperse the above-mentioned powder in an experimental colloid mill, and mix evenly to obtain a dry basis of flocculent autotrophic denitrification composite material. Then add all the above weights on a dry basis to 3L of tap water, fully mix and dissolve, and stir to obtain the flocculent autotrophic denitrification and denitrification material of this embodiment. After standing sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap