Method for controlling impurities in pipericide

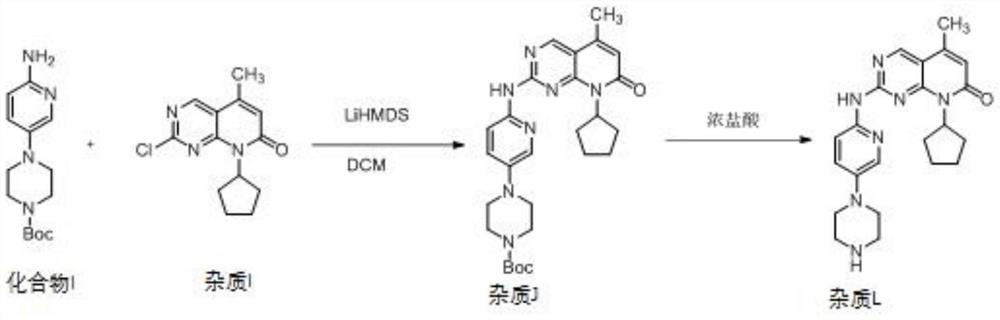

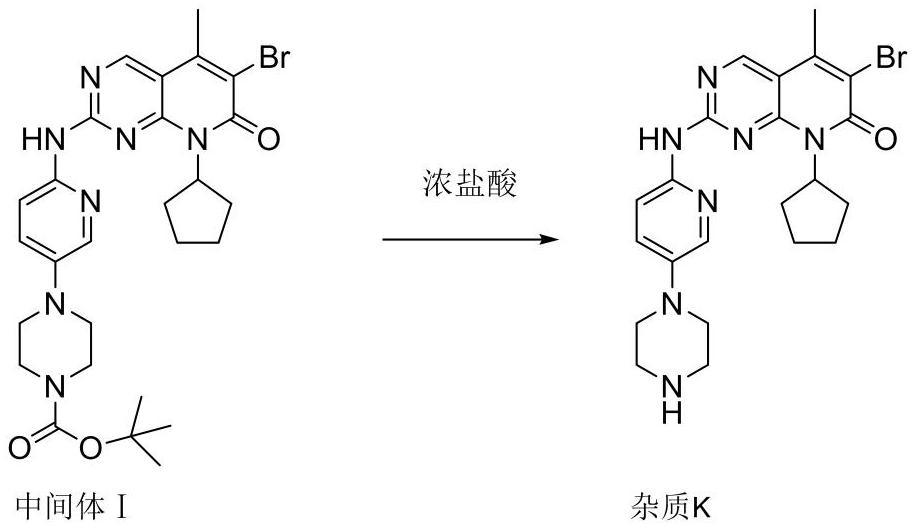

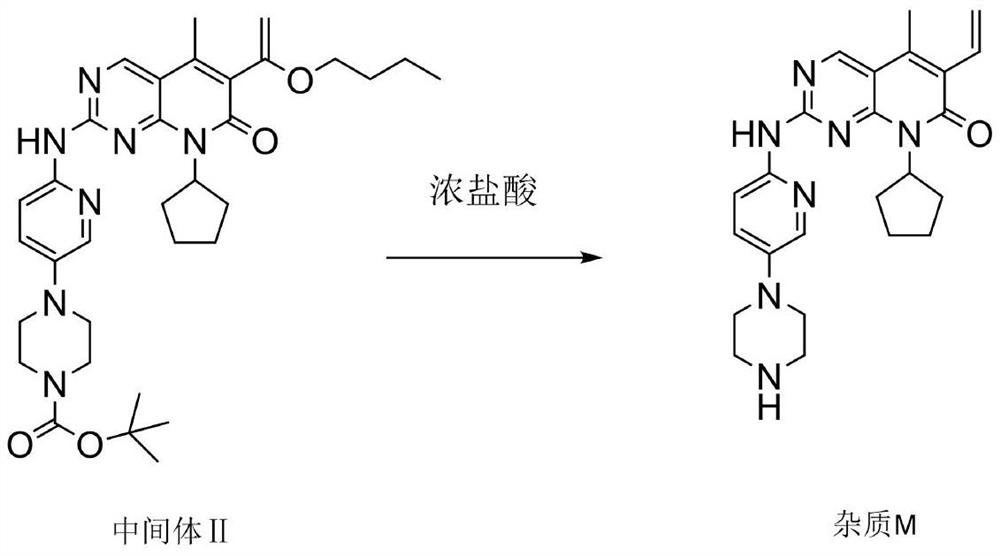

A technology of piperbocilide and a control method, which is applied in the field of impurity control in breast cancer drug piperbacillide, can solve problems such as poor impurities and low product purity, and achieve the effects of excellent quality, high purity and simple control method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] In the present embodiment, the purity of each intermediate is controlled as follows:

[0074] The purity of intermediate I is as follows: the compound I content is 0.4%, the compound II content is 1.5%, the largest single unknown impurity content is 1.2%, and the total impurity content is 3.4%.

[0075] The purity of intermediate II is as follows: the content of intermediate I is 0.1%, the largest single unknown impurity content is 1.0%, and the total impurity content is 2.3%.

[0076] The purity of palbociclib salt is as follows: the content of impurity L contained is 0.1%, the content of impurity K shall not exceed 0.1%, the content of impurity M is 0.2%, the content of impurity N is 0.2%, the content of the largest single unknown impurity is 0.1%, and the content of total impurities is 0.8%. .

[0077] The content of the generated final product palbociclib and the content of impurities contained therein were detected, and the results are shown in Table 1.

Embodiment 2

[0079] In the present embodiment, the purity of each intermediate is controlled as follows:

[0080] The purity of intermediate I is as follows: the compound I content is 0.3%, the compound II content is 1.1%, the largest single unknown impurity content is 0.9%, and the total impurity content is 2.7%.

[0081] The purity of intermediate II is as follows: the content of intermediate I contained is 0.1%, the largest single unknown impurity content is 0.9%, and the total impurity content is 1.8%.

[0082] The purity of palbociclib salt is as follows: the content of impurity L is 0.1%, the content of impurity K is 0.1%, the content of impurity M is 0.1%, the content of impurity N is 0.2%, the content of the largest single unknown impurity is 0.1%, and the content of total impurities is 0.7%.

[0083] The content of the generated final product palbociclib and the content of impurities contained therein were detected, and the results are shown in Table 1.

Embodiment 3

[0085] In the present embodiment, the purity of each intermediate is controlled as follows:

[0086] The purity of intermediate I is as follows: the compound I content is 0.3%, the compound II content is 1.4%, the largest single unknown impurity content is 1.1%, and the total impurity content is 3.5%.

[0087] The purity of intermediate II is as follows: the content of intermediate I is 0.2%, the largest single unknown impurity content is 0.9%, and the total impurity content is 3.0%.

[0088] The purity of the palbociclib salt is as follows: the impurity L content is 0.1%, and the impurity K content is 0.1%. The impurity M content is 0.1%, the impurity N content is 0.2%, the largest single unknown impurity content is 0.2%, and the total impurity content is 0.9%.

[0089] The content of the generated final product palbociclib and the content of impurities contained therein were detected, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com