A kind of dielectric material and its manufacturing method

A technology of dielectric materials and manufacturing methods, applied in the field of dielectric materials and their manufacturing, can solve the problems of cumbersome operation, affecting performance, weak industrialization ability, etc., and achieve the effect of simplifying the process flow and improving production efficiency

Active Publication Date: 2022-05-31

EAST CHINA UNIV OF SCI & TECH

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the high production cost and immature industrialization technology, Lunbo lens antenna has not been widely used yet

[0003] The application number is CN 201911238076.7, the Chinese patent titled "Longbo Lens Production Method Without Using Adhesive", the application number is CN 201910225149.2, the Chinese patent titled "Longbo Lens Production Method", the application number is CN 201811615162.0 , a Chinese patent titled "All-Medium Multi-beam Scanning Luneburg Lens Structure and Printing Method Suitable for 3D Printing", application number CN 201910686927.8, a Chinese patent titled "A Production Method of Lunebo Lens", application number A Chinese patent with CN 201910683233.9 titled "A Production Method for a Stacked Luneburg Lens", and a Chinese patent with application number CN 202010327192.2 titled "A Spherical Dielectric Material and Its Production Method and Luneburg Lens" The patent discloses a variety of Lumber lens manufacturing methods, including: (1) one-time foaming after multi-layer wrapping, so that the dielectric constant gradient changes. The disadvantage is that the number of wrapping layers is small, and the dielectric constant does not gradually change. Obviously, can not meet the requirements

(2) Use 3D printing to splicing two hemispherical lenses, but the cost of 3D printing is too high, the industrialization ability is weak, and the preparation time is too long

(3) Adhesives are used to bond multi-layer granular materials into spherical Luneberg lenses. This method requires the use of a large amount of adhesives, pollutes the environment, and cannot ensure consistent bonding thickness, which has a great impact on performance and is cumbersome to operate.

(4) The granular material is made into a multi-layer hemisphere, and then spliced into a sphere. Although no adhesive is used, this technology cannot guarantee the stability of splicing, and the distribution of particles at the merged place is relatively uneven, which affects performance.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

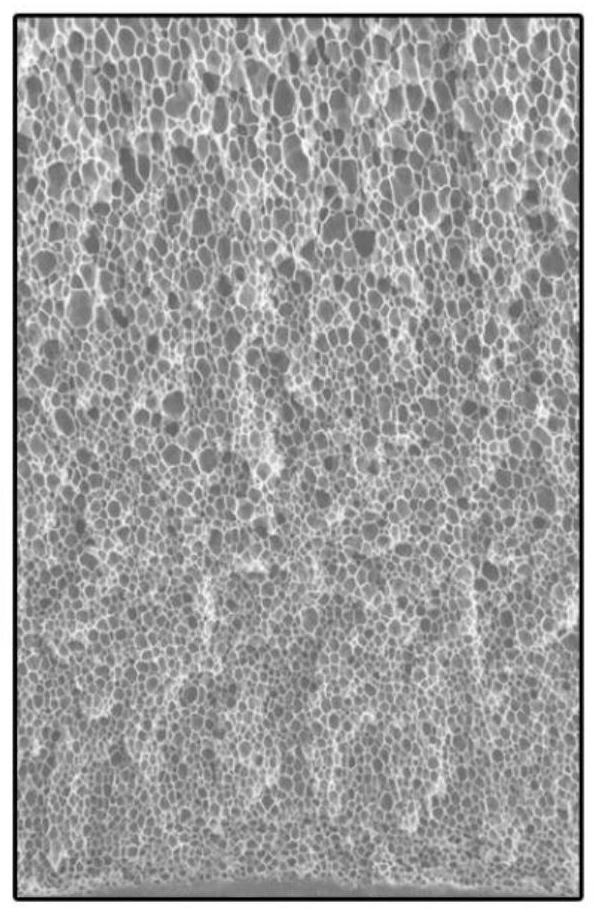

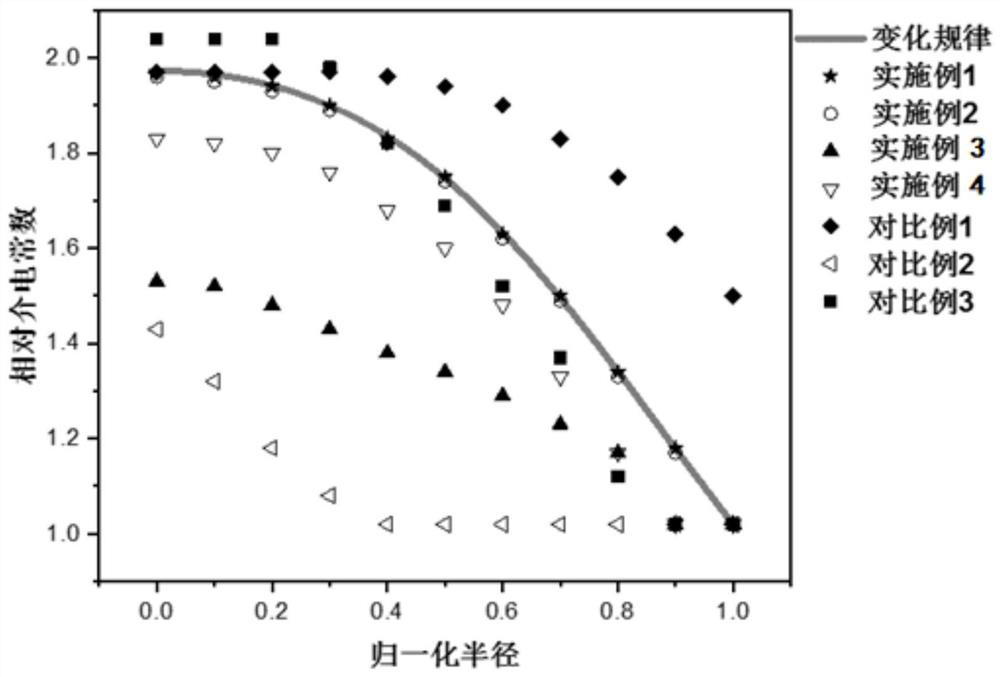

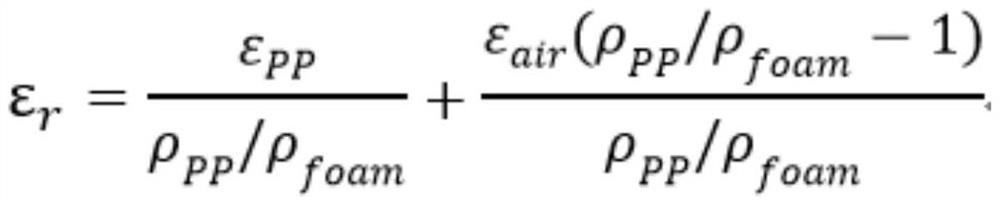

The invention provides a dielectric material and a manufacturing method thereof. The dielectric material includes: the foamed sphere obtained by one foaming at the second temperature T m Below 20°C to T m Below 5°C, filled with CO with a second pressure of 15-20MPa 2 Carry out foaming 30-3600min again in the mold cavity of the mold cavity, obtain dielectric material; Wherein, the specific step of described primary foaming comprises: the foaming material sphere that diameter is 20-800mm is at the first temperature T m below 80°C to T m Below 20°C, filled with CO with a first pressure of 15-20MPa 2 Foaming is carried out in the mold cavity to obtain foamed spheres. The present invention also provides the dielectric material produced by the above-mentioned production method. The manufacturing method can manufacture dielectric materials that are integrally formed and whose dielectric constant changes gradually.

Description

A kind of dielectric material and its manufacturing method technical field [0001] The present invention relates to the technical field of dielectric materials, particularly a dielectric material and a manufacturing method thereof. Background technique In 1944, the American mathematician Rudolf Karl Lüneburg proposed the model of Lunberg lens Lunberg lens, the An important basis of the model is that the dielectric constant of the sphere changes gradually from the inside to the outside according to a specific law. due to making The high-tech industrialization technology is immature, and the Lunberg lens antenna has not yet been widely used. Application number is CN 201911238076.7, title is " can not use the Lunberg lens production method of adhesive " Chinese patent, the application number is CN 201910225149.2, the Chinese patent titled "Production Method of Longbo Lens", application No. CN 201811615162.0, titled "All-media multi-beam scanning Lunberg lens structure...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08J9/12C08L23/12

CPCC08J9/122C08J2323/12C08J2203/06C08J2323/02C08J2367/02C08J2201/032B29C44/08C08J2201/02C08J2323/16C08J2323/20

Inventor 赵玲陈弋翀刘涛姚舜凌轶杰许志美胡冬冬

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com