Si2N2O wave transmission-heat insulation integrated inner lining material for microwave kiln, and preparation method of material

A microwave kiln and wave-transmitting technology, applied in the field of refractory materials, can solve the problems of affecting the high-temperature wave-transmitting performance, carbon residues, affecting the high-temperature dielectric properties of materials, etc., achieving easy control of the molding process, good heat insulation, and good pore structure. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

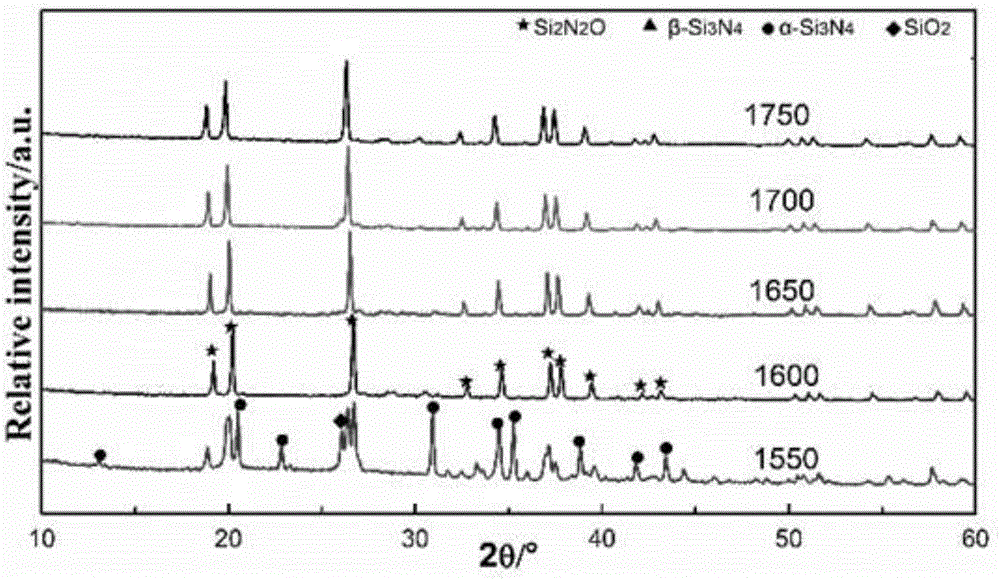

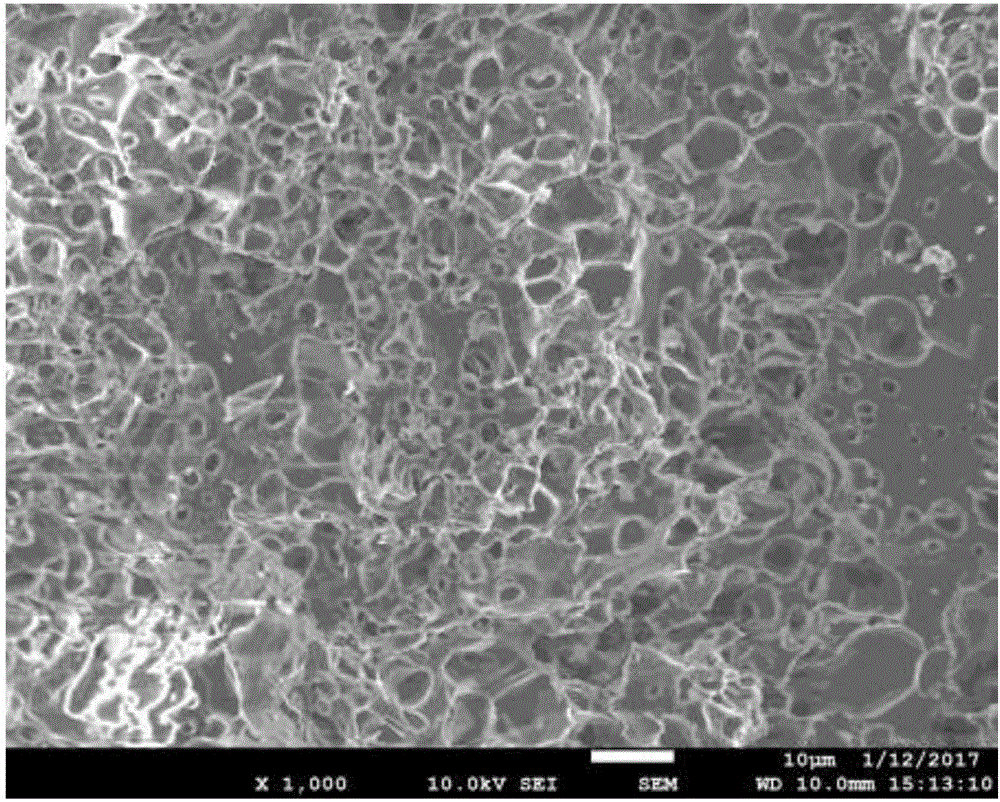

[0040] Mix 8mL tetraethyl orthosilicate with 4mL distilled water and 24ml ethanol evenly, pre-hydrolyze for 0.5h, slowly add 6g of amorphous silicon nitride powder into the above mixed solution, stir magnetically at 40°C for 4h, adjust the pH value to 9 with ammonia water; 40°C constant temperature water bath for 1h to obtain SiO 2 Uniformly coated amorphous silicon nitride gel. SiO 2 The uniformly coated amorphous silicon nitride gel was frozen in a super refrigerator at -40°C for 1 hour, then placed in a vacuum drying oven, dried at 60°C for 12 hours, and then cooled to room temperature. Under the protection of atmospheric nitrogen, freeze-dried SiO 2 The uniformly coated amorphous silicon nitride gel is heated from room temperature to 800°C within 2 hours, then from 800°C to 1400°C within 1 hour, then from 1400°C to 1600°C within 70 minutes and kept for 60 minutes, then cooled to room temperature Obtain Si for microwave kiln 2 N 2 O wave-transparent-heat-insulating int...

Embodiment 2

[0043] Mix 12mL of ethyl orthosilicate with 6mL of distilled water and 26ml of ethanol evenly, pre-hydrolyze for 1 hour, slowly add 6g of amorphous silicon nitride powder into the above mixed solution, stir magnetically at 40°C for 4 hours, adjust the pH value of the mixed solution to 8.5 with ammonia water; Then 40 ℃ constant temperature water bath for 1h, get SiO 2 Uniformly wrapped amorphous silicon nitride gel. SiO 2 The uniformly coated amorphous silicon nitride gel was frozen in a super refrigerator at -40°C for 1 hour, then placed in a vacuum drying oven, dried at 60°C for 12 hours, and then cooled to room temperature. Under the protection of atmospheric nitrogen, freeze-dried SiO 2 The uniformly coated amorphous silicon nitride gel is heated from room temperature to 800°C within 2 hours, then from 800°C to 1400°C within 1 hour, then from 1400°C to 1650°C within 85 minutes and kept for 70 minutes, then cooled to room temperature Obtain Si for microwave kiln 2 N 2 O...

Embodiment 3

[0046] Mix 9mL of ethyl orthosilicate with 5mL of distilled water and 25ml of ethanol evenly, pre-hydrolyze for 1.5h, add 6g of amorphous silicon nitride powder into the above mixed solution, stir magnetically at 40°C for 4h, adjust the pH value of the mixed solution to 8 with ammonia water; Then 40°C constant temperature water bath for 0.5h to obtain SiO 2 Uniformly coated amorphous silicon nitride gel. SiO 2 The uniformly coated amorphous silicon nitride gel was frozen in a super refrigerator at -40°C for 1 hour, then placed in a vacuum drying oven, dried at 60°C for 12 hours, and then cooled to room temperature. Under the protection of atmospheric nitrogen, freeze-dried SiO 2 The uniformly coated amorphous silicon nitride gel is heated from room temperature to 800°C within 2 hours, then from 800°C to 1400°C within 1 hour, then from 1400°C to 1700°C within 100 minutes and kept for 80 minutes, then cooled to room temperature Obtain Si for microwave kiln 2 N 2 O wave-tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com