Production method of PET high-temperature-resistant adhesive tape

A production method and high-temperature-resistant technology, which are used in adhesives, film/sheet-like adhesives, metal processing, etc., can solve the problem of long time-consuming, low processing efficiency, and cumbersome operation process for the slitting and processing of a single small tape master roll. problem, to achieve the effect of shortening the cutting time and improving the efficiency of the cutting process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

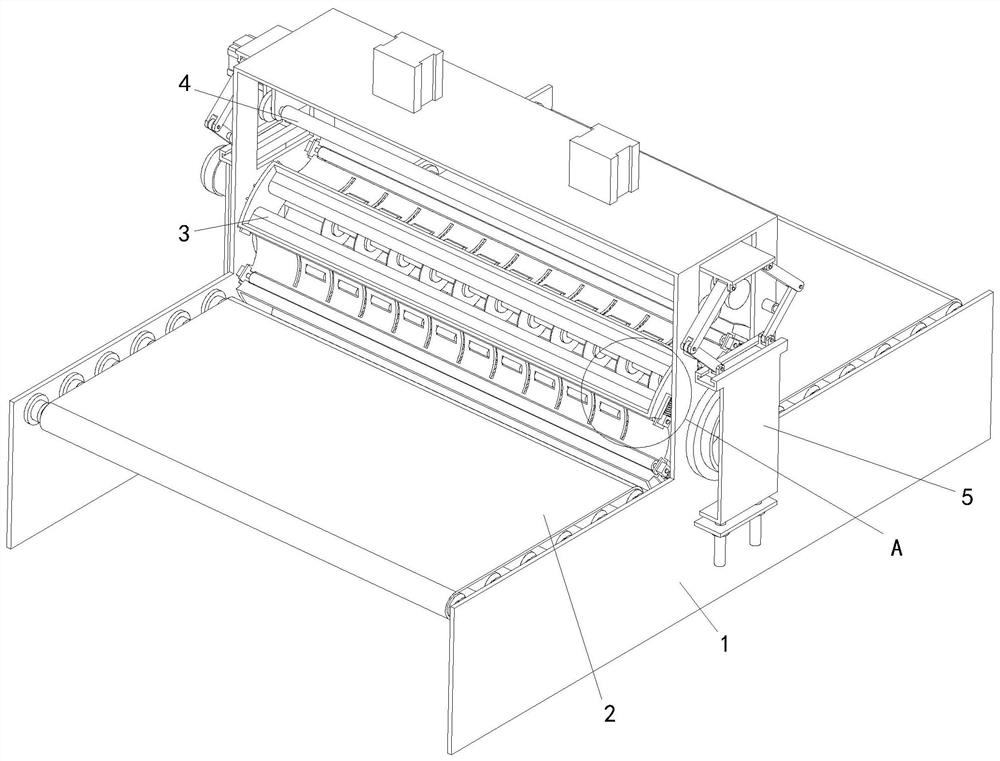

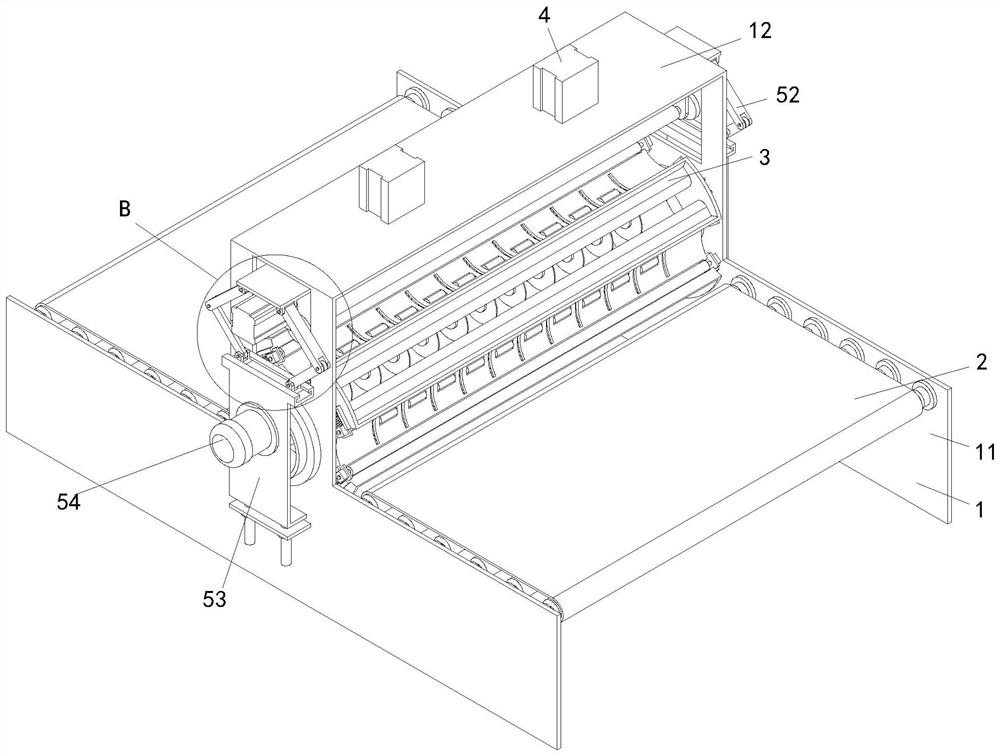

[0040] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and To facilitate its practice, but not as a limitation of the invention.

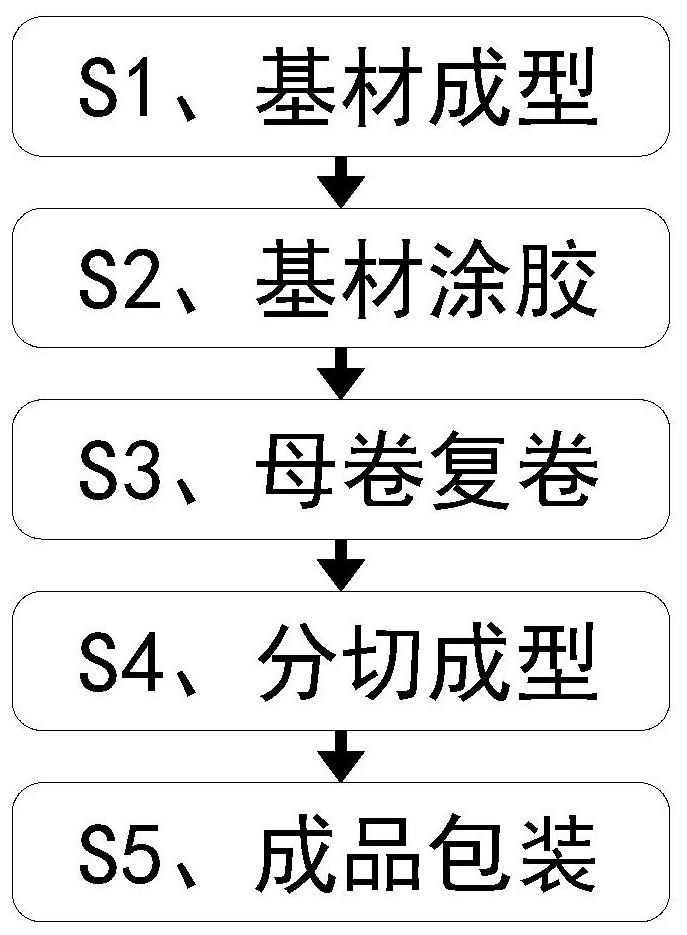

[0041] See attached Figure 1-9 Shown, a kind of production method of PET heat-resistant adhesive tape, production method specifically comprises the following steps:

[0042] S1. Substrate molding: use plastic granules and corresponding additives as raw materials, and use film blowing to form plastic film substrates;

[0043] S2. Substrate gluing: prepare the required glue according to the viscosity and purpose of the adhesive tape, and evenly coat the prepared glue on the plastic film substrate formed by blown film in step S1, and wind it up. Thereby preparin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com