Grinding wheel with beveled diamond tool bits

A kind of technology of diamond cutter head and bevel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

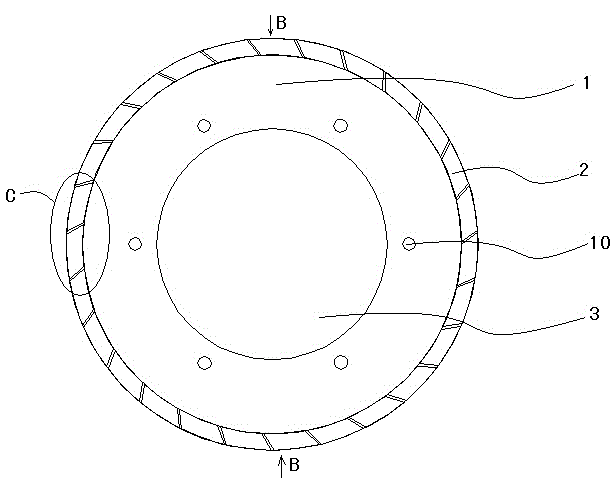

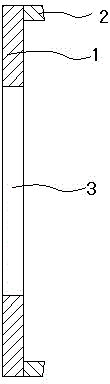

[0034]In this embodiment, a diamond grinding wheel is provided, which includes a ring-shaped mounting substrate 1 and a plurality of diamond bits 2 fixed on the edge of its upper surface. The diamond bits 2 are arranged in a ring shape, adjacent to each other. There is a gap 4 between the diamond segments 2: the diamond segments 2 are distributed along the radial direction of the mounting substrate 1 at an angle of 30°, and the distance between the diamond segment 2 and the center of the mounting substrate 1 has a basis From the width of gradual change, when being the width of gradual change, the farther away from the center of the grinding wheel, the wider the width, the outside of the diamond cutter head 2 is arc-shaped and the radius of the arc is the same as that of the mounting substrate 1 The radius difference is less than or equal to 5 mm; a mounting hole 3 is provided in the center of the mounting substrate 1 , and positioning holes 10 are also provided around the mount...

Embodiment 2

[0040] In this implementation, it is basically the same as Embodiment 1, the difference is that the diamond cutter head 2 has an equal width from the center of the mounting substrate 1, so that the specifications of each diamond cutter head are consistent, and when in use The amount of grinding is also consistent, avoiding the reduction of life due to severe wear of a certain part.

[0041] Moreover, in this embodiment, the radius of the outer arc surface of the cutter head is equal to the radius of the mounting substrate.

Embodiment 3

[0043] In this embodiment, in order to make the diamond grinding wheel have a better use effect, it is specially improved. Specifically, improve the diamond cutter head 2 on the grinding wheel, as attached Figure 6 , 7 , 8, the diamond cutter head 2 is provided with acute-angle helical teeth 21 inclined toward one side at least on the inner side of the mounting substrate 1 along the radial direction. In this way, during the grinding process, when the rotation direction of the diamond grinding wheel is consistent with the direction of the sharp helical teeth 21, the sharp helical teeth 21 first contact with the workpiece, which can cut quickly, thereby improving the cutting efficiency. Refer to attached figure 1 At present, the traditional diamond grinding wheel adopts the structure of the cutter head as a flat tooth. When the structure of this flat tooth is used for grinding, most of the side of the cutter head is in contact with the workpiece, and the grinding effect is po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com