A device and method for eliminating steam film

A technology of steam film and lifting device, which is applied in the direction of quenching device, process efficiency improvement, furnace, etc., and can solve the problems of not being able to effectively remove the steam film and not forming a closed-loop control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

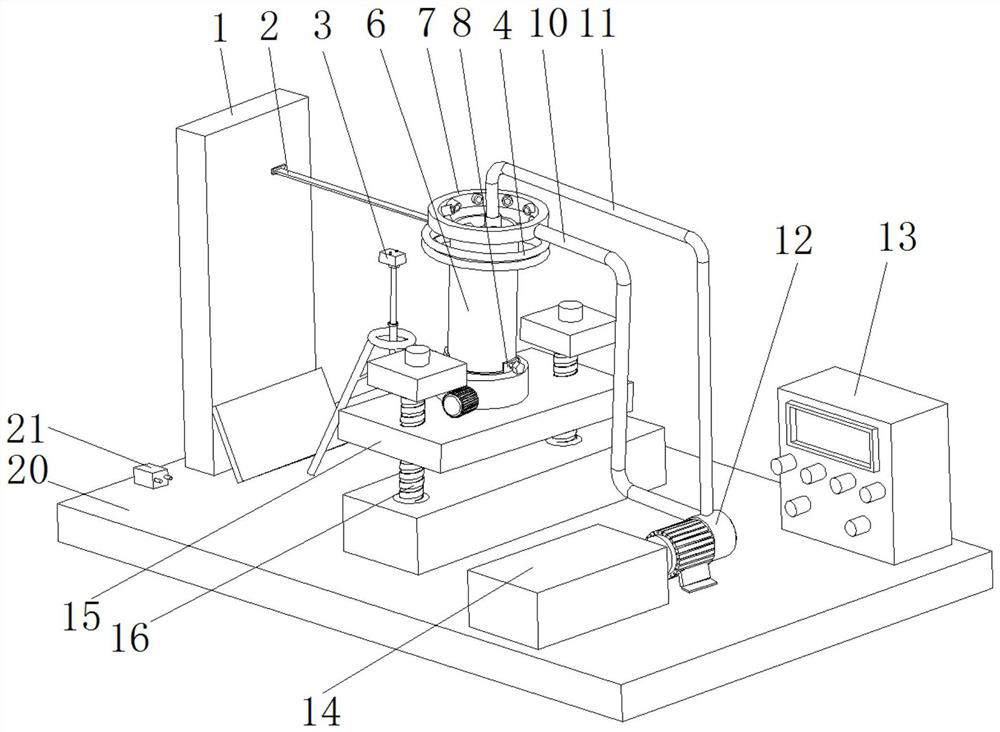

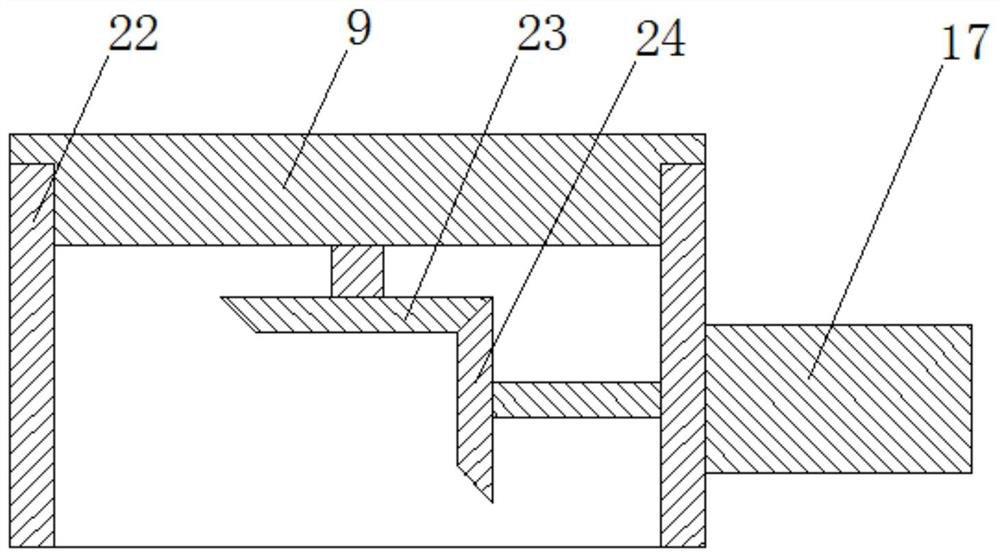

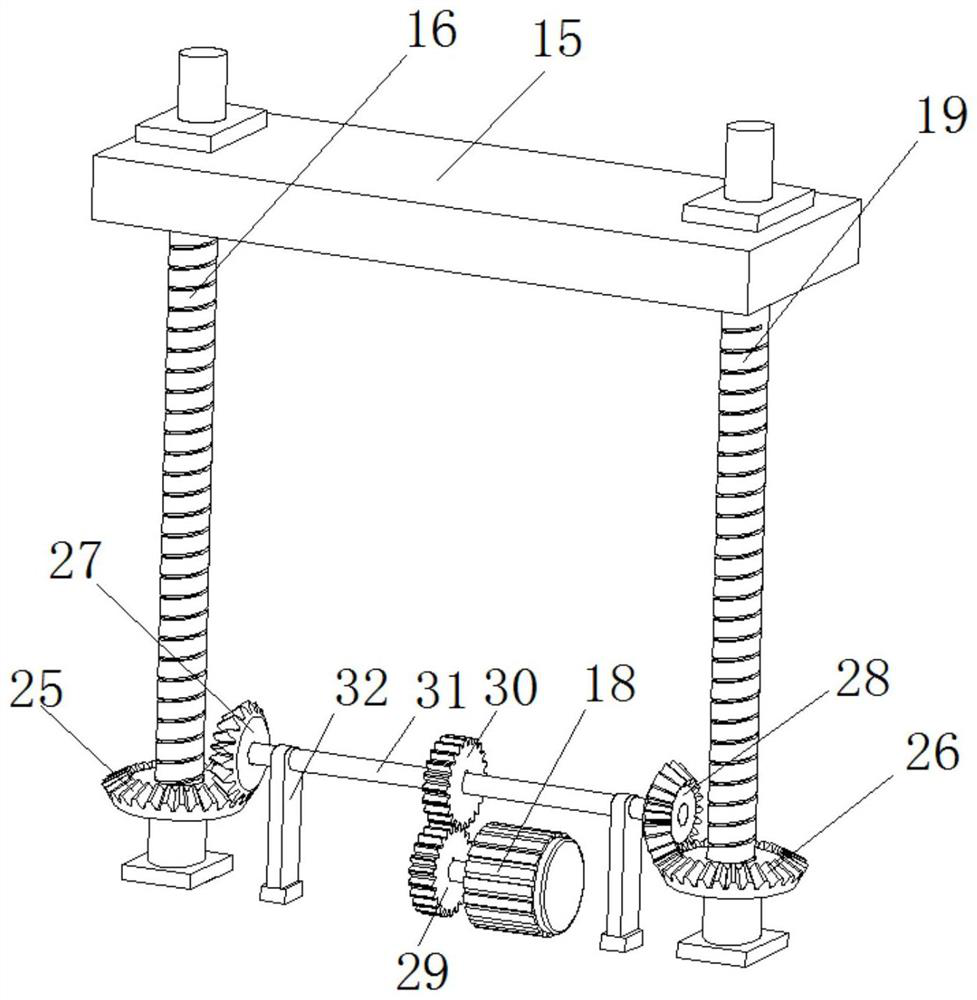

[0025] Such as Figure 1 to Figure 4 As shown, a device for eliminating steam film includes a support platform 1, a coil connection plate 2, a temperature measurement camera 3, an induction coil 4, a nozzle 5, a steel pipe 6, a cooling water sprayer 7, a rotating platform device, a lifting device, and a water pipe A10, water pipe B11, water pump 12, console 13, water storage tank 14, working platform 20 and sensor switch 21;

[0026] The center of the upper surface of the working platform 20 is provided with a lifting device, and the upper surface of the lifting platform 15 of the lifting device is provided with a rotating platform device. The temperature measurement camera 3 and the support platform 1, and the temperature measurement camera 3 is installed on the working platform 20 through the support frame, and the temperature change of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com