Underground jam releasing structure and underground jam releasing method

A sealing body and channel technology, used in wellbore/well components, wellbore/well valve devices, earth-moving drilling, etc., can solve problems such as nozzle jamming, affecting the normal production of oil and water wells, etc., and improve reliability. , restore production capacity, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

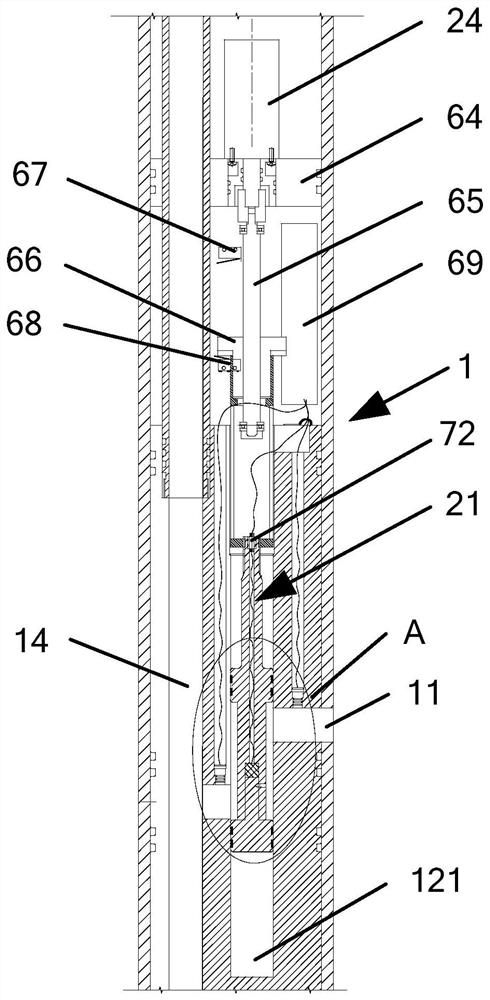

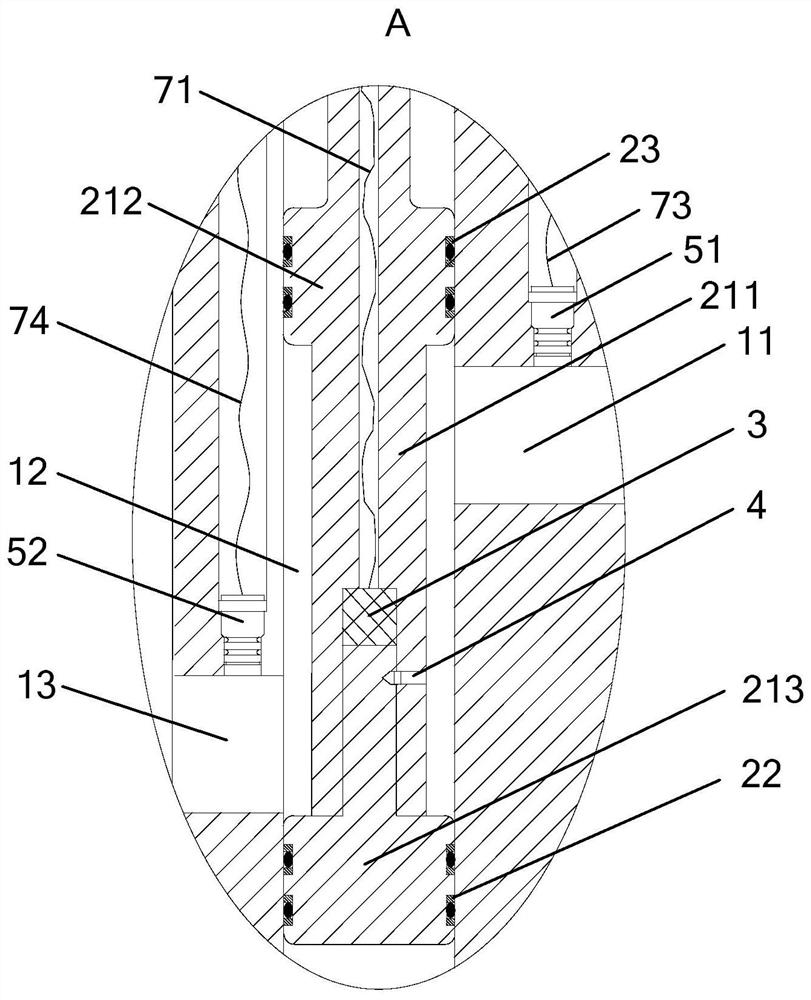

[0028] The embodiment of the present application provides an underground jamming structure, such as Figure 1 to Figure 4 As shown, the downhole jam release structure includes a pipe string base 1, a regulating valve assembly and a separation device; the pipe string base 1 is provided with a first passage 12 and a second passage 14, and the pipe string base 1 is also provided with a first opening 11 and the second opening 13, the fluid enters the second passage 14 through the first opening 11, the first passage 12, and the second opening 13 in turn; the regulating valve assembly includes a regulating valve 21, and the regulating valve 21 includes a valve body 211 and is arranged on the valve The lower sealing body 213 at the bottom of the body 211, the lower sealing body 213 is set to extend into the first passage 12 and can move in the first passage 12 to close or open the first passage 12; between the valve body 211 and the lower sealing body 213 A separation device is provi...

Embodiment 2

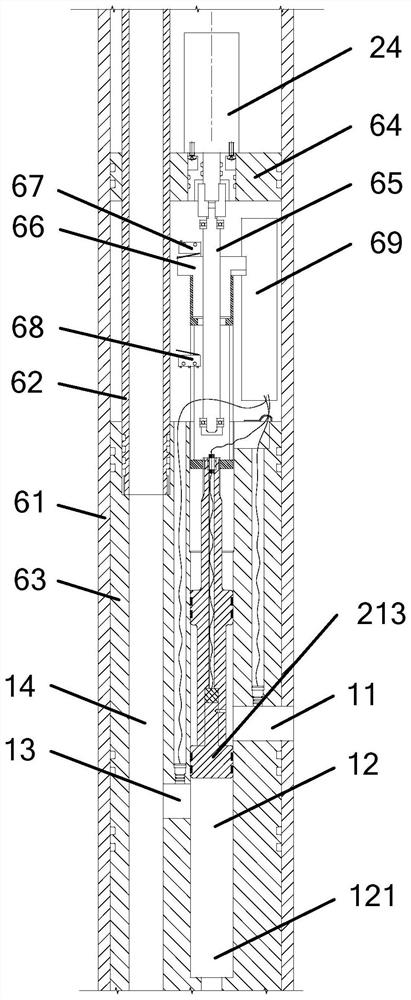

[0053] The downhole jam-releasing structure provided in the embodiment of the present application is the same as the main structure 63 in the first embodiment, and only the differences between the two are described here. The main difference between the downhole jam release structure provided in the embodiment of the present application and the first embodiment lies in the structure of the regulating valve 21 .

[0054] In an exemplary embodiment, a third sealing body is provided on the valve body 211, and the third sealing body is arranged between the upper sealing body 212 and the lower sealing body 213; after the lower sealing body 213 falls off from the valve body 211, The third sealing body is used to close or open the first channel 12 .

[0055] A third sealing body is provided to replace the lower sealing body 213 after the lower sealing body 213 is blasted off. When the fluid channel needs to be closed, the third sealing body is located between the first opening 11 and ...

Embodiment 3

[0059] The embodiment of the present application provides a kind of downhole solution method, the downhole solution method uses the downhole jamming solution structure in embodiment 1 or embodiment 2, comprises the following steps:

[0060] Measure the current value of the circuit where the drive motor 24 is located: the voltage can be sampled through a 1Ω resistor connected between the drive circuit and the motor, and the voltage on the resistor is measured by the voltage measurement module, and the voltage value is equal to the current value, such as Figure 5 shown.

[0061] When the current value reaches the first set value, drive the motor 24 to control the regulating valve 21 to go up and down to confirm whether the regulating valve 21 is in a stuck state: judge whether the regulating valve 21 is in a locked state by the current value, when the current value is greater than When the current is twice the normal working current, it means that the regulating valve 21 has be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com