Inclined shaft freezing and cooling capacity recovery device capable of improving safe operation of ammonia system without shutdown

A technology of cold energy recovery and system safety, which is applied in shaft equipment, well sinking, mining equipment, etc., can solve the problems of water resource waste and cost increase, and achieve the effect of avoiding waste, reducing operating costs, and improving utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

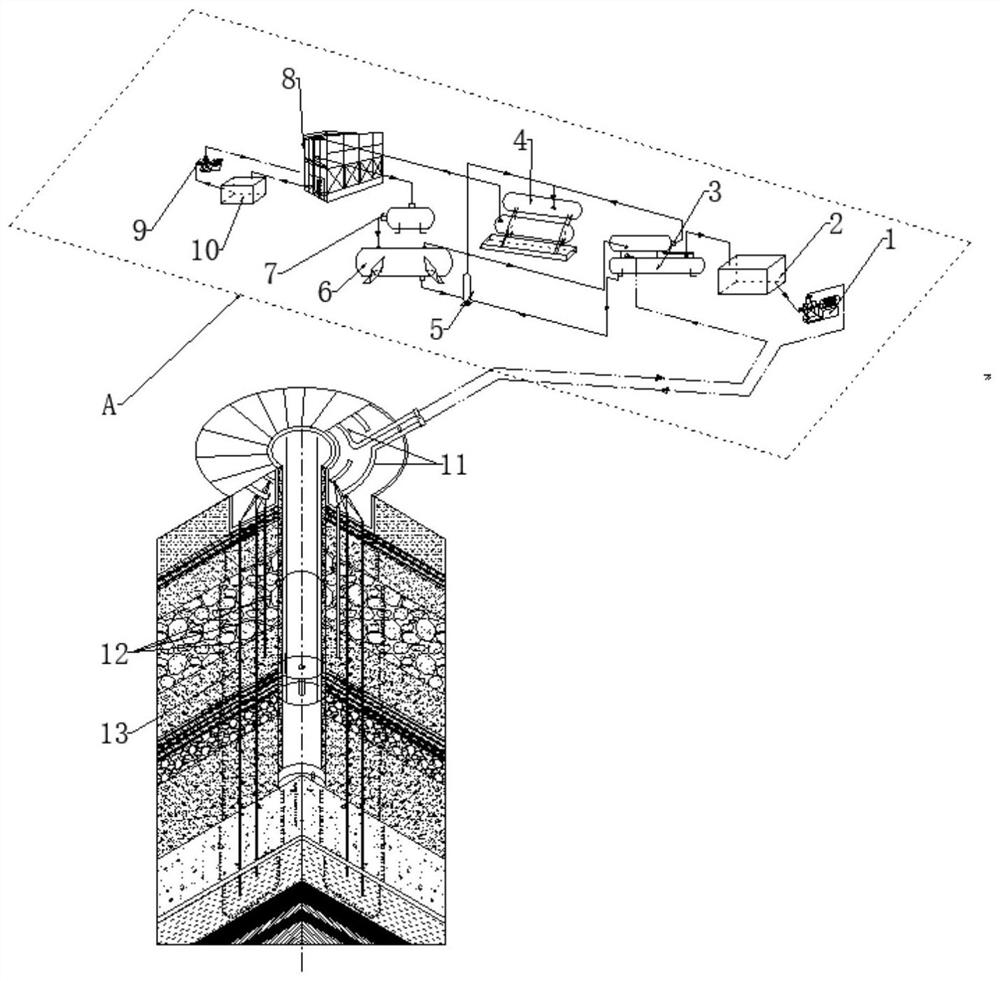

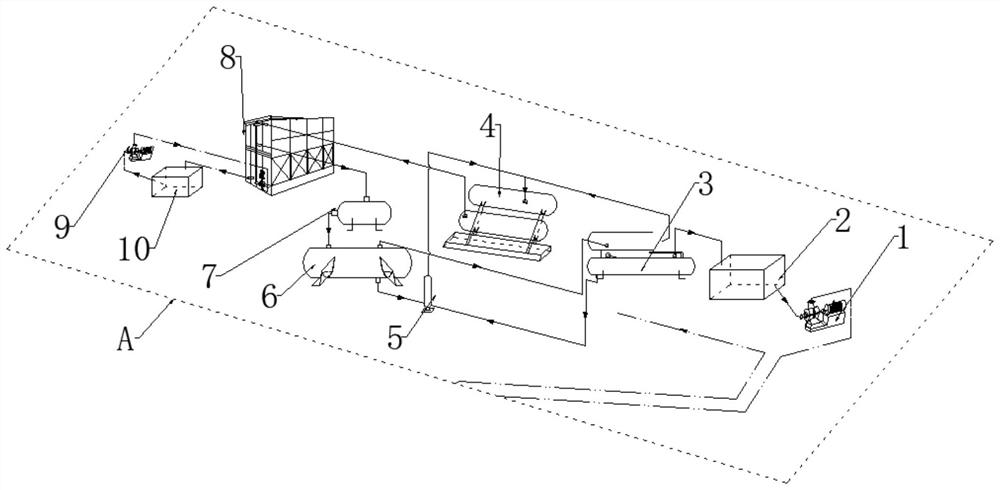

[0037] An inclined shaft freezing and cooling capacity recovery device that improves the safe operation of the ammonia system without shutting down, including a brine system, an ammonia system, a clean water system, and a cooling capacity extraction system for the frozen wall in the completed stage. The brine system provides cooling capacity for the frozen wall in the unfinished stage , The ammonia system provides cooling capacity to the low-temperature brine in the brine system, the clean water system provides cooling capacity to the high-temperature and high-pressure ammonia gas in the ammonia system, and the frozen wall cooling extraction system in the completed stage provides cooling capacity to the clean water system. The device lowers the temperature of the clean water cooling water in the clean water system by extracting the cooling capacity of the frozen wall in the completed stage, which can effectively improve the utilization efficiency of the stored cold capacity in t...

Embodiment 2

[0046] An inclined shaft freezing and cooling capacity recovery device that improves the safe operation of the ammonia system without shutting down, including a brine system, an ammonia system, a clean water system, and a cooling capacity extraction system for the frozen wall in the completed stage. The brine system provides cooling capacity for the frozen wall in the unfinished stage , The ammonia system provides cooling capacity to the low-temperature brine in the brine system, the clean water system provides cooling capacity to the high-temperature and high-pressure ammonia gas in the ammonia system, and the frozen wall cooling extraction system in the completed stage provides cooling capacity to the clean water system.

[0047] The structures of the brine system and the ammonia system of this embodiment are the same as those of Embodiment 1, see for details figure 1 and figure 2 . Such as Figure 4 As shown, the cooling capacity extraction system of the frozen wall in t...

Embodiment 3

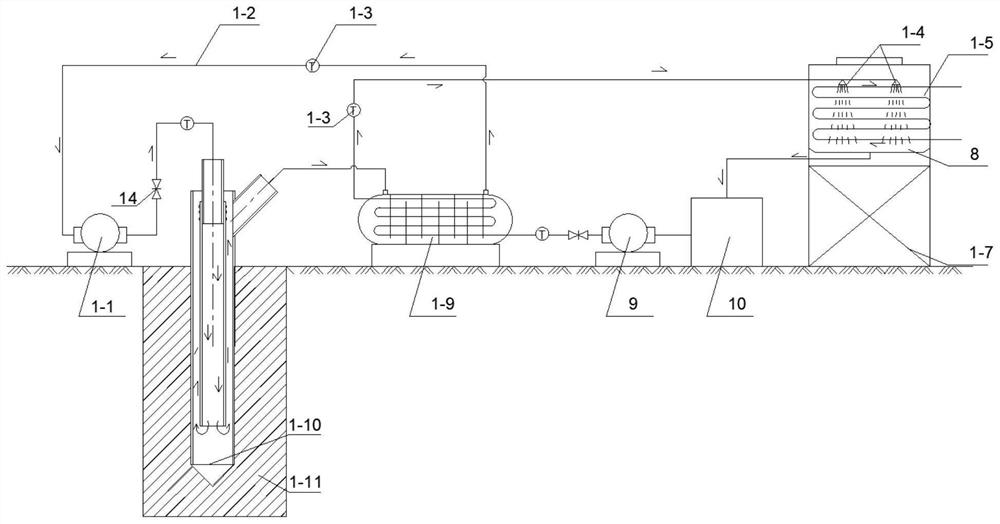

[0052] In this embodiment, in the inclined shaft freezing and cooling capacity recovery device for improving the safe operation of the ammonia system without stopping the machine, the structures of the brine system, the ammonia system and the frozen wall cooling capacity extraction system in the completed stage are the same as those in Example 2, and the clear water The difference between the system and Example 2 is that the way the clean water system provides cooling capacity to the high-temperature and high-pressure ammonia gas of the ammonia system is a closed type. The working principle of the closed water purification system is as follows: Figure 7 Shown, its specific structure see Figure 5 .

[0053] Such as Figure 5 As shown, the cooling capacity extraction system of the frozen wall in the completed stage includes the frozen wall 1-11 in the completed stage and the frozen pipe 1-10 in the completed stage; the clean water system includes a first clean water pump 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com