Method for dismantling and replacing temporary support of tunnel inverted arch

A temporary support and tunnel technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of tunnel water leakage and the impact of waterproof layer construction, and achieve the effect of ensuring waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

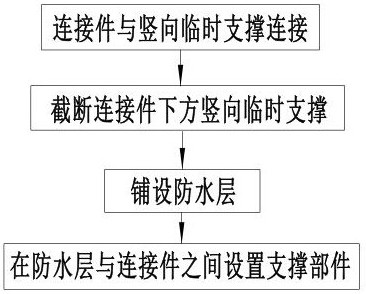

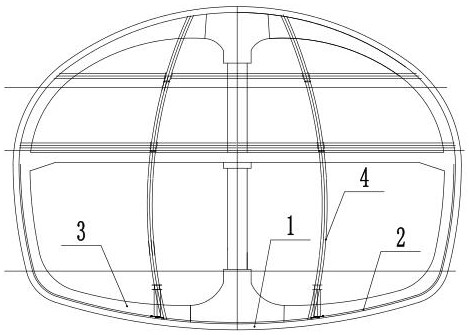

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the method for removing and replacing the temporary support of the tunnel inverted arch in this embodiment, the steps are as follows:

[0043] Step 1: According to the span of shallow-buried underground excavation subway station, the spacing of steel pipe columns, the thickness of the covering layer on the top of the station, and the load of temporary supports, comprehensively analyze and determine the longitudinal section length of the inverted arch lining and the location of the construction joint. The section length is usually two steel pipes. The distance between the pipe piles, the construction joint is set at a span of 1 / 4-1 / 5 from the steel pipe pile, and the connecting piece 5 is set on the vertical temporary support 4 after the segmentation, that is, the vertical temporary support 4 that needs to be cut off is set The connector 5, the length of the connector 5 needs to be greater than...

Embodiment 2

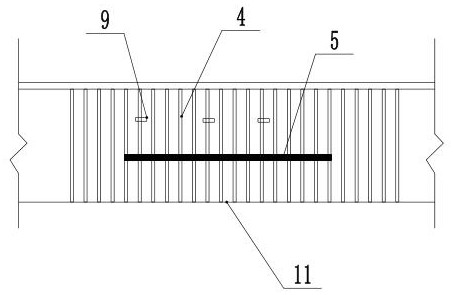

[0055] Such as image 3 As shown, in this embodiment, the difference from Embodiment 1 is that the step 1 also includes setting monitoring points on the vertical temporary support 4, and collecting the initial value of the settlement deformation of the monitoring point, wherein the initial value of the settlement deformation refers to The position information of the monitoring point can be used to calculate the settlement deformation of the tunnel through the position change of the monitoring point, so that the deformation of the tunnel can be monitored, the probability of tunnel collapse can be reduced, and the safety of construction can be improved.

[0056] Specifically, the height test steel bar 9 is bound on the monitoring point of the vertical temporary support 4, and the position change of the height test steel bar 9 is measured by a total station, so as to obtain the settlement deformation of the tunnel.

[0057] Further, in the step 2, each support beam of the vertica...

Embodiment 3

[0059] Such as Figure 8 As shown, in this embodiment, the difference from Embodiment 1 is that in the step 1, the connecting piece 5 includes a first connecting piece 51 and a second connecting piece 52, and the first connecting piece 51 and the second connecting piece 52 The two connectors 52 are respectively arranged on both sides of the vertical temporary support 4, so that both sides of the vertical temporary support 4 are supported by the connector 5, the supporting effect is better, and the stability of the tunnel structure is improved;

[0060] Wherein the first connecting piece and the second connecting piece are both made of I22 type steel, and are connected with the vertical temporary support 4 by welding;

[0061] Further, a first installation groove 41 is provided on one side of the vertical temporary support 4, the first connecting piece 51 is arranged in the first installation groove 41, and the first connecting piece 51 is connected with the first installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com