Multi-stage rubber torsion damper

A torsional shock absorber and shock absorber technology, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., can solve the problem that single-stage rubber torsional shock absorbers cannot effectively obtain reasonable stiffness changes and are difficult to effectively absorb vibrations Energy, idling noise and other issues, to achieve the effect of protecting safe operation, absorbing vibration energy, and eliminating idling noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

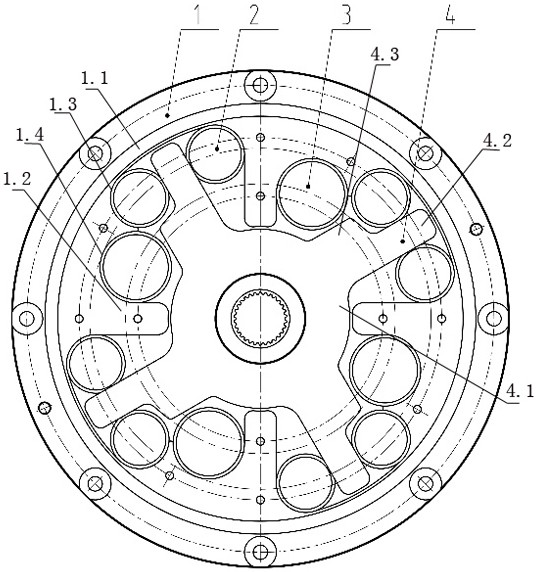

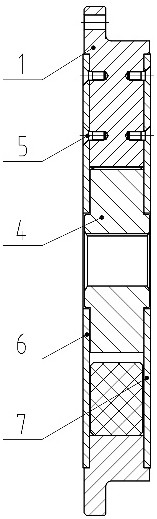

[0028] Such as Figure 1-2 As shown, the multi-stage rubber torsional shock absorber includes a shock absorber outer shell 1 and a shock absorber inner shell 4. The shock absorber outer shell 1 is connected to the engine flywheel, receives the torque transmitted by the engine, and absorbs vibration The inner casing 4 of the shock absorber is connected with the subsequent drive train components through the inner hole spline to transmit torque. The outer casing 1 of the shock absorber is set on the outside of the inner casing 4 of the shock absorber. Placed concentrically with the inner hole of the shock absorber inner shell 4, a shock absorber is arranged between the shock absorber outer shell 1 and the shock absorber inner shell 4, and the shock absorber outer shell 1 and the shock absorber inner shell 4 The torque is transmitted through the damping device.

[0029] In this embodiment, the inner shell 4 of the shock absorber includes a central disc body, and the outer ring of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com