Flow reducing and buffering structure of temperature self-adjusting three-channel ball valve based on temperature sensing spring

A temperature-sensing spring and self-adjusting technology, which is applied in the direction of valve absorbing fluid energy, multi-way valve, valve operation/release device, etc., can solve the problems of temperature control failure, small driving force, poor reliability, etc., to achieve The effect of suppressing shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

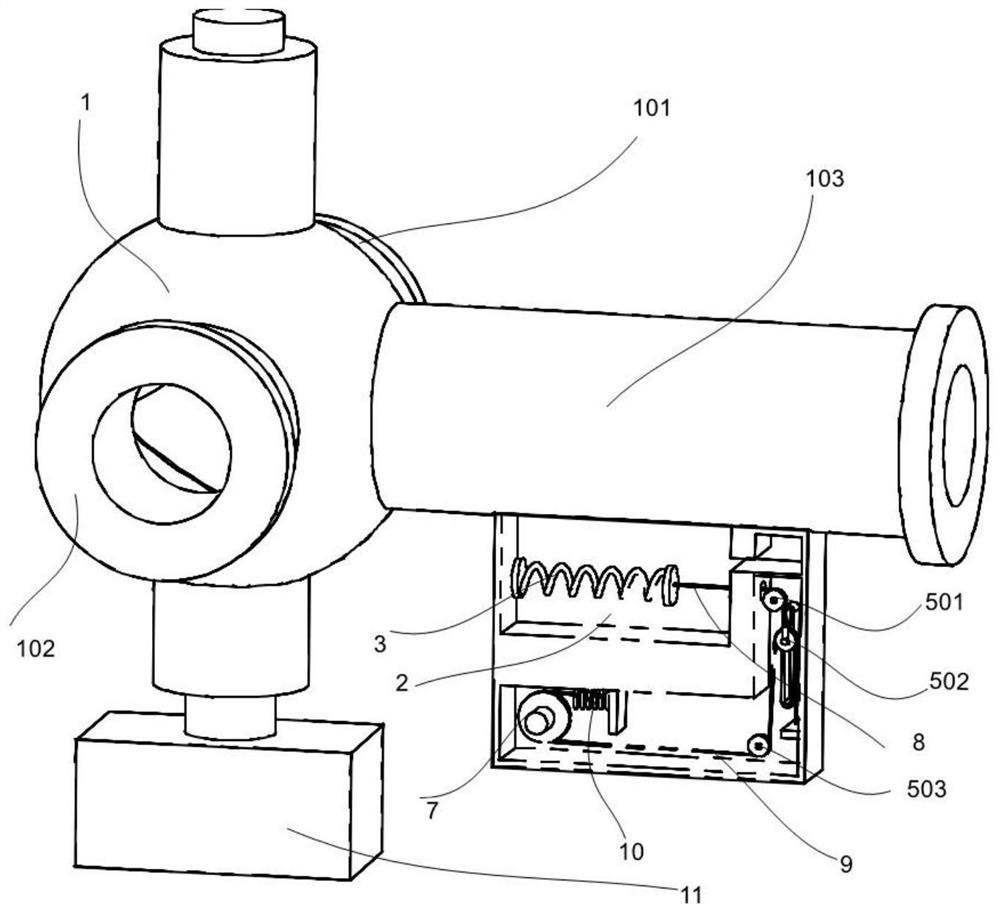

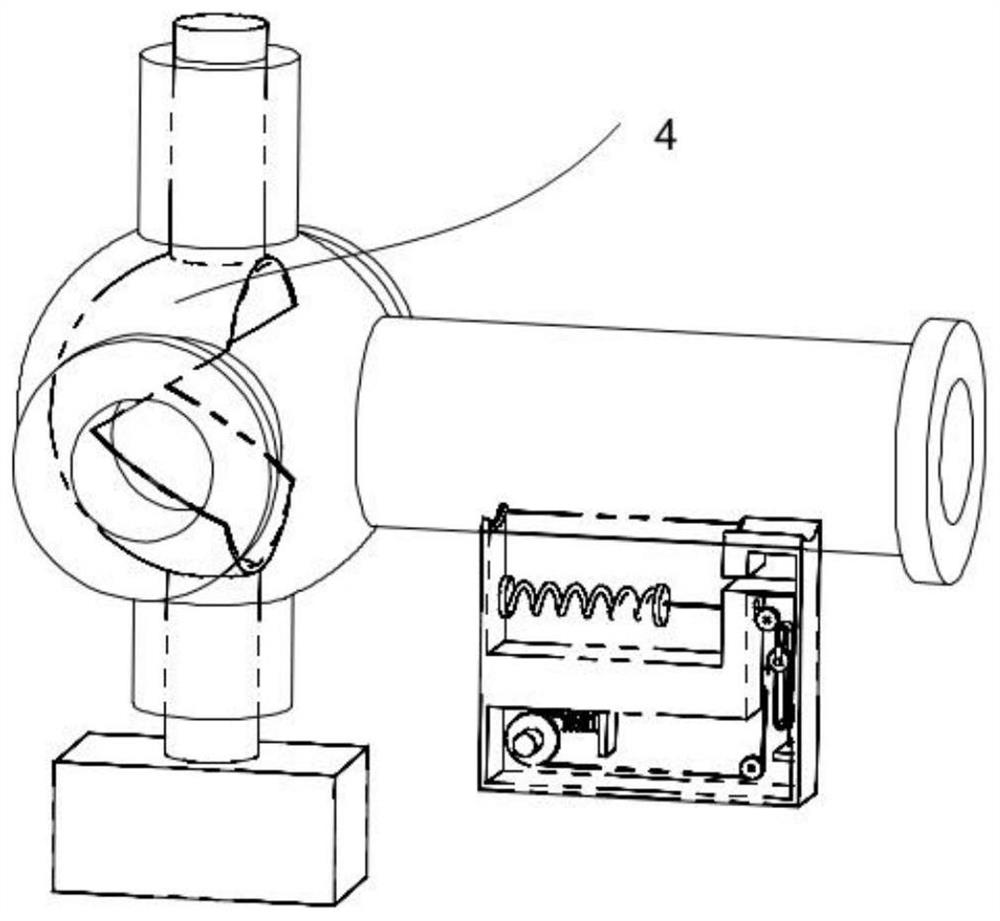

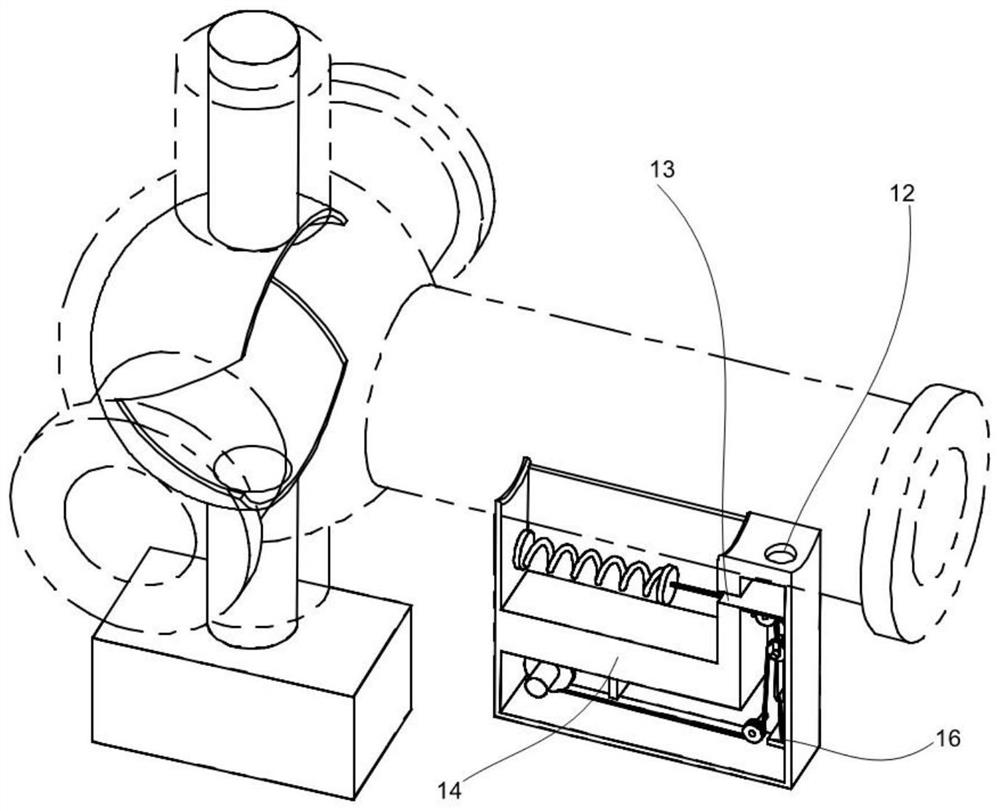

[0036] The relevant structure is described in detail below based on the drawings of the description:

[0037] see figure 1 , The temperature self-adjusting three-channel ball valve based on the temperature-sensitive spring includes a ball valve body 1, a temperature detection device 23, a driving device 11, a V-shaped ball assembly 4, and a control system. Wherein the ball valve body 1 comprises a hot water pipeline 101, a cold water pipeline 102, an outlet pipeline 103 and a spherical cavity structure respectively connected to the hot water pipeline 101, the cold water pipeline 102, and the outlet pipeline 103, wherein the hot water pipeline 101, the cold water pipeline 102, the outlet pipeline 103 are respectively located on the x positive axis, y negative axis, and y positive axis of the Cartesian coordinate system, and the respective central axes are perpendicular to each other. The origin of the Cartesian coordinate system is at the center of the spherical cavity structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com