A Medium and Small Boiler with Ultra-low NO x , CO emission gas burner

A technology for gas burners and small boilers, applied in the field of boiler combustion, can solve the problems of not considering low NOx emission and environmental protection requirements, unfavorable installation of low NOx burners, etc., to avoid carbon monoxide generation, stable and reliable combustion, and low NOx combustion emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

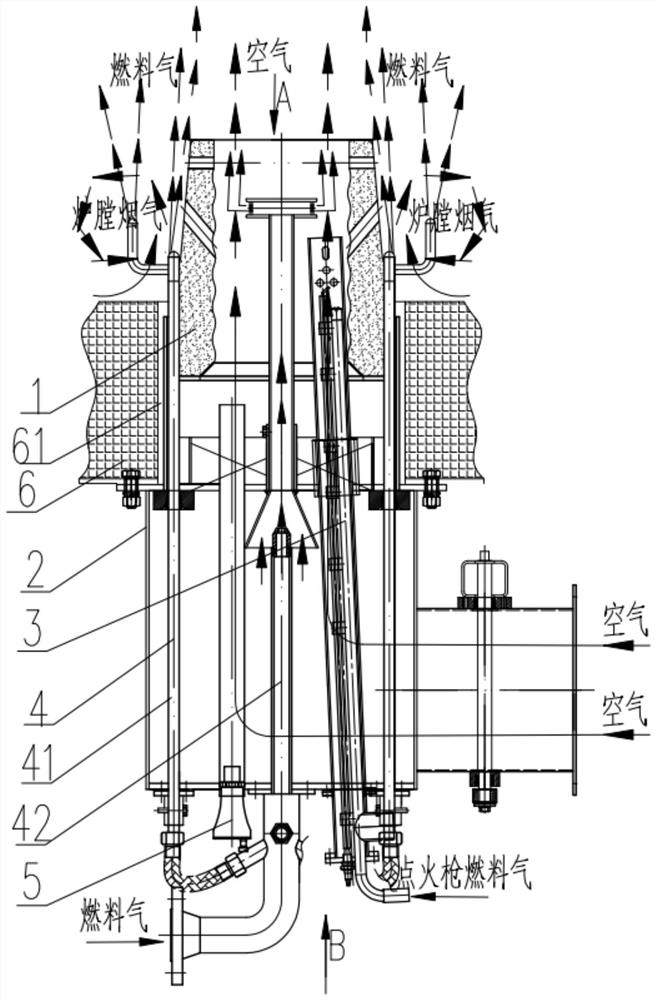

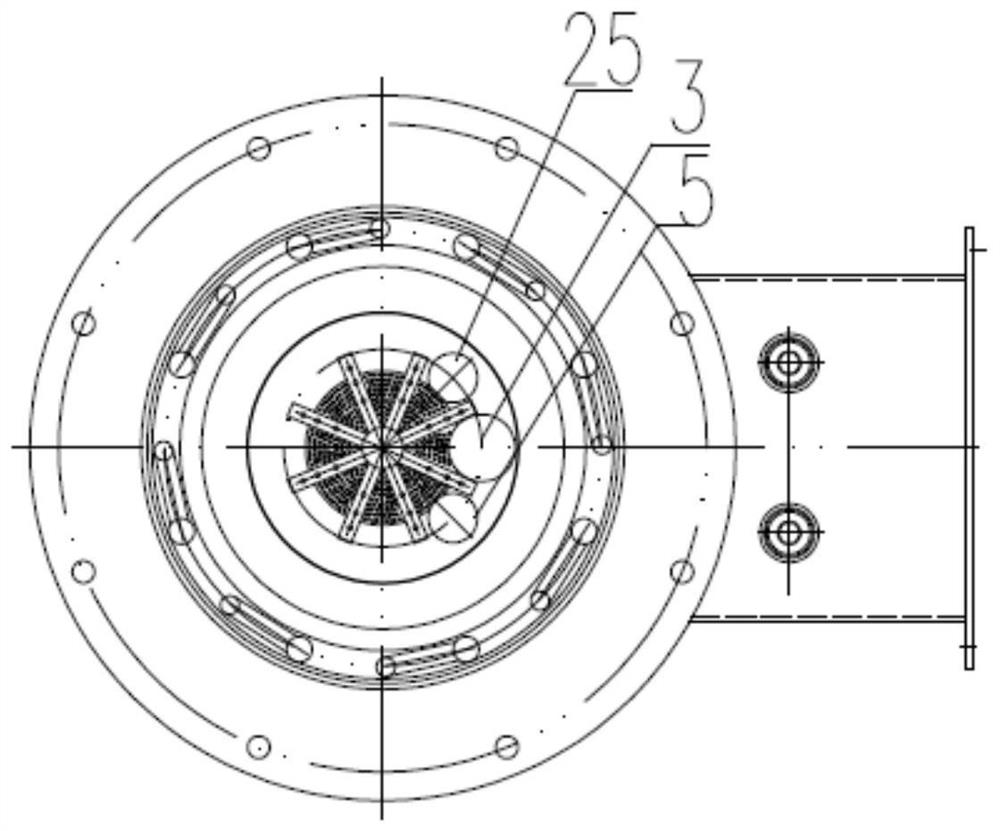

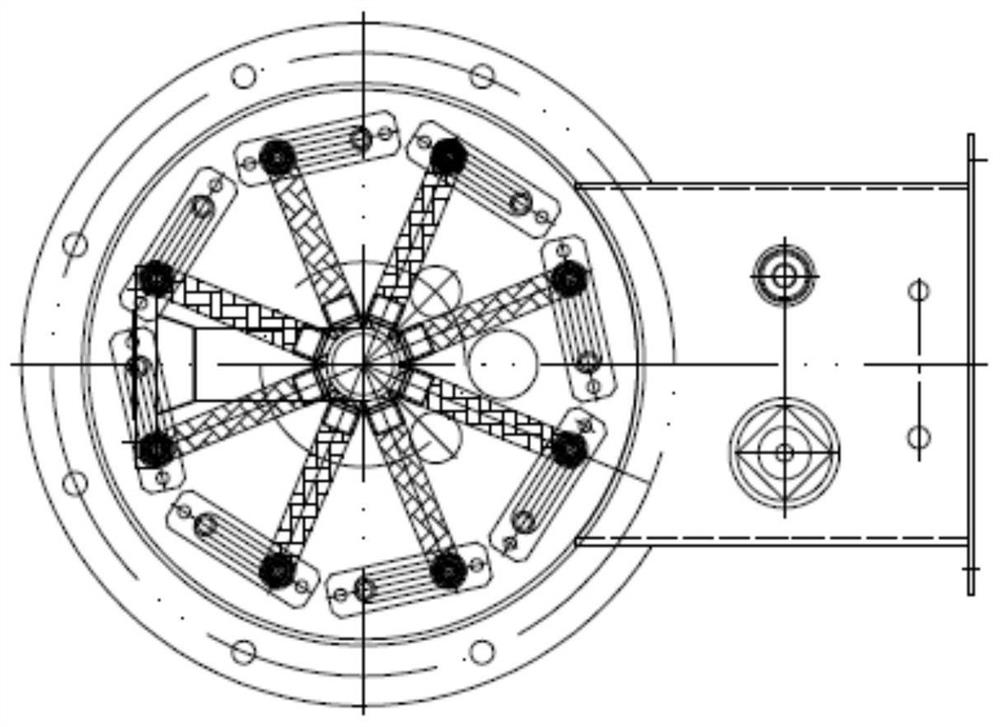

[0040] Such as Figure 1-11 As shown, the present invention discloses an ultra-low NOx and CO emission gas burner for medium and small boilers, comprising a brazier brick 1, a barrel assembly 2, an ignition gun assembly 3 and a gas gun assembly 4, and the brazier brick 1 is made of AL 2 o 3 >80% castables are poured through molds and pre-dried at 260°C. The brazier brick 1 is installed on one end of the cylinder assembly 2, and the other end of the cylinder assembly 2 is provided with a bottom plate 27 and an air regulating port 28, the bottom plate 27 is welded on the bottom of the cylinder assembly 2, and the air regulating port 28 is arranged on one side of the bottom of the cylinder assembly 2 On the side, a combustion-supporting air electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com