Cable joint lead sealing part pulsed eddy current detection device and application method thereof

A cable joint, pulsed eddy current technology, applied in measuring devices, material analysis by electromagnetic means, instruments, etc., can solve problems such as failure to achieve detection goals, and achieve the effect of improving detection sensitivity, strong sensitivity, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

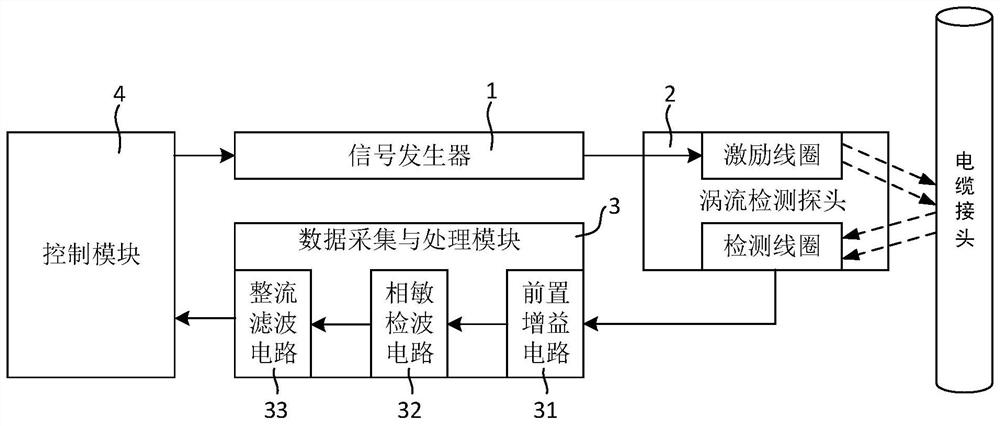

[0028] Such as figure 1 As shown, the pulsed eddy current detection device for the cable joint lead seal part of this embodiment includes a signal generator 1, an eddy current detection probe 2, a data acquisition and processing module 3 and a control module 4, and the control terminal of the signal generator 1 is connected to the control module 4. An excitation coil and a detection coil are provided in the eddy current detection probe 2 , the output end of the signal generator 1 is connected to the excitation coil, and the output end of the detection coil is connected to the control module 4 through the data acquisition and processing module 3 . The pulsed eddy current detection device for the lead seal part of the cable joint in this embodiment can realize the surface and near-surface defect detection of the lead seal part of the high-voltage cable joint, has high detection accuracy, sensitivity and strong anti-interference ability, and is small in size and easy to operate A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com