Intelligent mine data acquisition method based on 5G industrial Internet of Things

An industrial Internet of Things and data acquisition technology, applied in the direction of instruments, computer control, simulators, etc., can solve problems such as illegal operations, illegal command, complex natural conditions, etc., and achieve the effect of reducing safety hazards and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

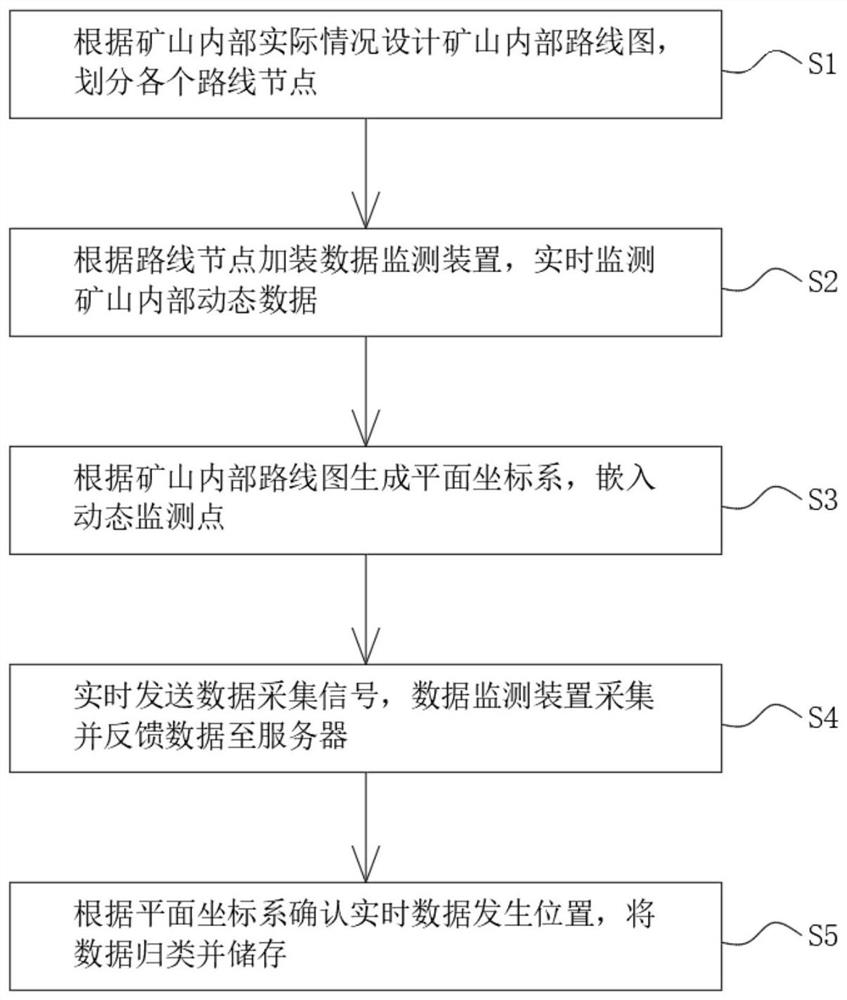

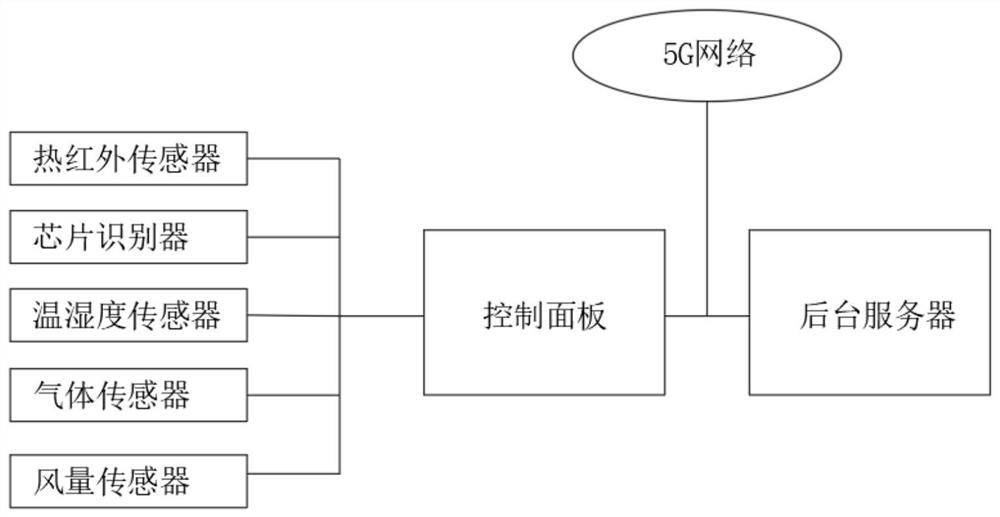

[0037] Such as Figure 1-2 As shown, the embodiment of the present invention provides a smart mine data collection method based on the 5G Industrial Internet of Things, and the data collection method includes the following steps:

[0038] S1. Design the internal route map of the mine according to the actual situation inside the mine, and divide each route node, as follows:

[0039] 1) The staff enter the mine to count the main roads and branch roads inside the mine, calculate the length, maximum and minimum width, and maximum and minimum height of each main road and branch road, and draw according to the scaling ratio through 3D drawing software to generate the inside of the mine 3D map of the route;

[0040] 2) Add route nodes in the three-dimensional map of the internal route of the mine according to the equidistant principle, and set a signal receiving device in each route node to receive signals from external 5G signal towers;

[0041] S2. Install data monitoring devices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com