Glass bottle inner opening grinding device and using method thereof

A glass bottle, inner mouth technology, applied in glass recycling, glass production, grinding machines, etc., can solve the problems of high grinding operation requirements, affecting grinding efficiency, uneven grinding, etc., to avoid uneven grinding, good versatility, lightening The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

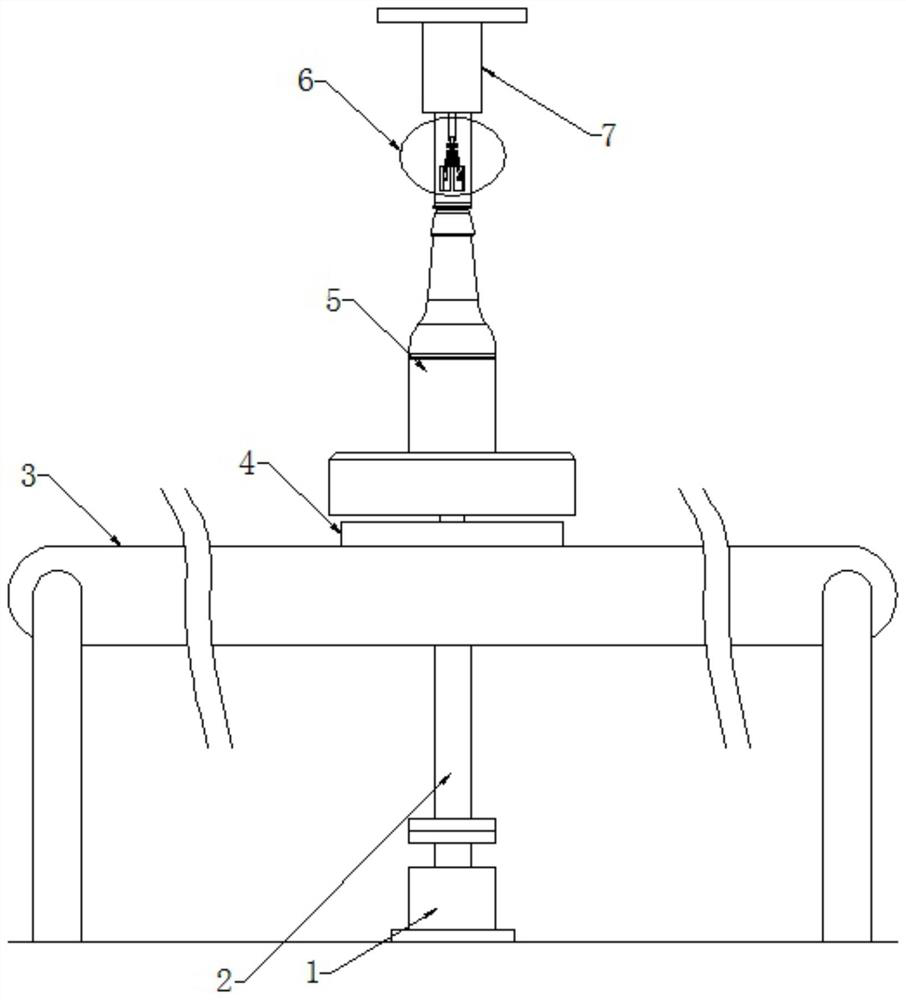

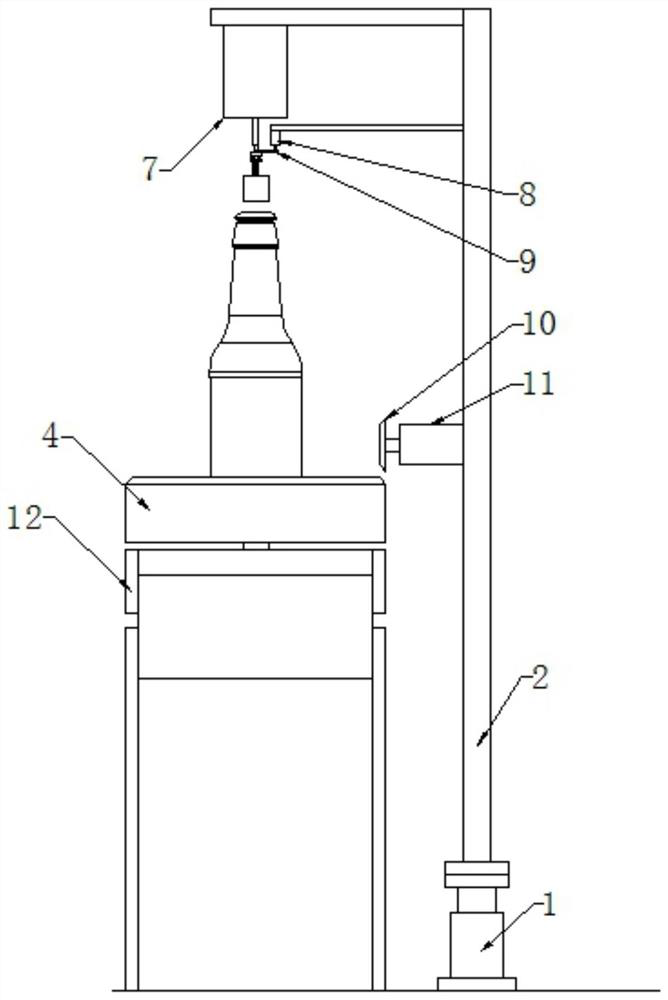

[0031] This embodiment proposes a glass bottle inner mouth grinding device, including a conveyor belt 3, guard plates 12 are provided on both sides of the conveyor belt 3, and a lifting cylinder 1 is fixedly connected to a support 2; the support 2 is provided with a grinding motor 7, press down cylinder 8 and rotary motor 11; Press down cylinder 8 is fixedly connected with lower pressing plate 9, and rotary motor 11 is fixedly connected with bevel gear I10, is provided with support mechanism 4 between guard plate 12 on conveyor belt 3; Grinding motor 7 connects There are grinding mechanism 6.

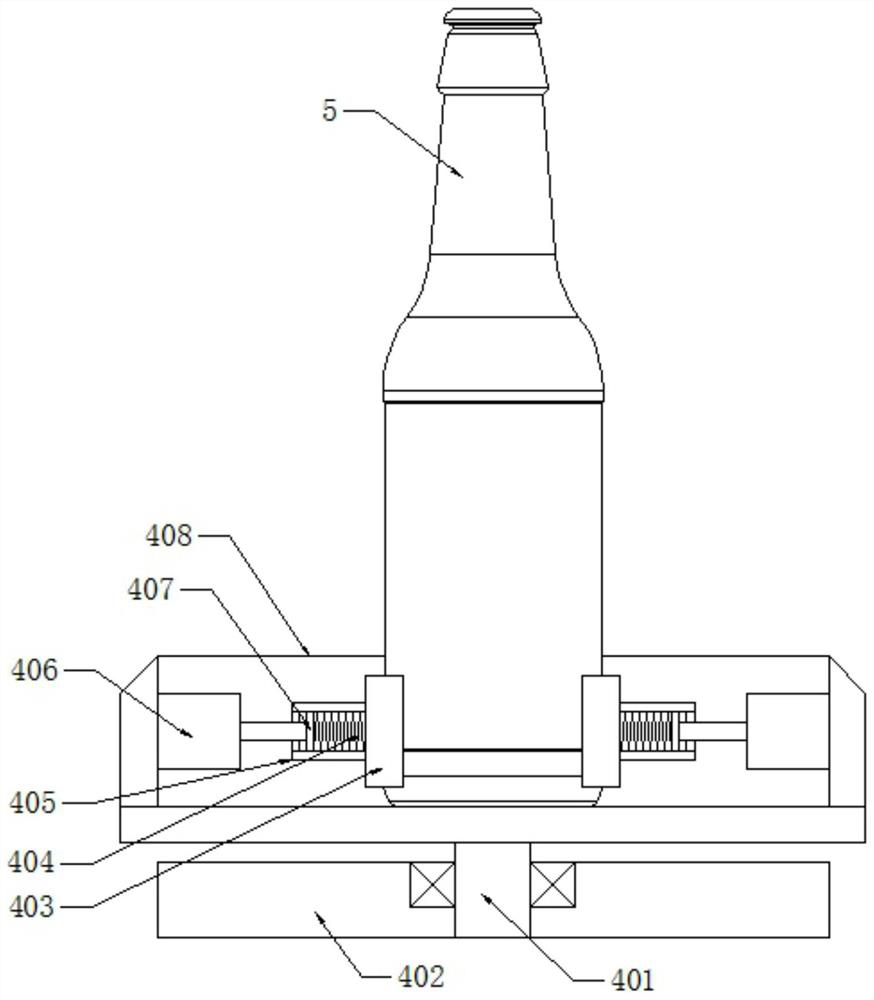

[0032] The support mechanism 4 includes a base 402, the base 402 is fixedly connected with a rotating shaft 401, and the other end of the rotating shaft 401 is fixedly connected with a bevel gear II408. A pair of push rod motors 406 are arranged in the bevel gear II408, and the push rod motor 406 is connected with a push plate 407. The other side of the push plate 407 is connected to a ...

Embodiment 2

[0043] This embodiment proposes a glass bottle inner mouth grinding device, which includes all the structures of the grinding device proposed in Embodiment 1, and also includes the following structures:

[0044] The end of the lower pressing plate 9 is provided with a protrusion.

[0045] A pair of limiting plates 405 are arranged on the clamping block 403 , and the distance between the limiting plates 405 is 5 mm longer than the length of the pushing plate 407 .

[0046] The usage method of this embodiment is the same as the usage method of a glass bottle inner mouth grinding device described in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com