Self-positioning vertically-stacked process tray and manufacturing method thereof

A technology of vertical stacking and manufacturing method, applied in the field of component assembly, which can solve the problems of large occupation area, easy deformation of pallets due to heat, material damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

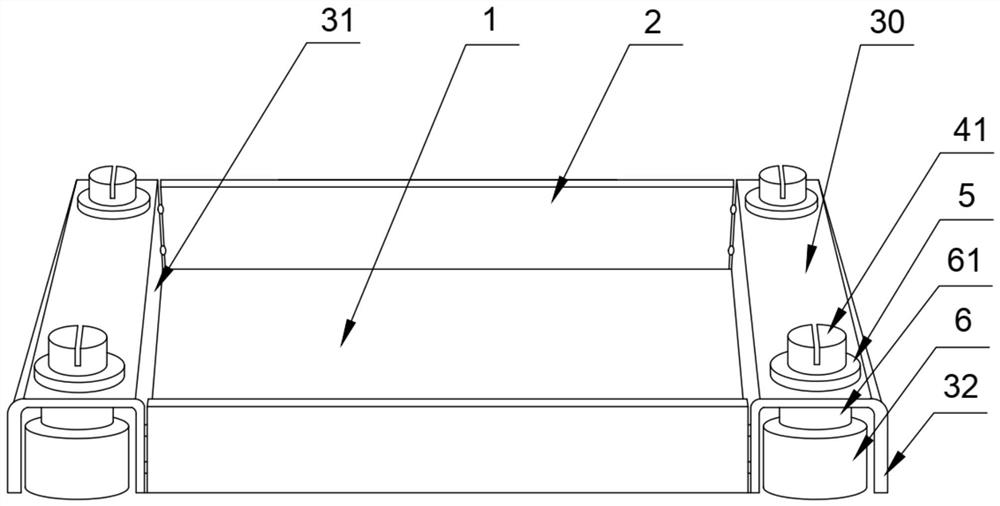

[0027] Such as figure 1 As shown, a preferred embodiment of the self-positioning vertically stacked process tray of the present invention includes a tray body and a positioning device, the tray body has a receiving groove for placing workpieces; the tray body preferably includes a rectangular bottom plate 1, the The two opposite sides of the base plate 1 are respectively provided with first baffles 2, and the other two opposite sides are respectively provided with second baffles, the second baffles are in an inverted "U" shape, including the first A vertical section 31 , a horizontal section 30 and a second vertical section 32 .

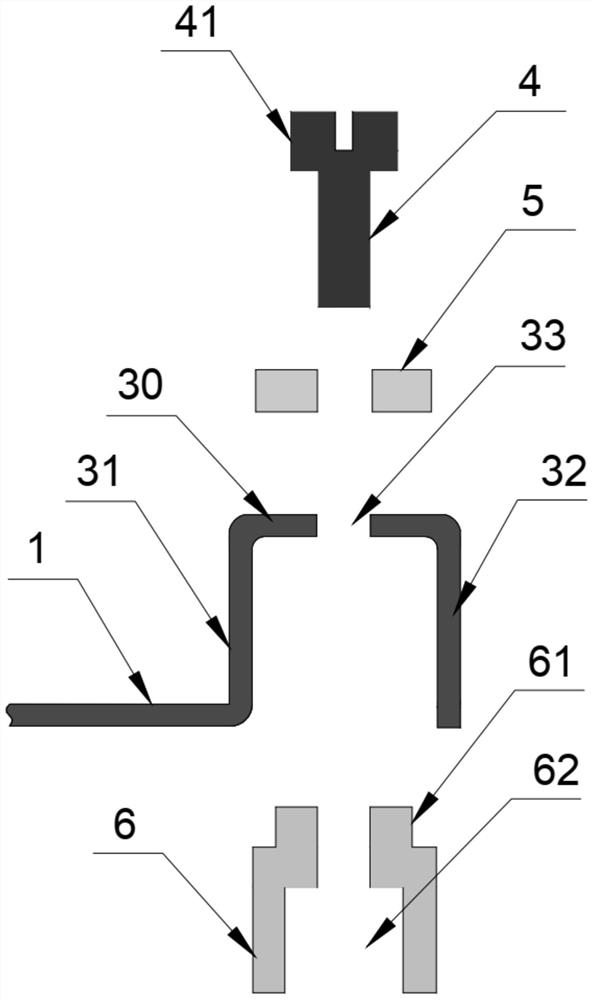

[0028] Such as figure 2 As shown, each of the two ends of the horizontal section 30 is respectively provided with a positioning device, and the positioning device includes a positioning rod 5, a gasket 51 and a positioning column 6; The positioning through hole 33, the upper end of the positioning rod 5 is provided with an anti-off part 4, and the...

Embodiment 2

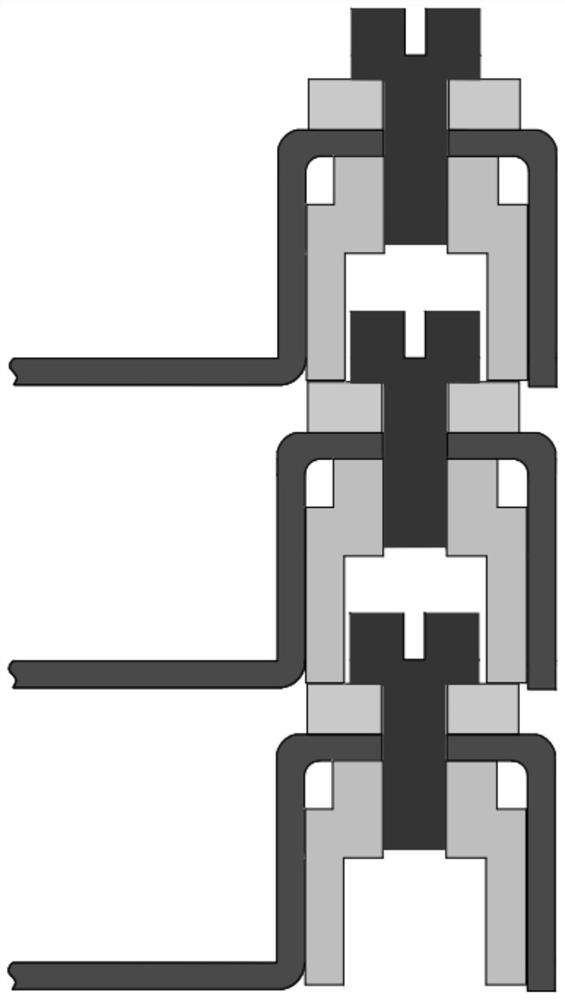

[0043] Such as Figure 4 As shown, another preferred embodiment of the self-positioning vertically stacked process tray of the present invention includes a tray body and a positioning device, the tray body has a receiving groove for placing workpieces; the tray body preferably includes a rectangular bottom plate 1, so The two opposite sides of the bottom plate 1 are respectively provided with a first baffle 2, and the other two opposite sides are respectively provided with a second baffle, and the second baffle is in an inverted "U" shape, including A first vertical section 31 , a horizontal section 30 and a second vertical section 32 .

[0044] Such as Figure 5 As shown, a positioning device is respectively provided at both ends of each said horizontal section 30, and said positioning device comprises an anti-off part 4, a positioning rod 5, a gasket 51 and a positioning post 6; said positioning rod 5 and positioning post 6 is made by one-piece molding, of course, the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com