Bearing housing for flow machine and flow machine with bearing housing

A technology for bearing shells and flow machines, applied in parts of pumping devices for elastic fluids, rigid supports for bearing parts, bearing cooling, etc., can solve problems such as high bearing shell cost, increased wear and tear, failure of bearings, etc. , to achieve the effect of extending the ambient temperature range, adequate lubrication and cooling, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

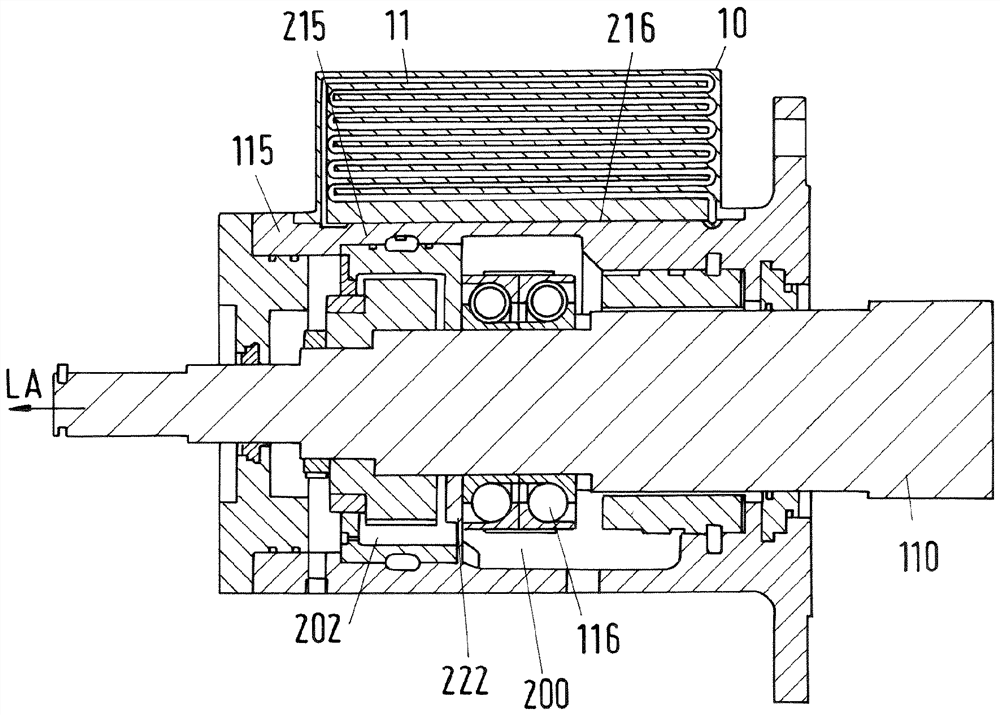

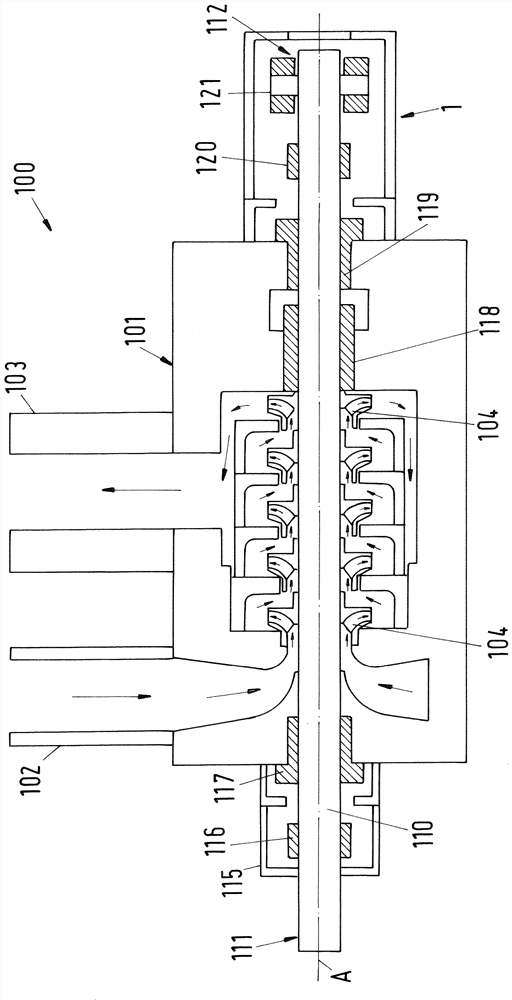

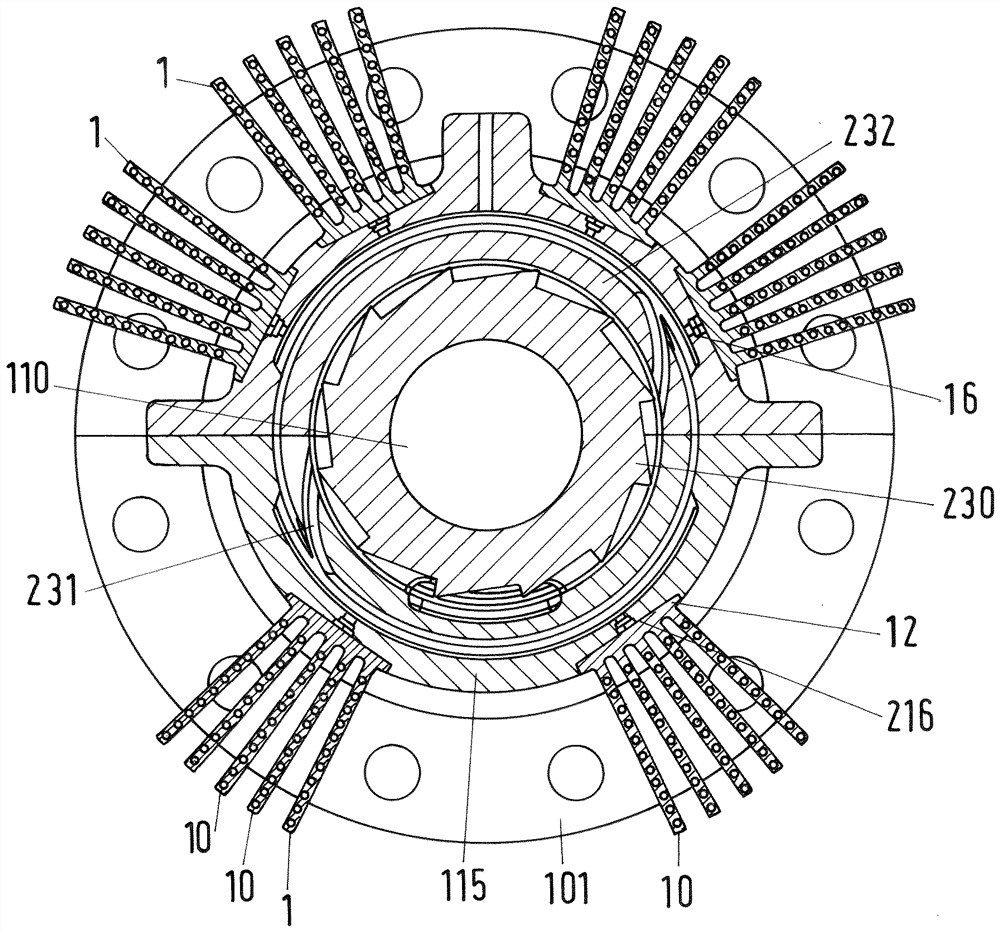

[0032] In the following description, reference is made by way of example to an important application, namely the flow machine is designed as a centrifugal pump.

[0033] figure 1 A cross-sectional view of an embodiment of a flow machine according to the invention is shown, designated as a whole by the reference numeral 100 . An example of a flow machine 100 is a centrifugal pump 100 for conveying fluids such as water or crude oil or multiphase liquids. Obviously, the present invention is neither limited to figure 1 The centrifugal pump 100 shown in , is also not limited to such a centrifugal pump, but rather refers to the flow machine 100 in general. For example, flow machine 100 could also be another type of pump, compressor, fan, expander, or turbine.

[0034] The centrifugal pump 100 comprises a housing 101 which may consist of a plurality of housing parts connected to each other to form the housing 101 . The housing 101 of the centrifugal pump 100 comprises an inlet 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com