A double-layer vibration isolator in the form of a hoop suitable for an underwater glider and its method

A technology of underwater glider and vibration isolator, which is applied to underwater ships, underwater operation equipment, instruments, etc., and can solve problems such as difficult to meet the needs of medium and low frequency vibration isolation, poor vibration isolation performance in medium and low frequency bands, and poor structural stability , to achieve good impact force, satisfy the light weight and reduce the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention.

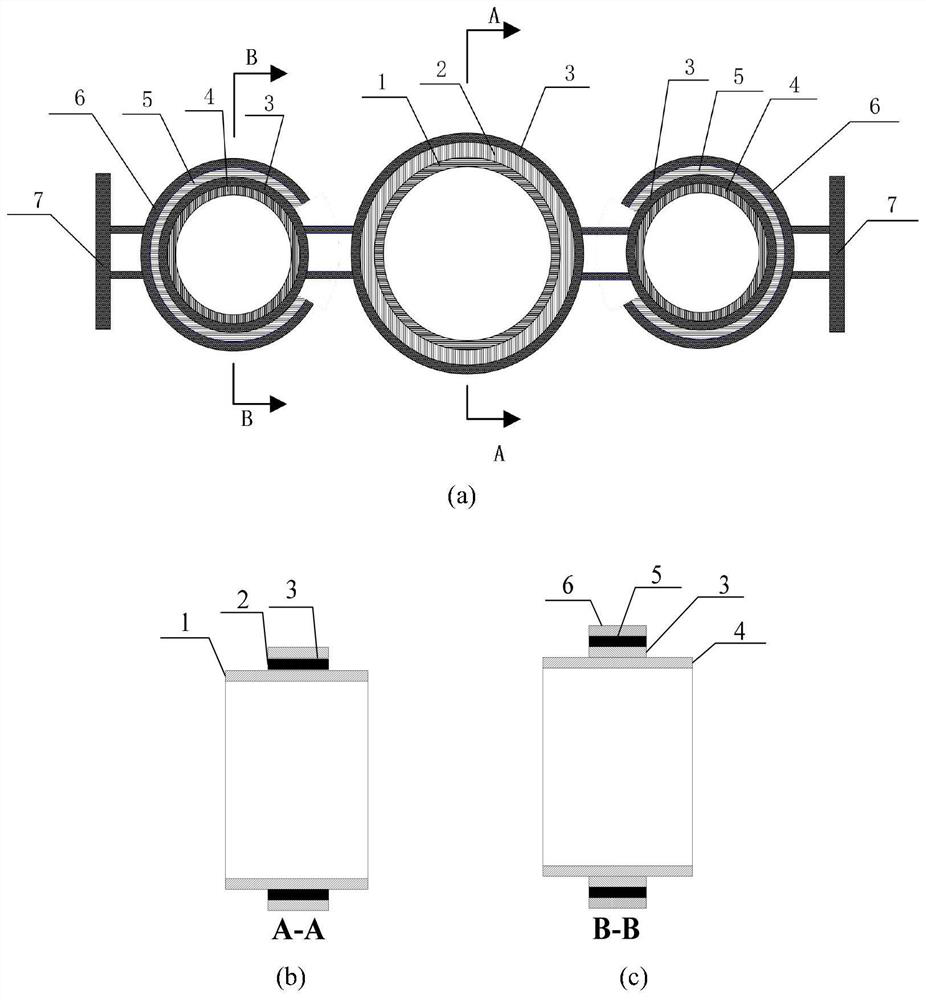

[0035] refer to figure 1 , which is a hoop-type double-layer rubber vibration isolator suitable for underwater gliders disclosed in the present invention, comprising a power unit cabin 1, a first layer of O-shaped rubber vibration isolators 2, a first layer of hoop 3, and a battery compartment. 4. The second layer of C-shaped rubber vibration isolation ring 5 , the second layer of C-shaped hoop 6 and the main wing frame 7 . The first layer of O-shaped rubber vibration isolation ring 2 is circular rubber, which is coaxially sleeved on the power unit cabin 1; the first layer of hoop 3 includes three rings and a first connecting beam, and the three rings are coaxial respectively It is sleeved on the outer peripheral surface of the first layer O-shaped rubber vibration iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com