Marble precision workbench air floatation jacking mechanism

A precision work, marble technology, applied in the direction of photomechanical equipment, pattern surface photoengraving process, photoengraving process exposure device, etc. The effect of reducing occupancy and increasing support height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

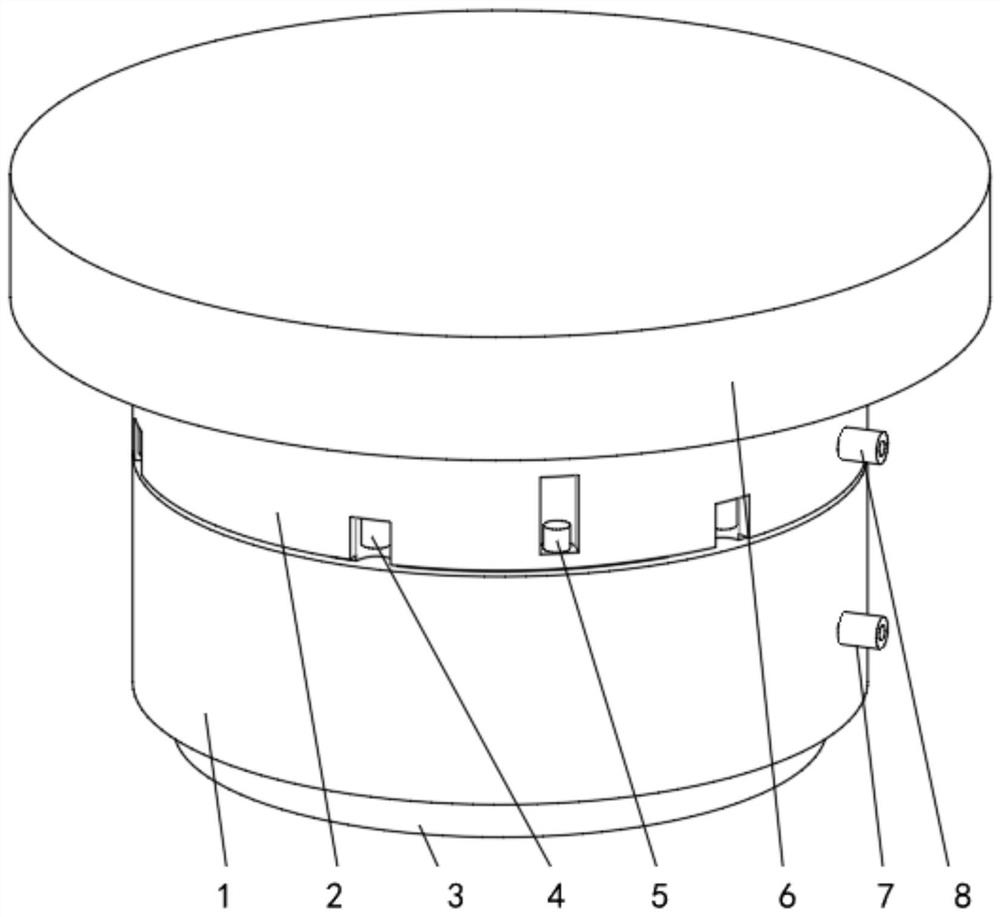

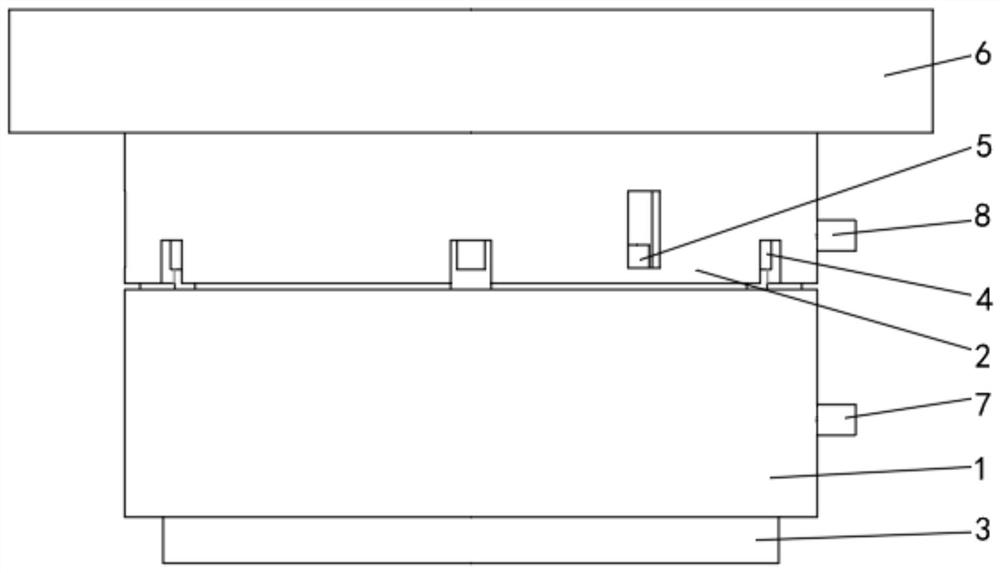

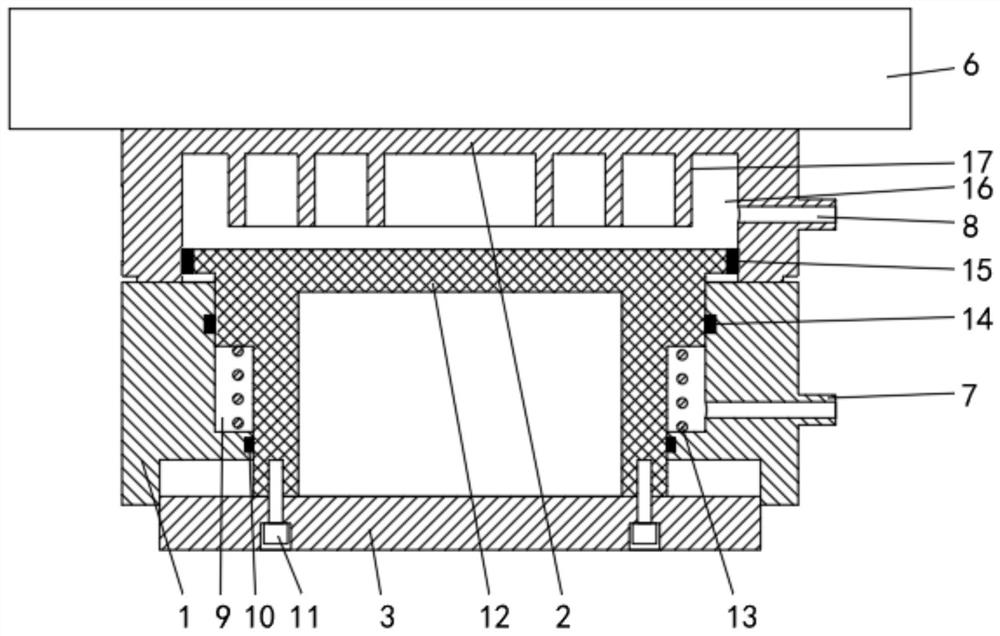

[0031] Such as Figure 1-4 As shown, the embodiment of the present invention provides a marble precision workbench air flotation jacking mechanism, including a cylinder body 1, the cylinder body 1 is a cylinder, the upper end of the cylinder body 1 is fixedly connected with a top cover 2, and the section of the corresponding top cover 2 is Round, the upper end of the top cover 2 is fixedly connected with a marble platform 6. For the convenience of display, the marble platform 6 here is a cylinder. The platform 6 can be installed according to actual needs. The piston 12 is fixedly connected to the inside of the cylinder body 1. The piston 12 is a three-stage stepped cylindrical shape, and the interior is hollow, which can reduce the overall mass of the piston 12 and facilitate For transfer use, the lower end of the piston 12 is fixedly connected with the air-floating cushion 3, the lower end surface of the air-floating cushion 3 is in contact with the supporting parts, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com