Auxiliary equipment maintenance system and method

A technology for auxiliary equipment and maintenance personnel, applied in the fields of instruments, data processing applications, forecasting, etc., can solve the problems of long time to determine the cause of failure, allocation of maintenance personnel, waste of time, etc., to shorten the maintenance time, improve maintenance efficiency, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

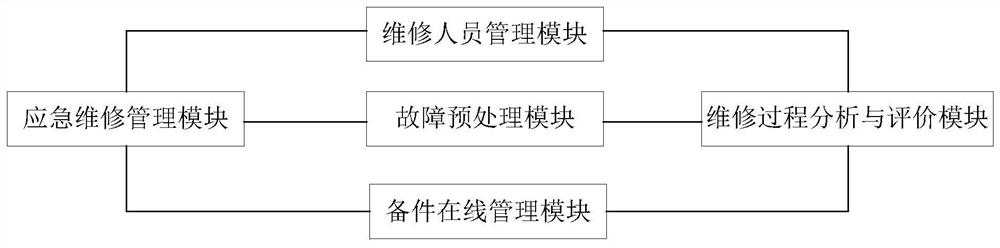

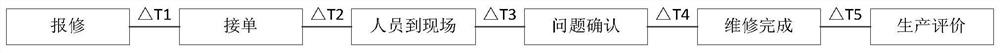

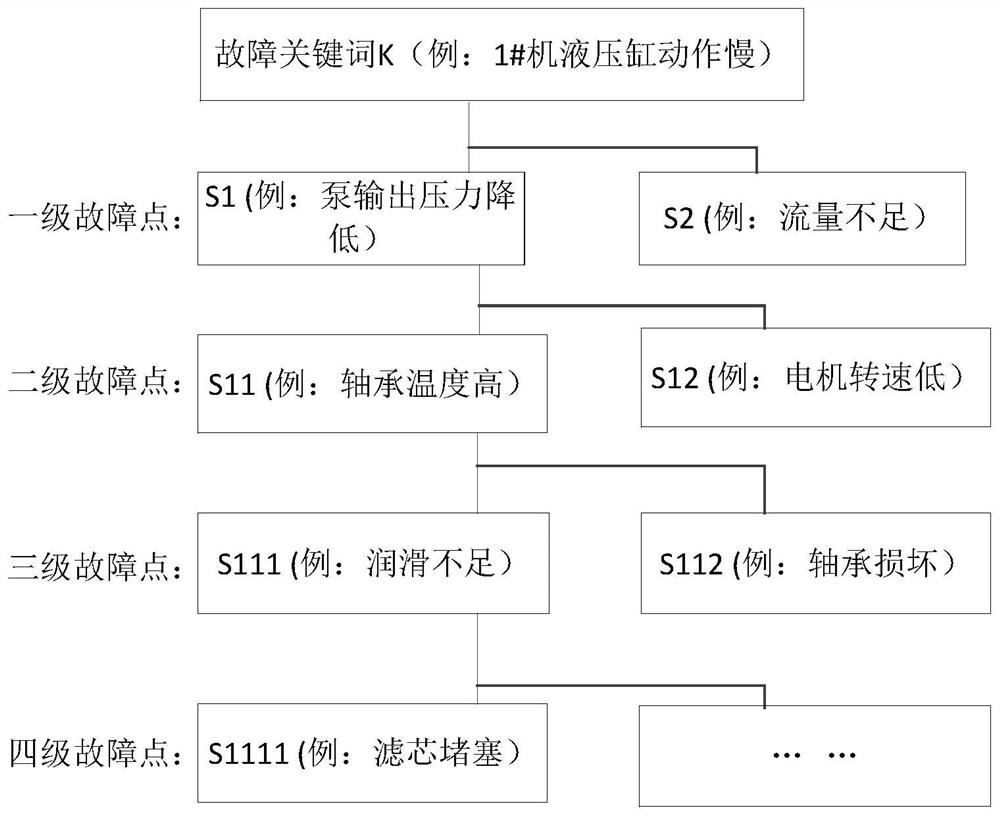

[0049] Example: such as figure 1 As shown, a system for auxiliary equipment maintenance includes an emergency maintenance management module, a maintenance personnel management module, a fault pretreatment module, an online spare parts management module, and a maintenance process analysis and evaluation module. The emergency maintenance management module is used to record the fault process time; The maintenance personnel management module is used to count the status of the current maintenance personnel, real-time statistics of the attendance of the maintenance personnel in the current maintenance team, and the current working conditions of the maintenance personnel. When assigning maintenance work tasks, the team can combine the current idle status of maintenance personnel to realize the precise assignment of tasks. At the same time, the maintenance personnel management module can count maintenance personnel's specialties, current maintenance levels, and historical faulty equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com