Full-automatic net blocking/dismounting telescopic crossing frame

A telescopic, spanning frame technology, applied in the field of spanning frames, can solve the problems that the sealing arm cannot meet the impact resistance performance of the telescopic spanning frame, the hydraulic cylinder pressure is not adjusted well, and the speed of sealing/disassembling the net is slow. The effect of high-altitude fall risk, low overall quality, and safety risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

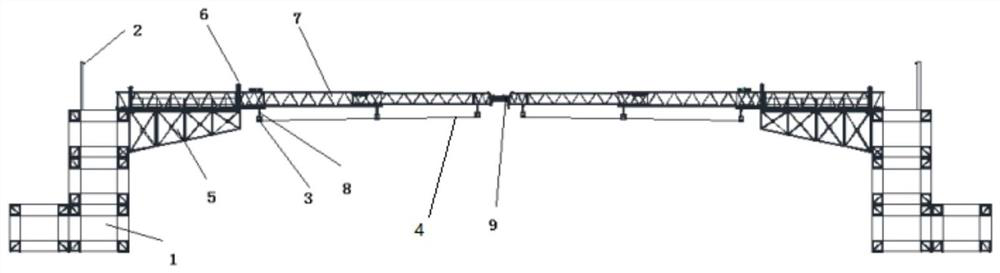

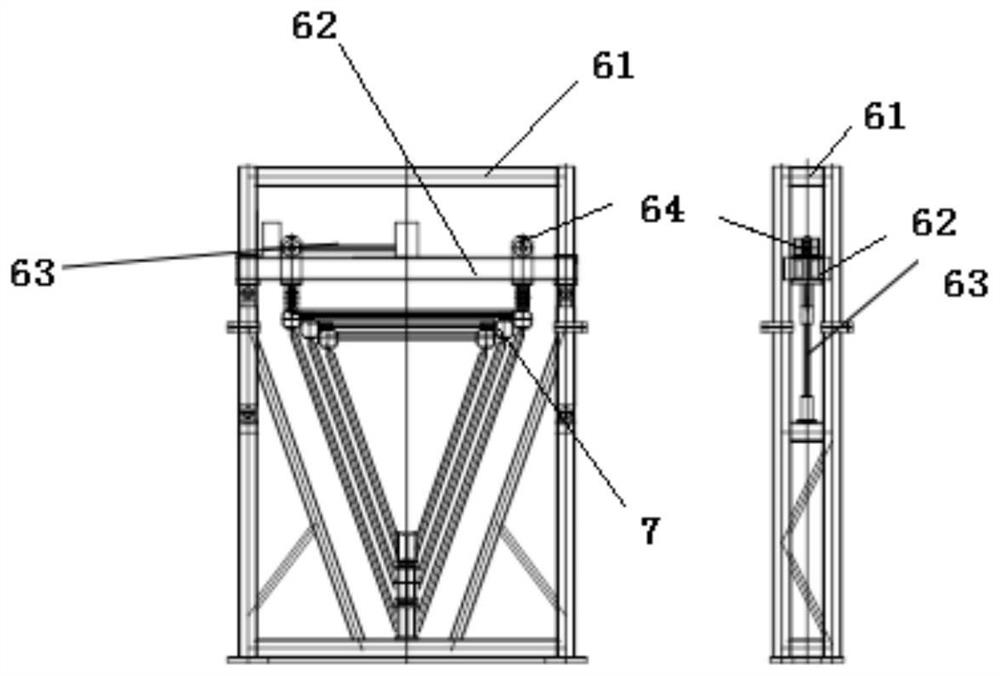

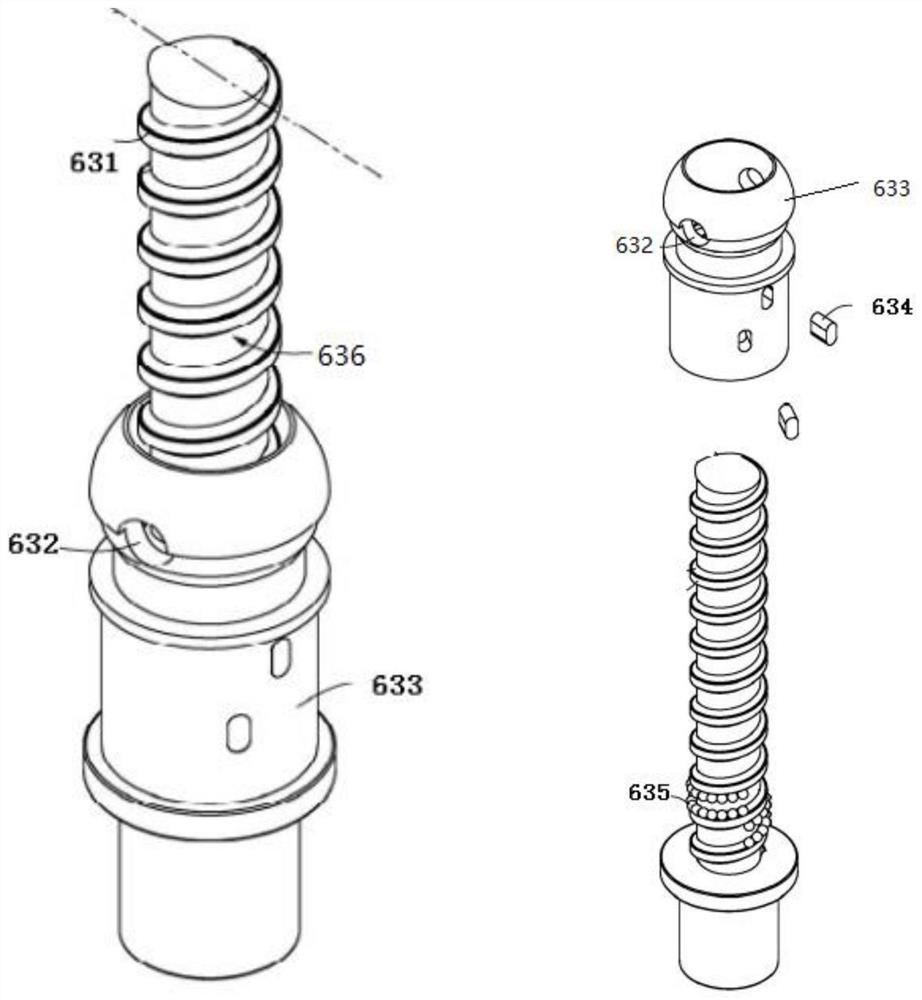

[0037] Such as figure 1 As shown, a fully automatic net closing / unnetting retractable spanning frame provided in this embodiment includes two frame bodies 1, two spanning components arranged between the two frame bodies 1 and parallel to each other, Hard-sealed net holding poles 3 and insulating nets between the components; the spanning component includes two mutually symmetrical spanning units, the spanning unit includes a working platform 5 connected to the outside of the frame body 1, an adjustment bracket 6 arranged on the upper side of the working platform 5, The telescopic net sealing boom 7 that penetrates through the adjustment bracket 6 and is connected with it, the docking mechanism 9 provided at the front end of the net sealing boom 7 and the anti-twist mechanism 8 provided at the lower side of the net sealing boom 7, and the hard sealing net holding rod 3 is connected with the anti-twist mechanism 8, and the hard-sealing net holding rod 3 is axially perpendicular t...

Embodiment 2

[0044] The net-sealing arm 7 of the telescopic spanning frame provided in this embodiment includes the following components by mass percentage: C0.2%, Si 0.55%, Mn 1.0%, P 0.035%, S 0.03%, Cr 0.3% , Ni 0.1%, Cu 0.4%, and the balance is iron and impurities.

[0045] Butt joints include the following components by mass percentage: C 1.0%, Si 0.85%, Mn 1.3%, Cr 7.2%, Ni 0.85%, Mo 0.55%, Ti 0.25%, P0.05%, the balance For iron and impurities.

Embodiment 3

[0047] The net-sealing arm 7 of the telescopic spanning frame provided in this embodiment includes the following components by mass percentage: C0.24%, Si 0.4%, Mn 1.6%, P 0.03%, S 0.035%, Cr 0.2% , Ni 0.35%, Cu 0.2%, and the balance is iron and impurities.

[0048] Butt joints include the following components by mass percentage: C 1.9%, Si 0.7%, Mn2.3%, Cr8.5%, Ni 0.6%, Mo 0.7%, Ti 0.15%, P0.07%, the balance For iron and impurities.

[0049] Adopting the material of the net-sealing arm 7 provided by the present invention effectively improves its impact resistance, and the material of the butt joint effectively improves its strength, both of which improve the service life of the spanning frame, and are suitable for engineering applications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com