Mems packaging structure and preparation method of mems packaging structure

A packaging structure and packaging circuit board technology, which is applied in the direction of sensors, electrical components, semiconductor electrostatic transducers, etc., can solve the problems of sensitivity and signal-to-noise ratio reduction, unfavorable product miniaturization, and large packaging size, etc., to improve sensitivity and Signal-to-noise ratio, small package size, and performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

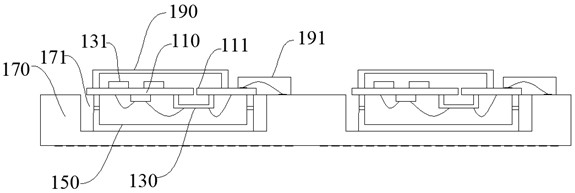

[0044] see figure 1 , the present invention provides a MEMS packaging structure 100, which can reduce the packaging size of silicon wheat products, is conducive to the miniaturization of silicon wheat products, and can realize the improvement of sensitivity and signal-to-noise ratio at the same time, so as to improve product performance, and can avoid When the sound pressure changes greatly, it will cause the rupture of the silicon diaphragm and play a good role in protecting the wiring structure.

[0045] The MEMS packaging structure 100 provided in this embodiment includes an integrated circuit board 110, a MEMS chip 130, a first cavity cover 150, a packaging circuit board 170 and a second cavity cover 190, and the MEMS chip 130 is mounted on the lower side of the integrated circuit board 110, The first cavity cover 150 is also mounted on the lower side of the integrated circuit board 110 and is covered outside the MEMS chip 130. The package circuit board 170 is provided wit...

no. 2 example

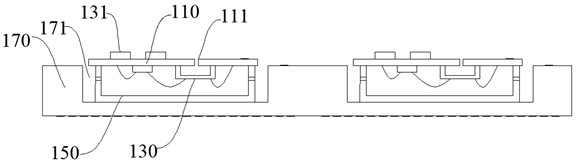

[0064] see figure 2 , this embodiment provides a MEMS package structure 100, its basic structure and principle and the technical effects produced are the same as those of the first embodiment, for a brief description, the parts not mentioned in this embodiment can refer to the first embodiment corresponding content. The difference between this embodiment and the first embodiment lies in the structure of the third chamber cover 191 .

[0065]In this embodiment, the MEMS package structure 100 includes an integrated circuit board 110, a MEMS chip 130, a first cavity cover 150, a packaging circuit board 170 and a second cavity cover 190, and the MEMS chip 130 is mounted on the lower side of the integrated circuit board 110, The first cavity cover 150 is also mounted on the lower side of the integrated circuit board 110 and is covered outside the MEMS chip 130. The package circuit board 170 is provided with a sound inlet accommodation groove 171, and the first cavity cover 150 is...

no. 3 example

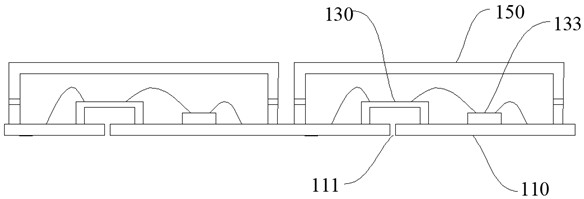

[0072] see image 3 , this embodiment provides a MEMS package structure 100, its basic structure and principle and the technical effects produced are the same as those of the first embodiment, for a brief description, the parts not mentioned in this embodiment can refer to the first embodiment corresponding content. Different from the first embodiment, in this embodiment, an adhesive layer is used to replace the third cavity cover 191 .

[0073] The MEMS packaging structure 100 includes an integrated circuit board 110, a MEMS chip 130, a first cavity cover 150, a packaging circuit board 170 and a second cavity cover 190, the MEMS chip 130 is mounted on the lower side of the integrated circuit board 110, and the first cavity cover 150 is also Mounted on the lower side of the integrated circuit board 110 and covered outside the MEMS chip 130, the packaging circuit board 170 is provided with a sound inlet accommodation groove 171, the first chamber cover 150 is correspondingly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com