An integrated temperature-controlled battery pack

A battery pack, all-in-one technology, applied in secondary batteries, battery/fuel cell control devices, circuits, etc., can solve the problems of large temperature control fluctuations, slow response to temperature changes, and long heat exchange process, and achieve temperature control. The effect of small fluctuation, improved response speed, and accelerated thermal balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

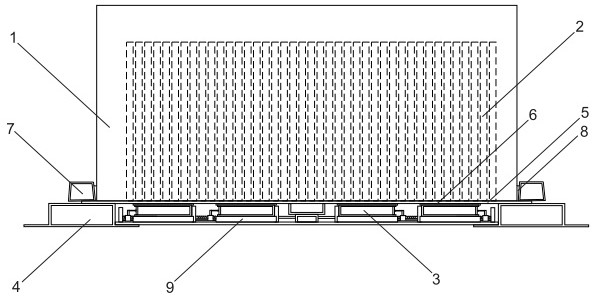

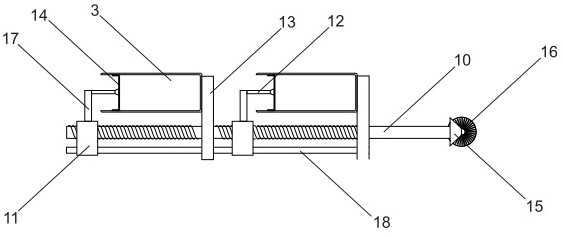

[0022] like figure 1 , figure 2 As shown, an integrated temperature-controlled battery pack includes a box 1 and a battery module 2. The battery module 2 is fixed in the box 1, and the bottom of the box 1 is provided with a liquid for cooling the battery module 2. The cooling pipe 3 and the liquid cooling pipe 3 circulate a cooling liquid, and the cooling liquid is water. The liquid cooling pipe 3 is connected with the flow channel width adjustment mechanism. The cross section of the liquid cooling pipe 3 is rectangular, the liquid cooling pipe 3 is a straight pipe, each box 1 is equipped with four liquid cooling pipes 3 and all the liquid cooling pipes 3 are parallel, and both ends of the liquid cooling pipes 3 are connected to a common liquid collector The two common liquid collecting pipes are the liquid inlet liquid collecting pipe and the liquid discharging liquid collecting pipe respectively. The liquid inlet liquid collecting pipe is connected to a pressurizing pump...

Embodiment 2

[0025] The heat-conducting layer 6 is formed by pouring and curing the heat-conducting structural glue. The rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com