Printing method for composite plastic flexible package

A technology for compounding plastics and printing methods, applied in chemical instruments and methods, laminating devices, devices for coating liquids on surfaces, etc. and other problems to achieve the effect of improving the effect of gluing, improving the efficiency of gluing, and improving the quality of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described below with reference to the drawings. In the process, in order to ensure the clarity and convenience of illustration, we may exaggerate the width of the lines or the size of the constituent elements in the diagram.

[0038] In addition, the following terms are defined based on the functions in the present invention, and may be different according to the user's or operator's intention or practice. Therefore, these terms are defined based on the entire content of this specification.

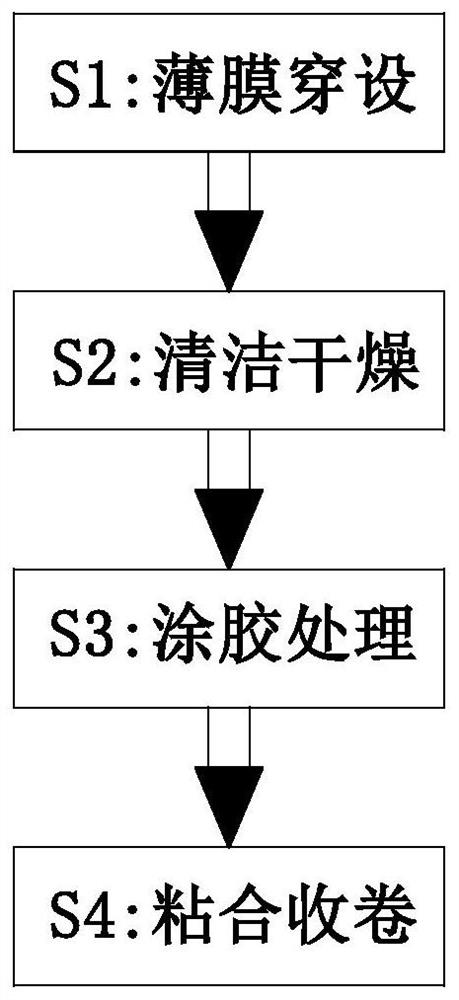

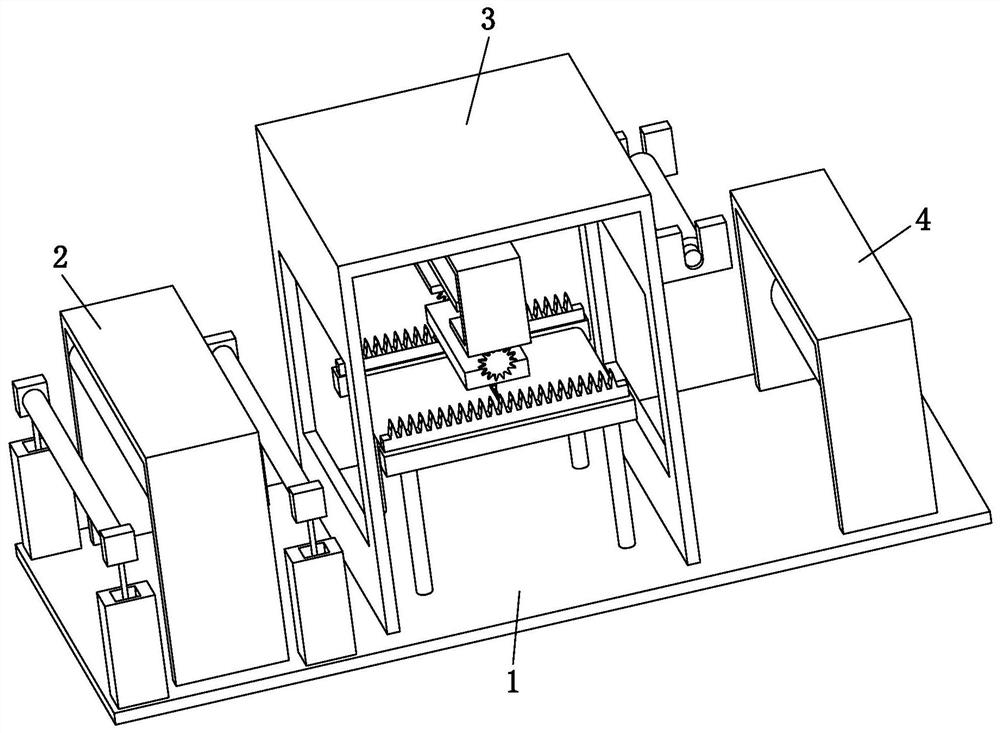

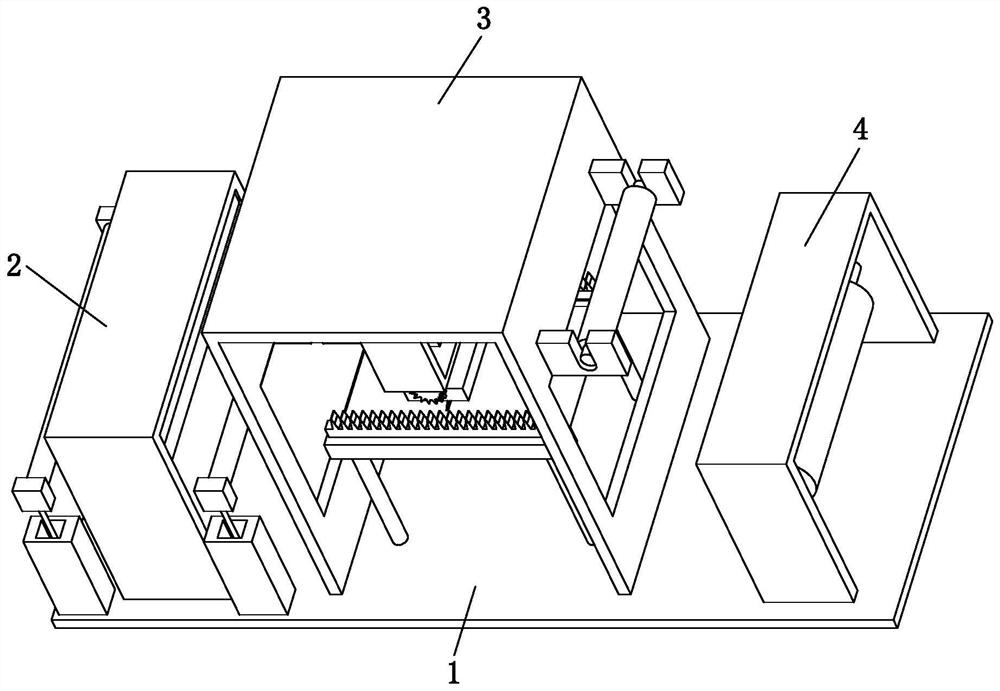

[0039] Such as Figure 1 to Figure 9 As shown, a composite plastic flexible packaging printing method, which uses a composite plastic flexible packaging printing equipment, the composite plastic flexible packaging printing equipment includes a bottom plate 1, a cleaning device 2, a gluing device 3 and a bonding and winding device 4, using the above The specific method of processing plastic film by composite plastic flexible packaging p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com