Multistage screening device for purifying terrazzo quartz sand and working method of multistage screening device

A screening device and quartz sand technology, which is applied in the field of quartz sand purification, can solve the problems of poor purification effect, inability to remove impurities, and insufficient screening of quartz sand, so as to achieve the effect of improving the purification degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

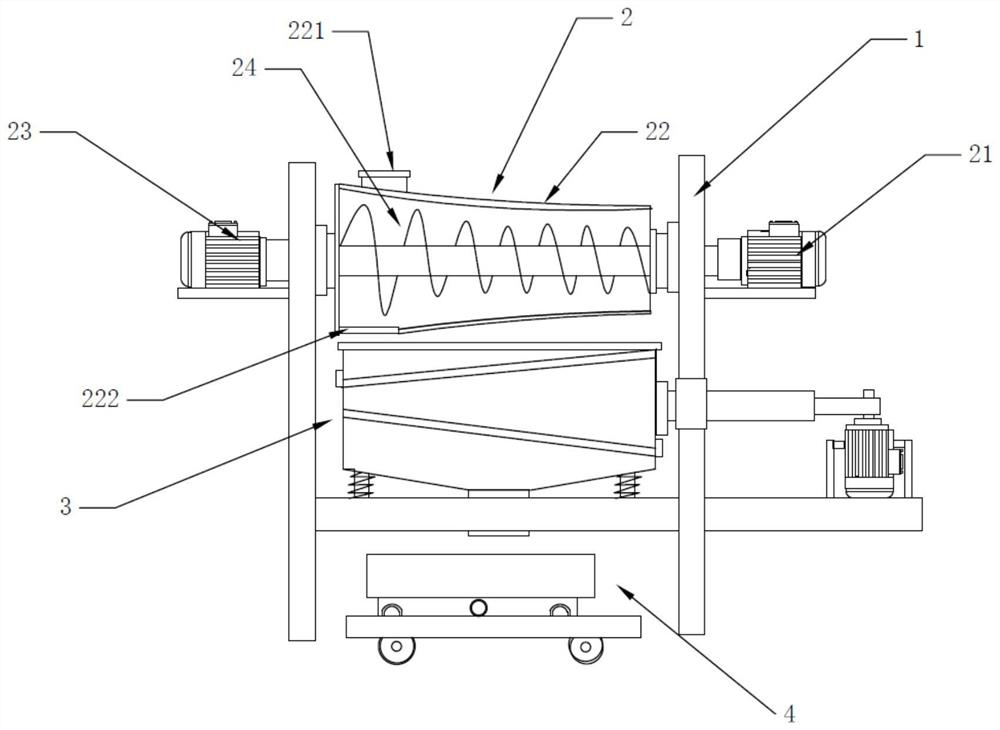

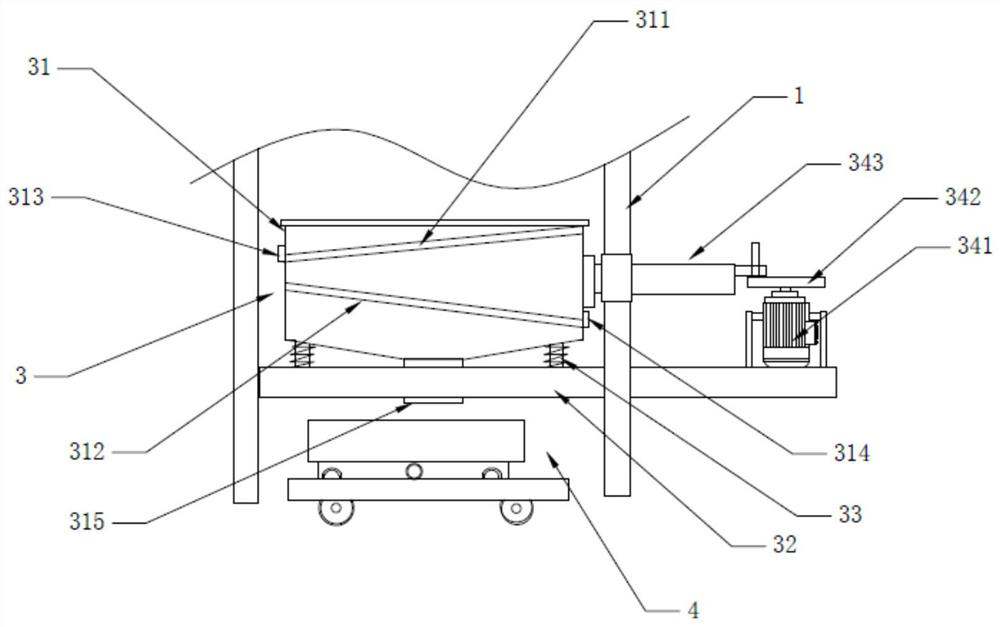

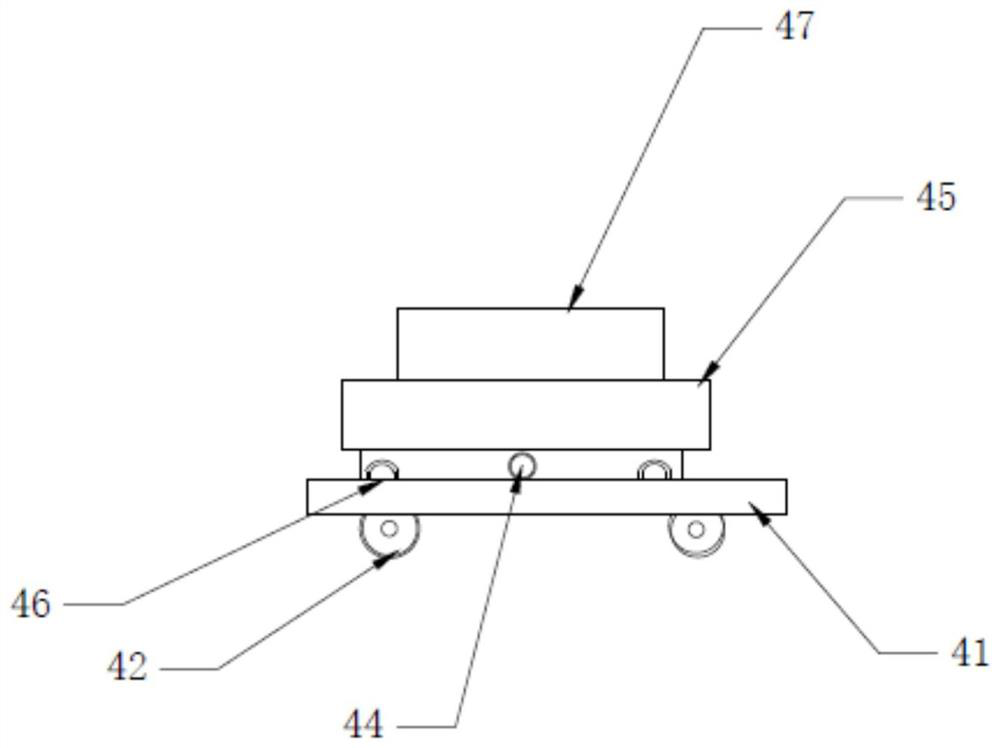

[0034] Such as Figure 1-4 Shown is a multi-stage screening device for the purification of terrazzo sand, which includes a branch

[0035] A frame 1, a rolling screening device 2, a swing screening device 3 and a material receiving device 4, the rolling screening device 2 is located on the upper side of the support 1, and the swing screening device 3 is located on the lower side of the rolling screening device 2.

[0036] Wherein, the rolling screening device 2 comprises a driving motor one 21, a screening drum 22, a driving motor two 23 and a spiral fin 24, and the driving motor one 21 and the driving motor two 23 are installed on both sides of the support 1, and the screening drum 22 It is arranged on the inner side of the support 1, and the helical fins 24 are arranged inside the screening drum 22. The drive shaft of the first driving motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com