Drill bit connecting structure of fixed-handle drill

A connection structure and drill bit technology, applied in drilling/drilling equipment, drill repair, drilling tool accessories, etc., can solve the problems of different chucks, affecting work efficiency, loosening, etc., to achieve simple and convenient assembly operation, stable and reliable connection , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. The embodiments are only used to explain the present invention and do not limit the protection scope of the present invention.

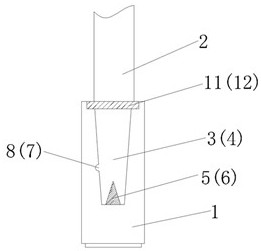

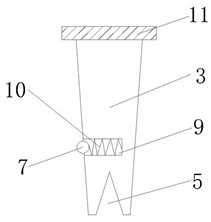

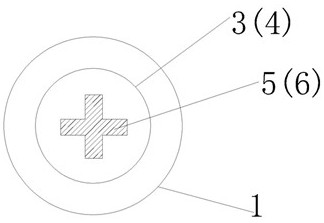

[0021] As shown in the figure, the present invention provides a fixed-shank drill bit connection structure, which adopts a fixed-shank design, including a drill shank 1 with a fixed diameter and a drill body 2 with different diameters, and the diameter of the drill shank is uniformly 12.7 mm, drill shank 1 and drill body 2 are made of cobalt-containing high-performance high-speed steel, which has higher hardness than ordinary high-speed steel, higher red hardness, more wear-resistant, longer life, and adopts full grinding production process , The precision of the product is higher, and the surface is coated with PDV, which further improves its wear resistance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com