Adjustable face-and-side cutter head and adjusting method

A technology of three-sided edge and milling cutter disc, which is applied in the field of mechanical processing, can solve the problems that are not conducive to ensuring the processing accuracy of products, is not conducive to production efficiency, and increases the cost of cutting tools, so as to save processing time, maximize efficiency, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

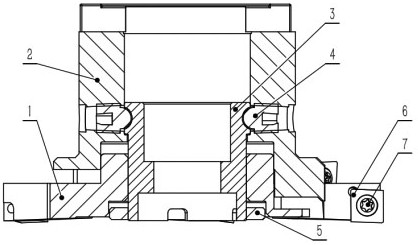

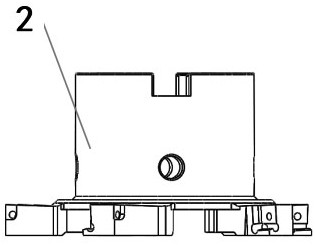

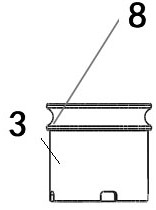

[0030] Embodiment 1: In combination with all the drawings; the adjustable three-sided edge milling cutter head is characterized in that the three-sided edge milling cutter head includes a fixed cutter head (2), and the fixed cutter head (2) contains a limit hole, which can also be limited The position locking screw (4) is pressed against the adjusting mandrel (3). The adjusting mandrel (3) contains a circle of arc-shaped grooves. The arc at the end of the limit locking screw (4) can fit the arc Groove, the adjustment mandrel can only rotate and cannot move up and down; the adjustable cutter head (1) is installed on the thread under the adjustment mandrel (3), and the relative position of the adjustable cutter head (1) can be adjusted by turning the adjustment mandrel (3) height; the lock nut (5) is ring-shaped, and the lock nut (5) is installed under the adjustment mandrel (3) to relatively lock the adjustable cutter head (1). The substantive technical effect and the realizati...

Embodiment 2

[0033] Embodiment 2: As a further improved solution or a side-by-side solution or an optional independent solution, the fixed cutterhead and the adjustable cutterhead adopt a structure in which the cutter position mounting surfaces are dislocated to achieve adjustment space. The substantive technical effect and the realization process of the technical solution here are as follows: the dislocation makes the adjustment convenient, and at the same time, the distribution is uniform.

Embodiment 3

[0034] Embodiment 3: As a further improved solution or a side-by-side solution or an optional independent solution, the knife position mounting surfaces of the fixed cutter head and the adjustable cutter head are each equipped with a blade (6) through a blade locking screw (7). The substantive technical effects and the realization process of the technical solution here are as follows: this embodiment provides a specific structure for fixing the blade, and similar realization structures are all within the scope of protection of this patent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com