High-voltage silicon stack alloy processing device and alloying method

A processing device, high-pressure silicon stacking technology, applied in metal processing equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of scrapped alloy workpieces, unstable pressure, large loss of raw materials, etc., to achieve uniform thickness and regularity, down pressure The action is smooth and gentle, and the effect of improving the strength of the solder tab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

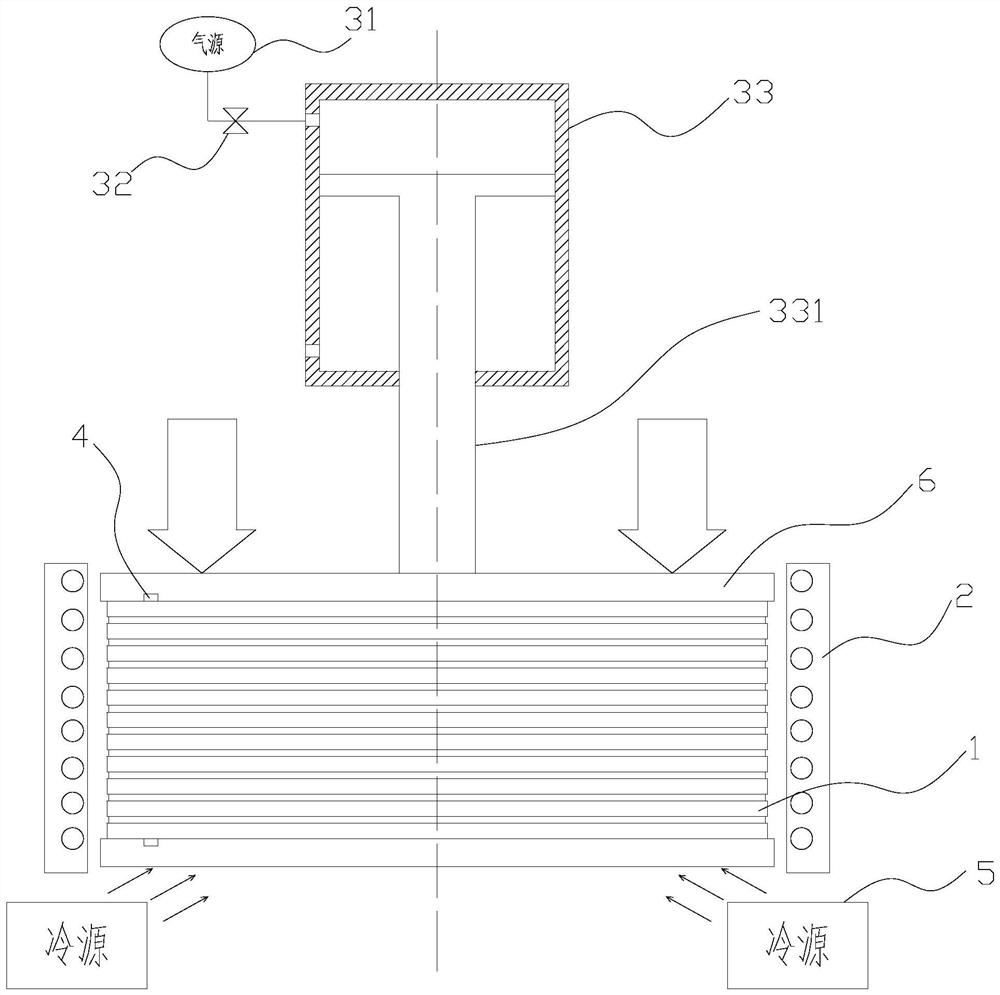

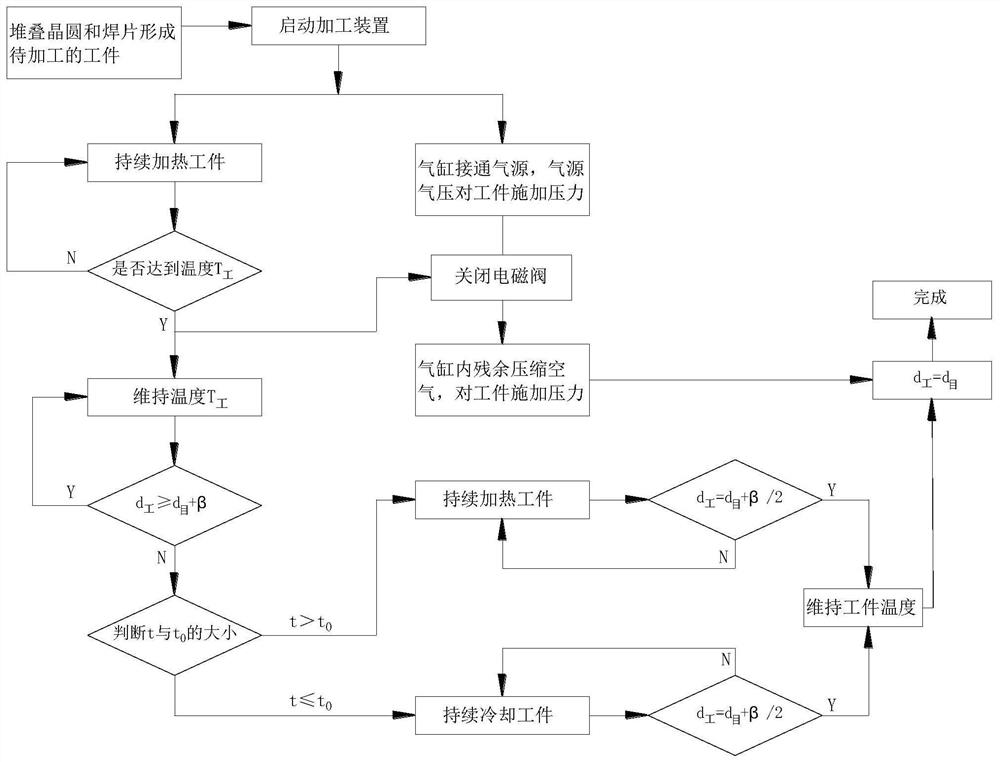

[0031] The following is attached Figure 1-2 , to further illustrate the present invention.

[0032] A high-pressure silicon stack alloy processing device of the present invention includes a workpiece 1, an annular electromagnetic heating device 2 and a workpiece thickness monitoring unit, and also includes a pressure unit, a temperature sensor 4 and a controller;

[0033] The workpiece 1 is formed by stacking several wafers and several welding pieces in an interlaced manner; the workpiece 1 is placed inside the annular electromagnetic heating device 2;

[0034] The pressure unit includes an air source 31 and a cylinder 33, and the air source 31 and the cylinder 33 are connected through an air supply pipeline, and an electromagnetic valve 32 is also arranged on the air supply pipeline, and the electromagnetic valve 32 is used to control the opening and closing of the air supply channel;

[0035] The upper and lower surfaces of the workpiece 1 are provided with a lining plate ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap