Positioning device and method based on plastic pipe cutting

A technology of positioning device and plastic pipe, applied in the field of plastic pipe processing, can solve the problems of inaccurate cutting, large error, easy shaking of the plastic pipe, etc., and achieve the effect of avoiding the knife and cutting quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

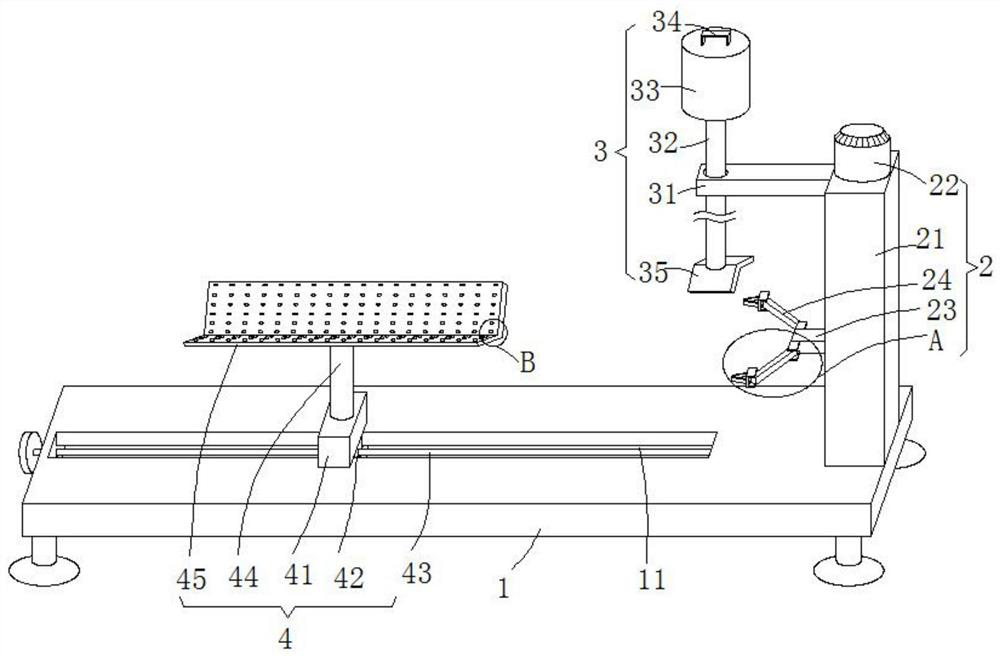

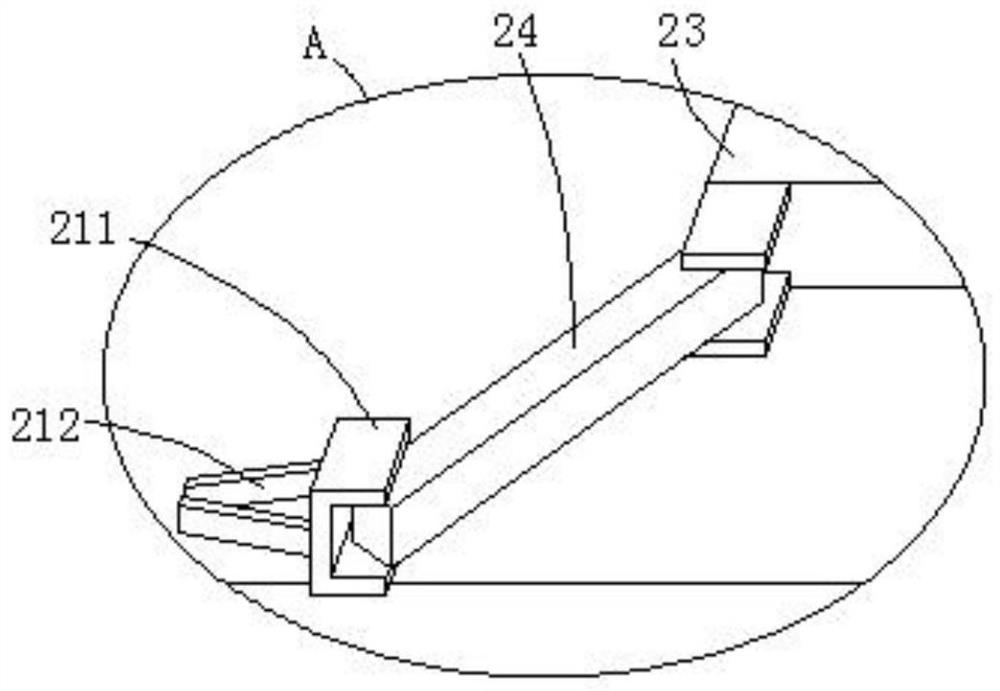

[0027] see Figure 1-4 , this embodiment provides a positioning device and a positioning method based on plastic pipe cutting, including a base 1 and a transmission mechanism 2, the upper end of the base 1 is provided with a support mechanism 4 that can move horizontally to adjust the support position, by moving horizontally along the upper end of the base 1 Adjust the position of the support mechanism 4, and then use the support mechanism 4 to support the plastic pipe to be cut. The transmission mechanism 2 is arranged on the upper right side of the base 1, and the left side of the transmission mechanism 2 is provided with a press for rolling and pressing the plastic pipe. Combining mechanism 3, using pressing mechanism 3 to press the upper end of the plastic pipe, can cooperate with supporting mechanism 4 to position and clamp the plastic pipe to be cut, and use transmission mechanism 2 to drive the plastic pipe to rotate between supporting mechanism 4 and pressing mechanism ...

Embodiment 2

[0036] see Figure 1-4 , made further improvement on the basis of embodiment 1:

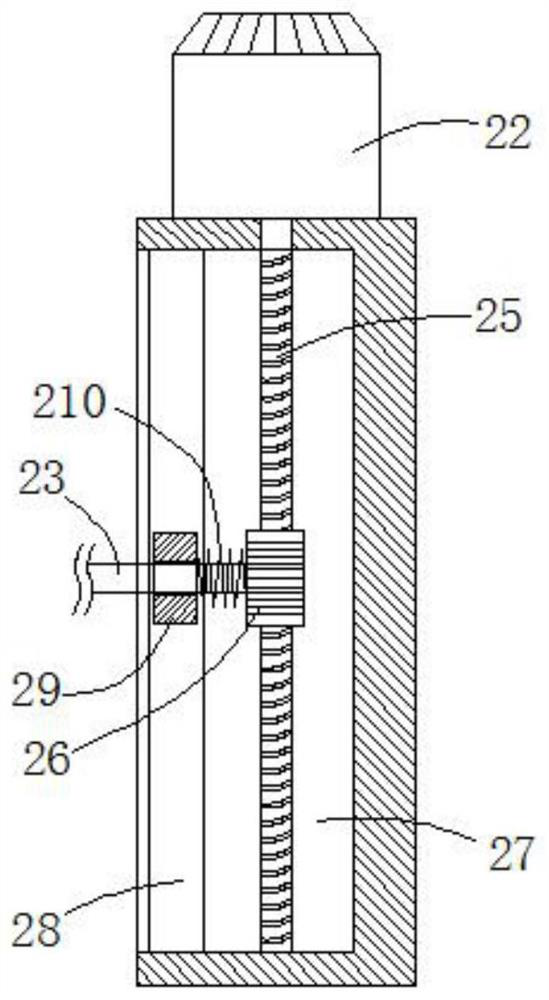

[0037] In order to solve the problem of how to ensure that the worm gear 25 and the worm screw 26 are meshed together in real time, the outer wall of the extension beam 23 is slidably adjusted with a spring 210 between the limit slider 29 and the worm screw 26, and the spring 210 is used to connect the limit slider 29 and the worm screw 26. 26 can be jacked up in real time, and the turbine 26 can be jacked up to the worm screw 25 side, so as to ensure that the turbine 25 and the worm screw 26 are meshed together in real time to realize the transmission of power.

[0038] In order to further solve the problem of how to avoid the plastic pipe placed on the V-shaped support block 45 from shaking during the cutting process, the top of the suspension rod 32 is fixedly provided with a counterweight column 33, and the inverted V-shaped pressing plate 35 is matched by the counterweight column 33. Heavy,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com