Ship paddle installation engineering vehicle

A technology for engineering vehicles and ships, which is applied to ships and other directions, can solve the problems of limited installation space, high center of gravity, small support points, etc., and achieve the effects of smooth leveling, high leveling, convenience and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

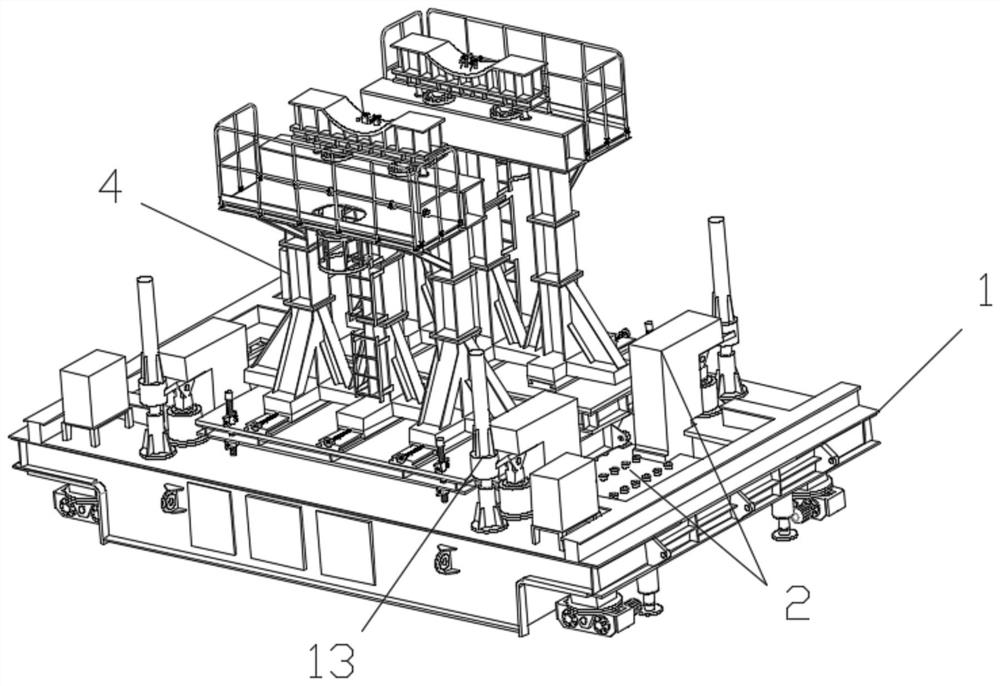

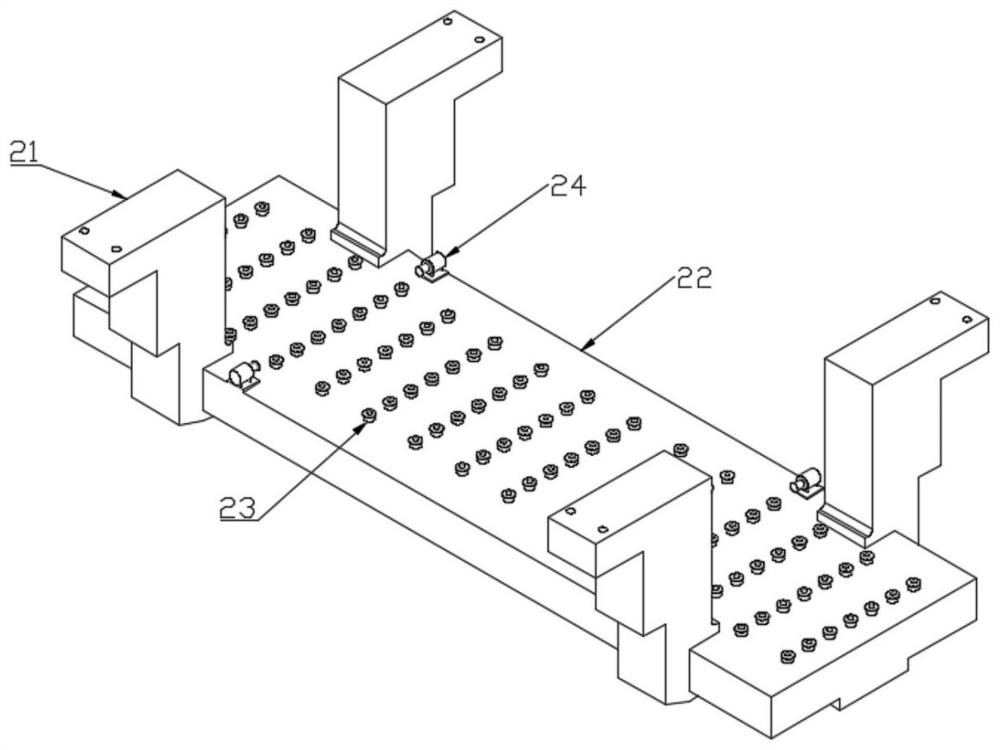

[0075] Such as Figure 1 to Figure 21 As shown, a ship propeller installation engineering vehicle of the present invention includes a mobile platform 1, and the middle part of the mobile platform 1 is provided with a horizontal lifting platform 2 through a lifting mechanism 13; the lifting platform 2 is provided with a paddle platform 4;

[0076] The four corners of the bottom of the mobile platform 1 are provided with traveling wheel mechanisms 11, and each traveling wheel mechanism 11 is also provided with a supporting mechanism 10; the traveling wheel mechanisms 11 are erected on the assembled track;

[0077] The side of the mobile platform 1 is provided with a mobile platform lifting lug 19; the bottom of the mobile platform 1 is fixed with a hydraulic pump station 17; the upper surface of the mobile platform 1 is also provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com