Water-based coating heat-sealing adhesive, coating process and application of water-based coating heat-sealing adhesive in medical dialyzing paper

A water-based coating and coating process technology, which is applied to devices, coatings, adhesives and other directions for coating liquid on the surface, which can solve the problems of easy generation of paper wool and paper scraps, large amount of glue, and large peel strength requirements. Achieve the effect of low volatile organic compound content, simple manufacturing process and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

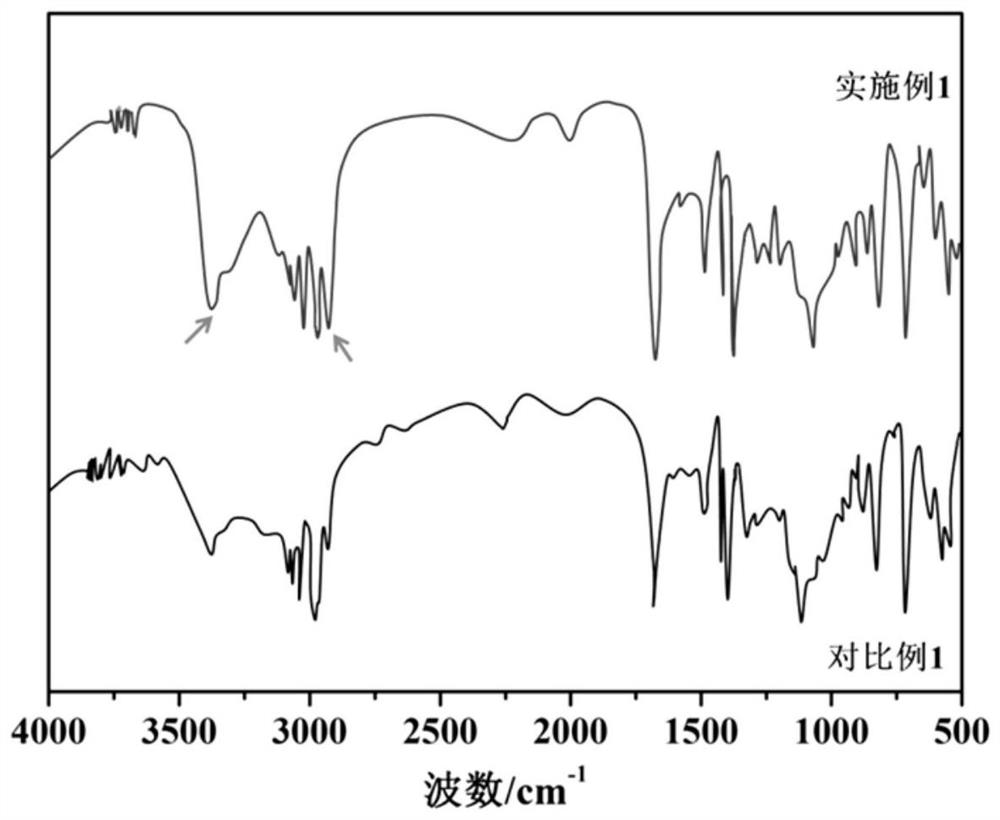

Image

Examples

Embodiment 1

[0026] The raw material components of a water-based coating heat-sealing adhesive include, in parts by weight, 50 parts of water, 22 parts of butyl acrylate, 20 parts of styrene, 1.5 parts of acrylic acid, 2.5 parts of (Z)-capsaicin, 2 parts of ten Sodium dialkyl sulfate, 1 part alkylphenol ethoxylate, 0.45 part ammonium persulfate.

[0027] A kind of preparation of water-based coating heat-sealing glue:

[0028] S1: Dissolve sodium lauryl sulfate and alkylphenol polyoxyethylene ether in tap water, stir and dissolve with a glass rod to obtain an emulsifier solution; dissolve ammonium persulfate in tap water to obtain an initiator solution;

[0029] S2: Mix all the reaction monomers (butyl acrylate, styrene, acrylic acid, (Z)-capsaicin) in parts by weight, add 1 / 2 emulsifier solution, and stir at high speed for 0.5h under the action of a mechanical stirrer to obtain the pre- Emulsion;

[0030] S3: Put the remaining 1 / 2 of the emulsifier solution into a four-necked bottle equi...

Embodiment 2

[0035] The raw material components of a water-based coating heat-sealing adhesive include, in parts by weight, 42 parts of water, 18 parts of butyl acrylate, 19 parts of styrene, 1 part of acrylic acid, 1.5 parts of (Z)-capsaicin, 1 part of ten Sodium dialkyl sulfate, 1 part alkylphenol ethoxylate, 0.25 part ammonium persulfate.

[0036] The preparation of a water-based coating heat-sealing adhesive is the same as that in Example 1.

[0037] The coating process of the above-mentioned water-based coating heat-sealing adhesive is the same as that in Example 1.

Embodiment 3

[0039] The raw material components of a water-based coating heat-sealing adhesive include, in parts by weight, 56 parts of water, 24 parts of butyl acrylate, 22 parts of styrene, 2.5 parts of acrylic acid, 3 parts of (Z)-capsaicin, 2.5 parts of ten Sodium Dialkyl Sulfate, 1.5 Parts Alkylphenol Ethoxylates, 0.5 Parts Ammonium Persulfate.

[0040] The preparation of a water-based coating heat-sealing adhesive is the same as that in Example 1.

[0041] The coating process of the above-mentioned water-based coating heat-sealing adhesive is the same as that in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap