Compressed cloth with elastic effect and production method thereof

A cloth and elastic technology, which is applied in the fields of application, clothing, textiles and papermaking, etc., can solve the problem of high manufacturing cost of clothing, and achieve the effect of lightness, air permeability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 A kind of compressed cloth with elastic effect

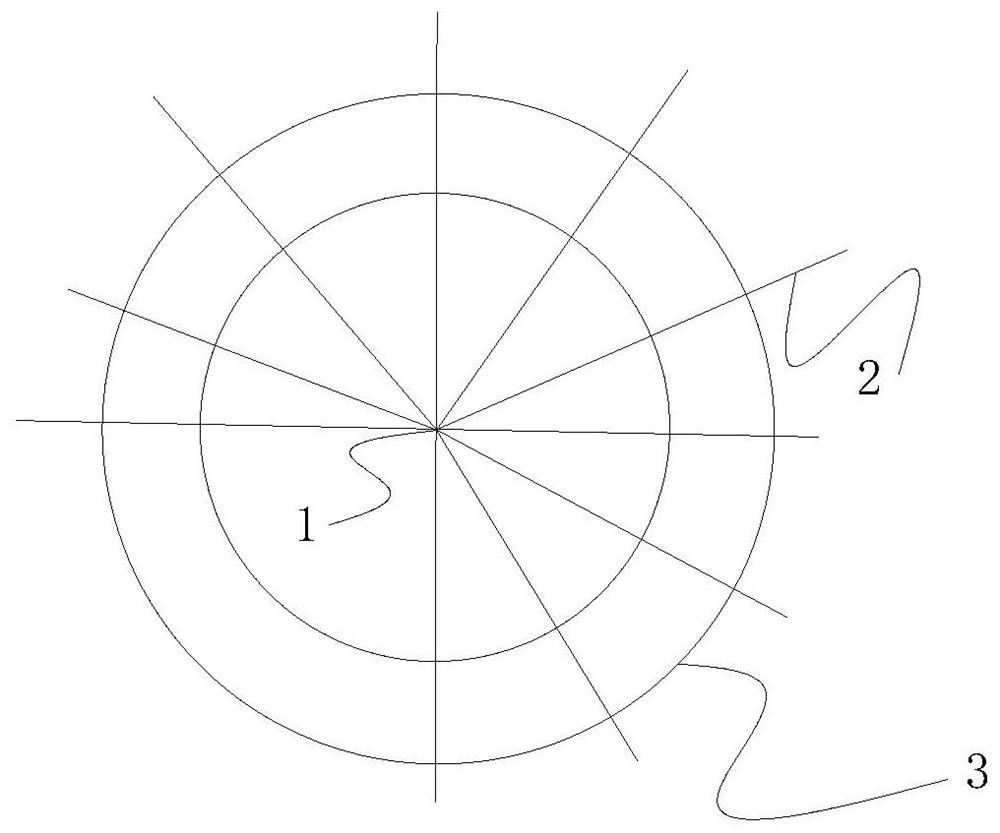

[0025] The compressed fabric is a single-sided fabric with stretching elasticity; as figure 1 As shown, the upper surface of the compressed fabric presents a concave-convex structure, and the concave part is a stretchable structure; the convex part is centered on the pressure point 1 set before weaving, and the closer to the pressure area, the weaving of the convex part The greater the density. The raised portion has a structure of divergent lines 2 extending outwards at the set pressure point 1 . The protruding part also includes a connecting wire 3 structure connecting the diverging wire structure 2 . The elastic force of the convex part is smaller than that of the concave part.

[0026] In Example 1, the compressed cloth with elastic effect is obtained, which is light and thin and has strong air permeability, and can well achieve the effect of moisture absorption and perspiration, and is suitable as a s...

Embodiment 2

[0027] Embodiment 2 A kind of compressed cloth with elastic effect

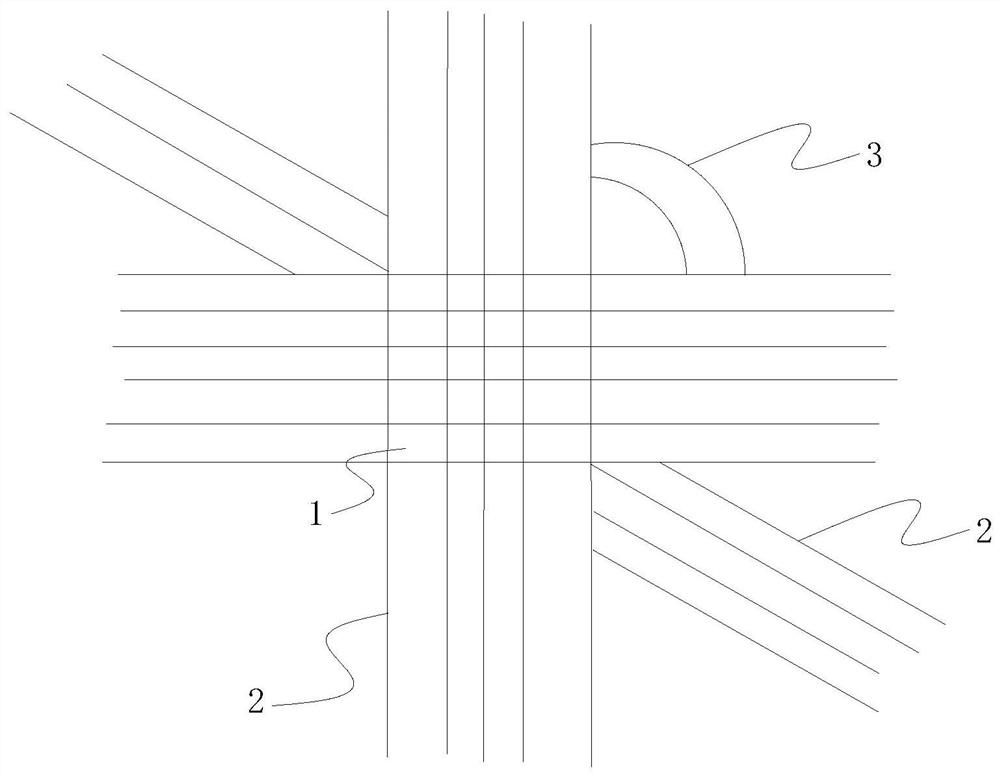

[0028] The compressed fabric is a single-sided fabric with stretching elasticity; as figure 2 As shown: the upper surface of the compressed fabric presents a concave-convex structure, and the concave part is a stretchable structure; the convex part is centered on the pressure zone 1 set before weaving, and the closer to the pressure zone 1, the The greater the weaving density. The convex part has a structure of divergent lines 2 extending outwards centered on the set pressure area 1 . The protruding part also includes a connecting wire 3 structure connecting the diverging wire structure 2 . The elastic force of the convex part is smaller than that of the concave part.

[0029] In Example 2, the compressed cloth with elastic effect was obtained. The core pressure area is rectangular, the pressure in this area is strong, and the surrounding pressure gradually decreases outward. The cloth is light and thin a...

Embodiment 3

[0030] Embodiment 3 Weaving of compressed cloth

[0031] The compressed fabric is a single jacquard fabric, which is obtained by weaving a single jacquard machine.

[0032] The specific steps are: input the preset knitting process in the computer software, wherein when the raised part is weaving, the flat needle does not go out of the needle cylinder, so that the yarn is stacked at the needle exit position, and a stretchable coil structure is formed on the lower surface ; The number of intervals between adjacent tucks is 1. The concave raised part of the compressed cloth is woven by looping.

[0033] Correspondingly connect the yarn into the number of yarn feeders according to the computer version of the graphics;

[0034] Among them, the raised part is woven with 75D / 36F polyester and 40D spandex yarn, while the concave part is woven with 150D / 144F polyester and 40D spandex yarn. In this way, the elastic force of the convex portion is smaller than that of the concave porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com