A waterproof lightweight pressure relief wall

A pressure relief, lightweight technology, applied in the direction of walls, buildings, building components, etc., can solve problems such as water leakage, and achieve the effect of preventing water accumulation, preventing water leakage, and being conducive to grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

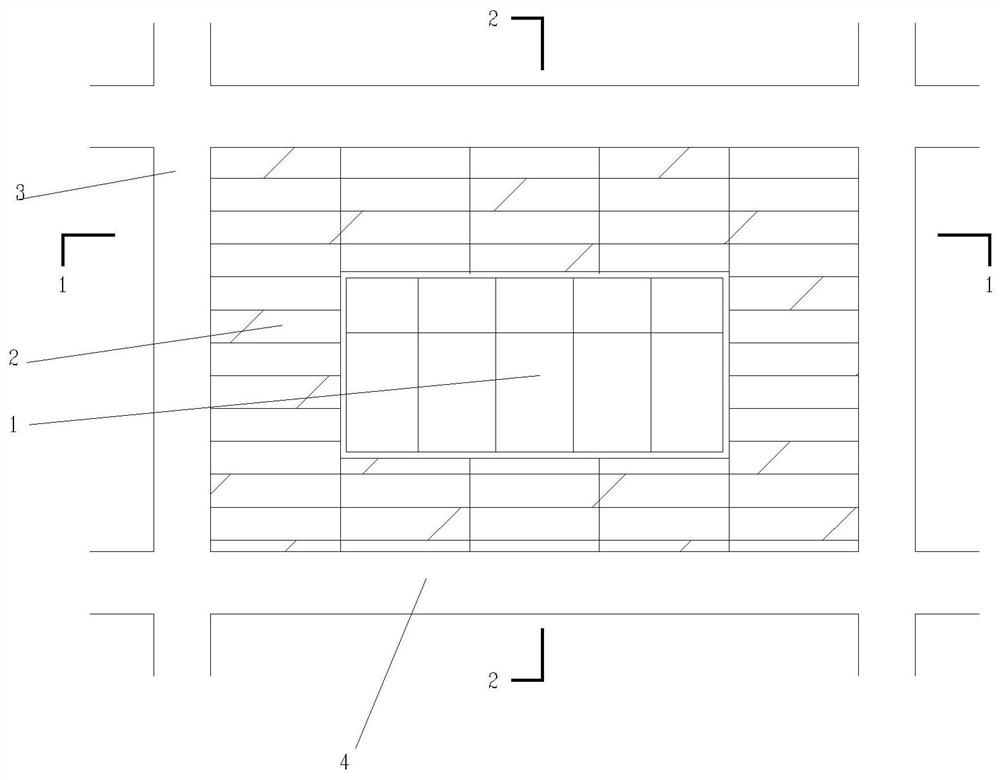

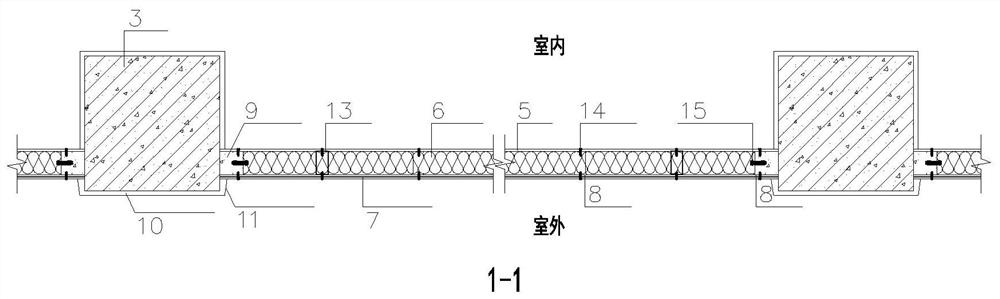

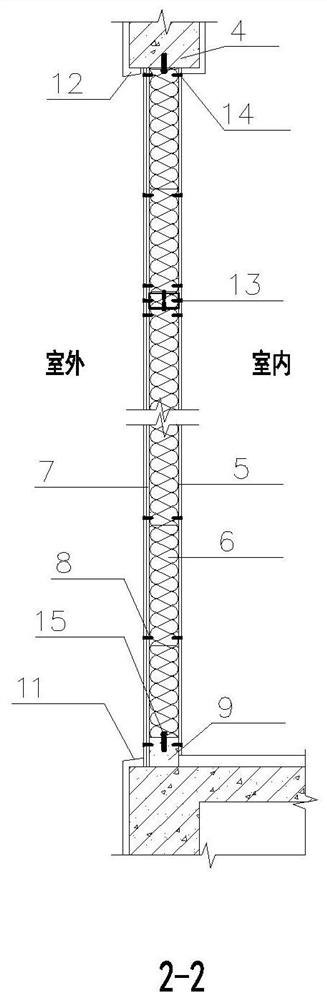

[0029] A waterproof, lightweight pressure relief wall constructed as figure 1 As shown, a pressure relief wall 2 is arranged around the window 1, and two vertical structural columns 3 on the left and right and two horizontal structural beams 4 on the upper and lower sides form a square for fixing the pressure relief wall 2. like figure 2As shown, the pressure relief wall 2 is provided with a pressure relief plate. The pressure relief plate is divided into an inner pressure relief plate 5 and an outer pressure relief plate 7 according to the location. The inner pressure relief plate 5 is close to the indoor side, the outer pressure relief plate 7 is close to the outdoor side, and the outer pressure relief plate 7 is a double-layer staggered pressure relief plate, which can effectively prevent water leakage at the joints. Filled rock wool 6 is filled between the inner pressure relief plate 5 and the outer pressure relief plate 7 . The two pressure relief plates are connected ...

Embodiment 2

[0037] The difference with embodiment 1 is to fill the parameters of the preparation method of rock wool 6, and the concrete steps are as follows,

[0038] (1) Raw material preparation: After calcining the coarse basalt at 700°C, add glycerol for 0.5h ball milling to obtain basalt particles; in parts by mass, mix 30 parts of α-methacrylic acid and 70 parts of water to obtain a waterproof coating The dispersion liquid of the layer; take 0.1 part of 70%wt hydrogen peroxide as the initiator; the total usage amount of the dispersion liquid of the waterproof coating and the initiator is 5% of the mass of rock wool;

[0039] (2) Preparation of waterproof rock wool yarn: Mix 33 parts of basalt particles and 8 parts of palygorskite evenly, put it into a heating furnace and melt it into magma, rotate and blow it into rock wool yarn, and disperse the waterproof coating during the blowing process. The liquid and the initiator are mixed and evenly sprayed on the rock wool yarn to obtain w...

Embodiment 3

[0043] The difference with embodiment 1 is to fill the parameters of the preparation method of rock wool 6, and the concrete steps are as follows,

[0044] (1) Preparation of raw materials: After calcining the crude basalt at 800°C, add glycerol for ball milling for 2 hours to obtain basalt particles; in parts by mass, 50 parts of α-methacrylic acid, 2 parts of defoamer, 2 parts of anti-foaming agent The precipitation agent, 50 parts of filler and 100 parts of water are mixed evenly to obtain the dispersion of the waterproof coating; 4 parts of 70% wt hydrogen peroxide are taken as the initiator; the total usage of the dispersion of the waterproof coating and the initiator is the mass of rock wool 10% of;

[0045] (2) Preparation of waterproof rock wool yarn: Mix 35 parts of basalt particles and 12 parts of palygorskite evenly, put it into a heating furnace and melt it into magma, rotate and blow it into rock wool yarn, and disperse the waterproof coating during the blowing pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com