Equipment and method for repairing cracks in wallboards with magnetic mortar

A magnetic and mortar technology, applied in the direction of building maintenance, construction, building construction, etc., to achieve the effect of improving the scope of application, increasing the degree of accuracy, and improving the degree of filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

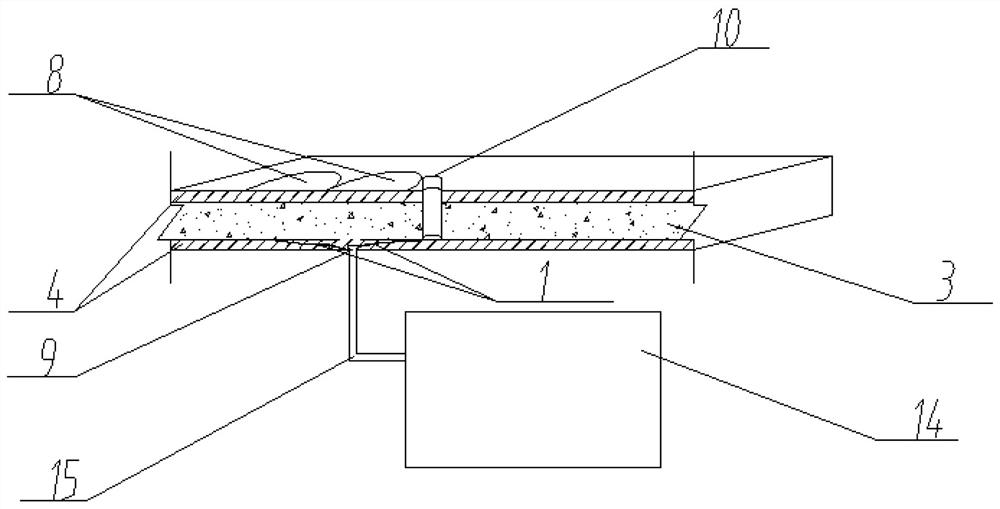

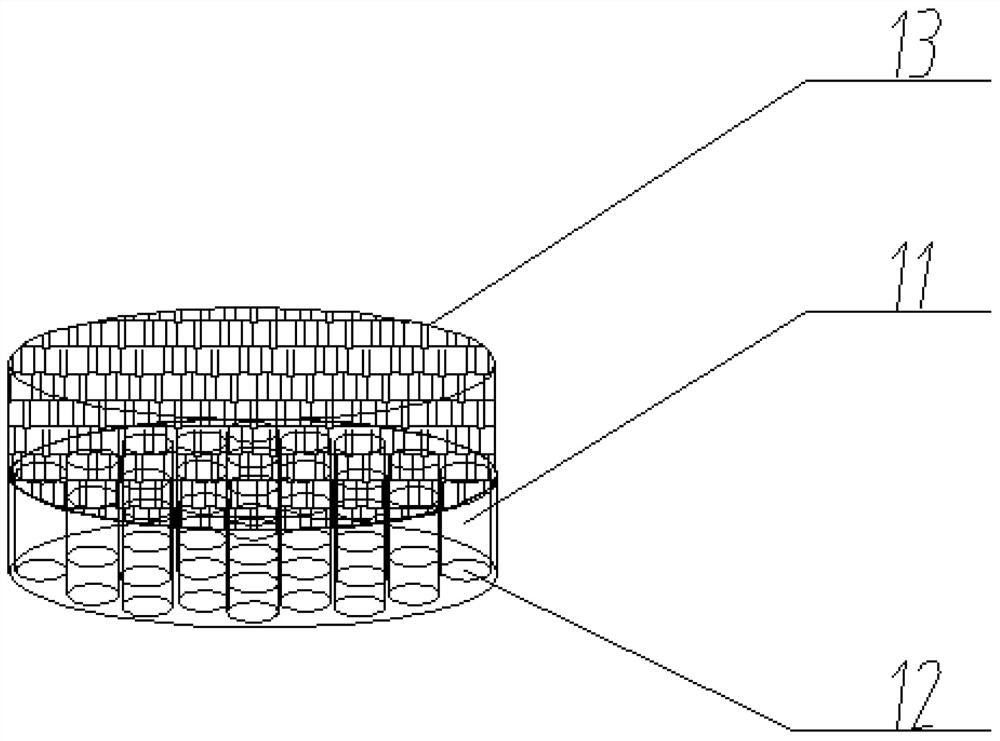

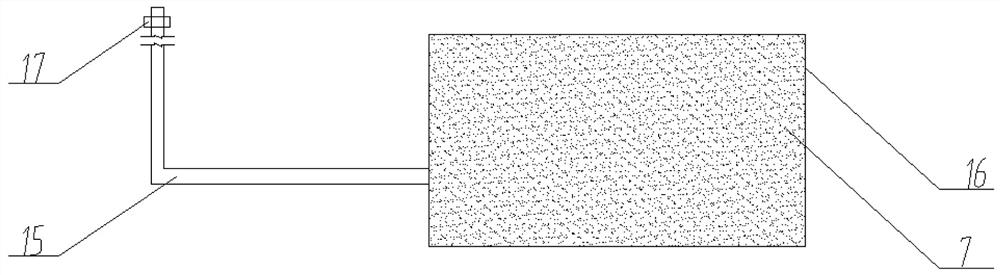

[0051] see Figure 1-4 A device for repairing cracks in wallboards with magnetic mortar, which includes an ultrasonic detector for detecting the specific position, direction and length and width data of a crack 1 inside a floor slab; includes a grouting device 14 for grouting the inside of the crack 1 , the grouting device 14 communicates with the grouting hole 9 processed at the position of the crack 1 through the grouting pipe 15; it includes an attractor 8 for guiding the magnetic mortar 7 injected into the crack 1, and the attractor The magnets 8 are arranged in the crack extension direction according to the direction of the crack 1, and are located on one or both sides of the repair structure, and can be comprehensively arranged using a plurality of attractors 8 with different areas, shapes or magnetic sizes according to the actual situation. The present invention uses magnetic mortar to fill the cracks in the floor and wall structures, uses attractors to guide the flow o...

Embodiment 2

[0070] The method for repairing cracks by using the equipment for repairing cracks in wallboards with magnetic mortar comprises the following steps:

[0071] Step1.1: Material preparation: Prepare materials and equipment required for filling cracks, including ultrasonic detectors, raw materials for magnetic mortar, drilling equipment, attractors, grout storage, grouting devices, rubber gaskets and grouting conduits;

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com