Integrated electrical and mechanical pump starting device

A pump device and machinery technology, which is applied to liquid variable capacity machinery, components of a pumping device for elastic fluid, mechanical equipment, etc., can solve problems such as the failure of the pump to start normally, the insufficient capacity of the transformer and the backup generator, etc. To ensure the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

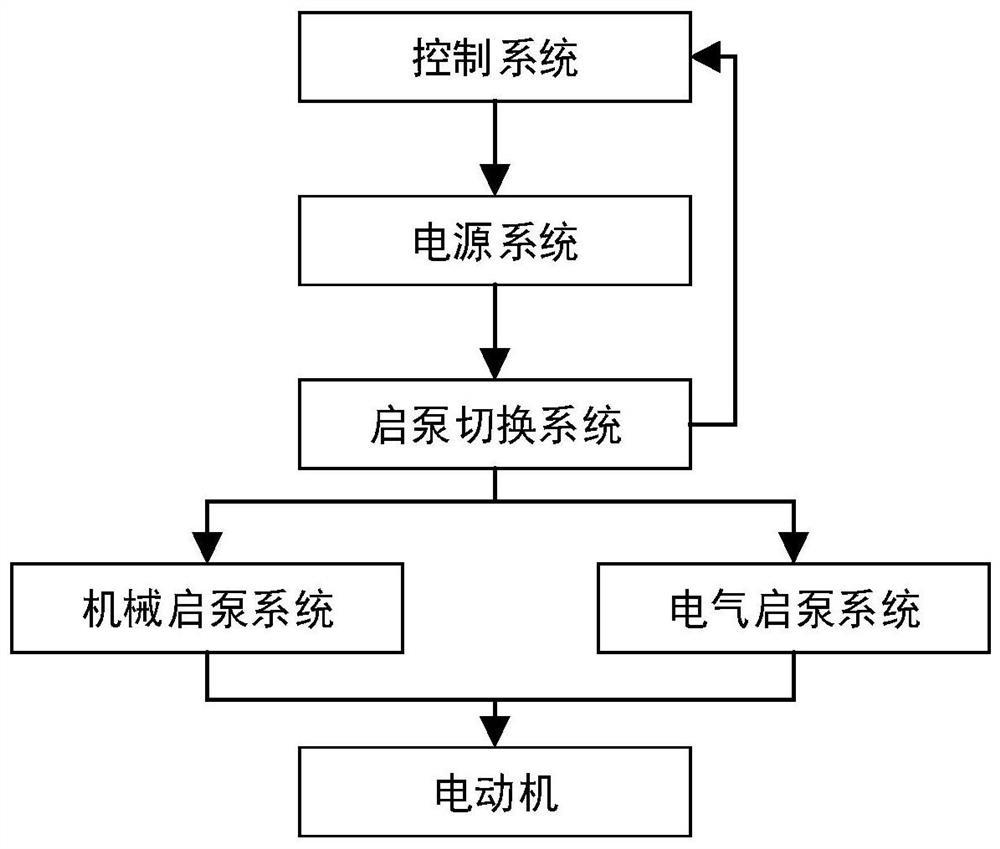

[0034] Integrated electrical and mechanical start pump device, if included figure 1 As shown, including the power supply system, a pump switching system, a mechanical start-pump system, an electrical setup system, a motor and control system, a power supply system and a pump switching system, and the pump switching system is separately connected to the mechanical starting pump system, electrical lane System connection, mechanical start pump system, electrical start pump system is connected to the motor. The pump switching system is used to switch the mechanical start pump system and the electrical start system, and the power system is used to power the motor to the motor by the electrical setup pump system or mechanical start pump system after the pump system, that is, when the pump switching system is switched. When the system is bucking, the motor is booted by the power supply system, and the anti-pressing start is started; when the pump switching system switches the mechanical s...

Embodiment 2

[0038] The present embodiment is different from the first example:

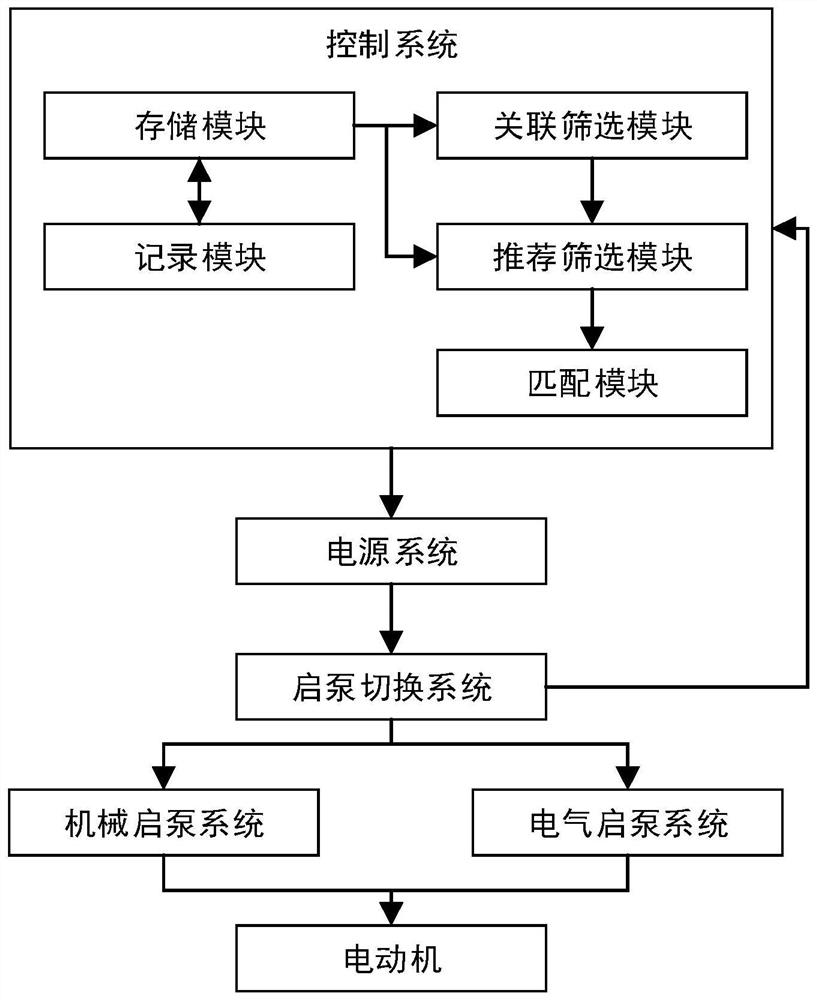

[0039] Control systems include storage modules, associated filter modules, recording modules, and recommended filter modules, such as attached figure 2 Indicated.

[0040] The storage module pre-stored area water pump information and maintenance record table, the area pump information includes the pipe network information of each water pump and the water pump coordinates of each water pump, the maintenance record table records the planned maintenance date, maintenance date and overhaul, maintenance record table The pump is marked as an index to store.

[0041]The control system is also used to obtain fireplaces, and screen the associated water pump according to the fireplaces and regional water pump information. The fire site is uploaded by the fire management department through the main control terminals used, such as a computer. Specifically: the associated screening module presets the number of overhaul quanti...

Embodiment 3

[0051] The difference between this embodiment and the second embodiment is:

[0052] The control system also includes a power storage filter module, a power storage module is used to extract the next maintenance date in the overhaul record table, and the next inspection date is a plan for maintenance record table. The power storage module is also used to calculate the time difference value of the next time the date and the current date. When the time difference is less than the preset time threshold, the corresponding associated water pump corresponding to the power supply water pump. In this embodiment, the time threshold is 15 days. The control system is also used to control the power supply module corresponding to the electric water pump to supply power to the electric storage module.

[0053] In other embodiments, the power storage module is also used to match the water pump to be powered and recommended, and update the water pump to be powered according to the matching item. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com