Hydraulic filling valve assembly and hydraulic assembly having filling valve assembly

A technology for filling valves and components, applied in servo motor components, presses, manufacturing tools, etc., can solve problems such as consumption and high consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

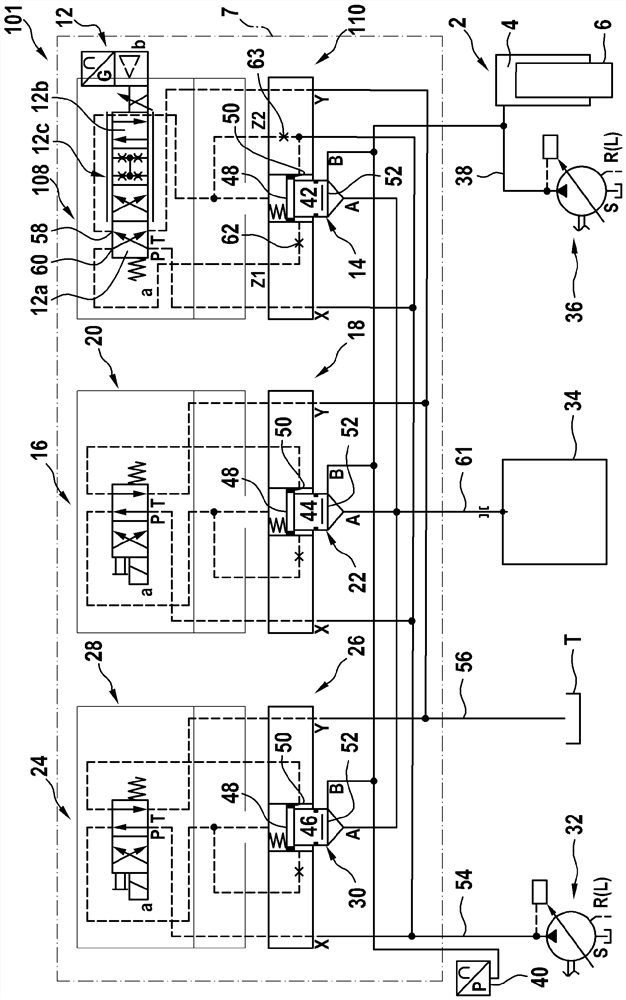

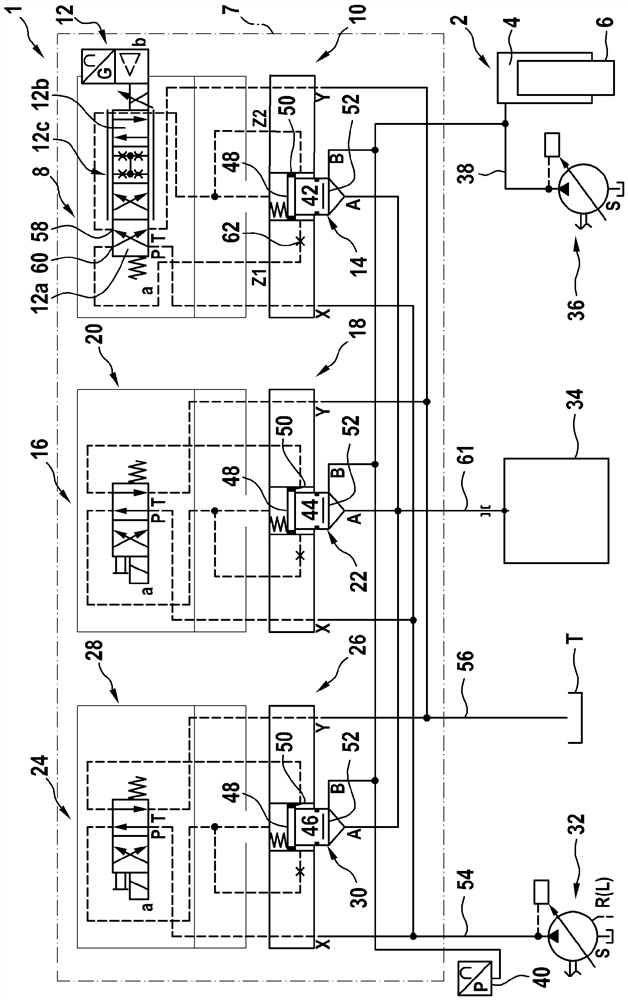

[0058] figure 1 A hydraulic line diagram of a large pressure machine of the first embodiment is shown. The large press has one or at least one hydraulic cylinder 2 having a pressure chamber 4, the pressure chamber being locally limited by the piston 6. In the illustrated embodiment, the gravity acceleration G acts on the piston 6, so that the gravity acceleration allows the piston to accelerate the direction of ziehkissen (not shown) to form a fast stroke, wherein the pressure chamber 4 is increased. .

[0059] In order to control the pressure chamber 4 and release the pressure medium from the pressure chamber 4, the pressure chamber can be fluidly coupled through the valve 8, 16, 24 and the Treated pressure medium container or pressure medium memory 34.

[0060] In order to apply the pressure of the hydraulic cylinder 2, the large pressure machine has a high-pressure medium source 36 in an open hydraulic circuit, which is fluidly coupled to the pressure chamber 4 through the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com