SF6 waste gas continuous recovery method and recovery device

A technology of exhaust gas recovery and recovery method, which is applied in the direction of measuring device, volume measuring instrument/method, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

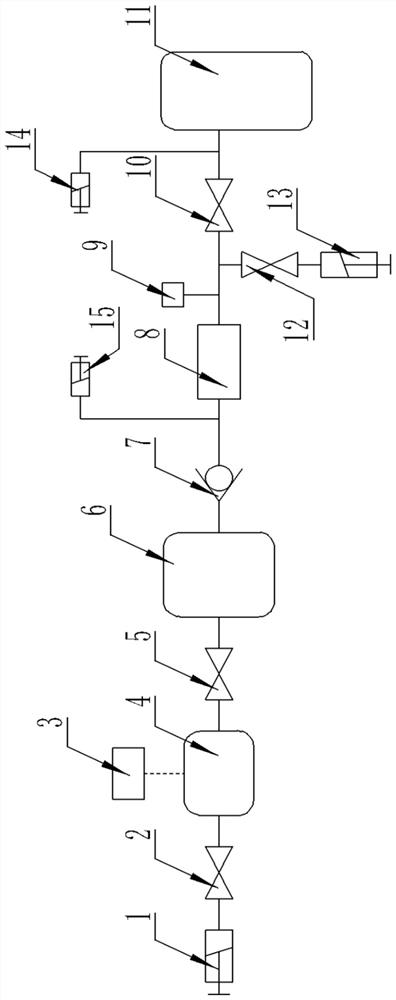

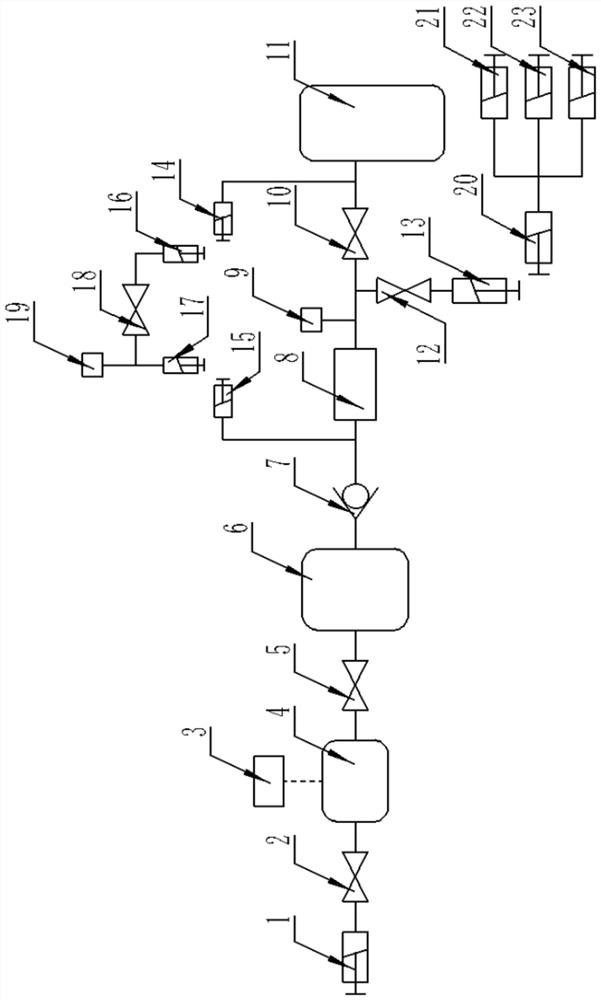

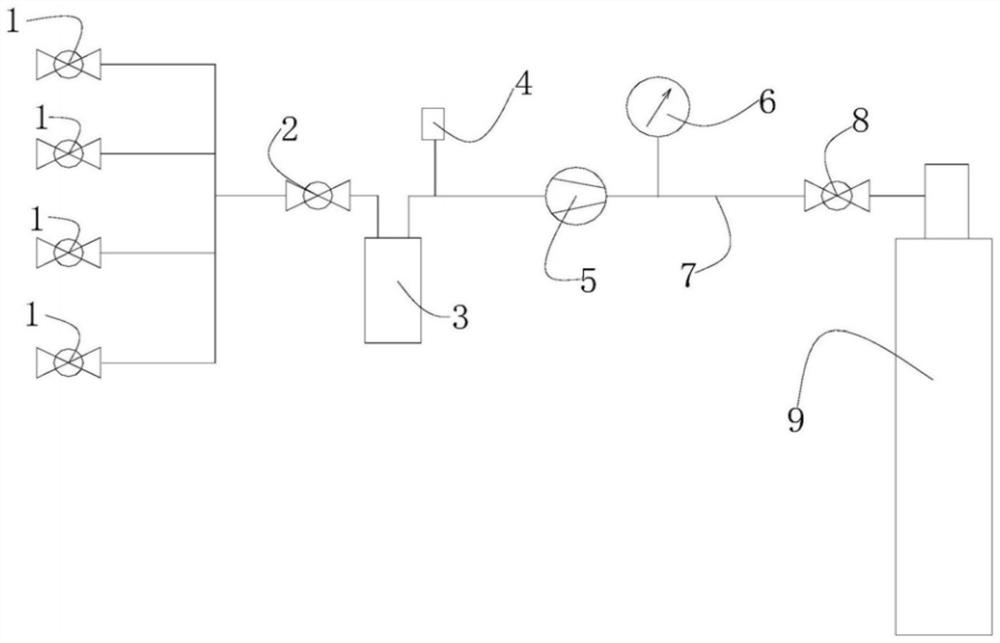

[0029] Such as figure 1 and figure 2 As shown, the recovery device includes: a recovery interface 1, a first valve 2, an ultrasonic distance measuring sensor 3, a buffer bag 4, a second valve 5, a purification unit 6, a one-way valve 7, a compressor 8, and a first pressure detection unit 9 , the third valve 10, the built-in recovery bottle 11, the fourth valve 12, the air outlet port 13, the first quick plug male head 14, the second quick plug male head 15, the first quick plug female head 16, the second quick plug female head 17. The fifth valve 18, the second pressure detection unit 19, the adapter 20, the first expansion interface 21, the second expansion interface 22, and the third expansion interface 23.

[0030] The recovery interface 1, the first valve 2, the buffer bag 4, the second valve 5, the purification unit 6, the one-way valve 7, the compressor 8, the third valve 10, and the built-in recovery bottle 11 are sealed and connected head to tail in series by pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com