Strain benchmarking method of hub bearing dynamic test beds

A wheel bearing and dynamic test technology, which is applied in the field of wheel bearings, can solve the problems of varying test life results, affecting force effects, and inability to determine factors affecting life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: As shown in the accompanying drawings, the strain benchmarking method of the wheel hub bearing dynamic test bench mainly includes the following steps:

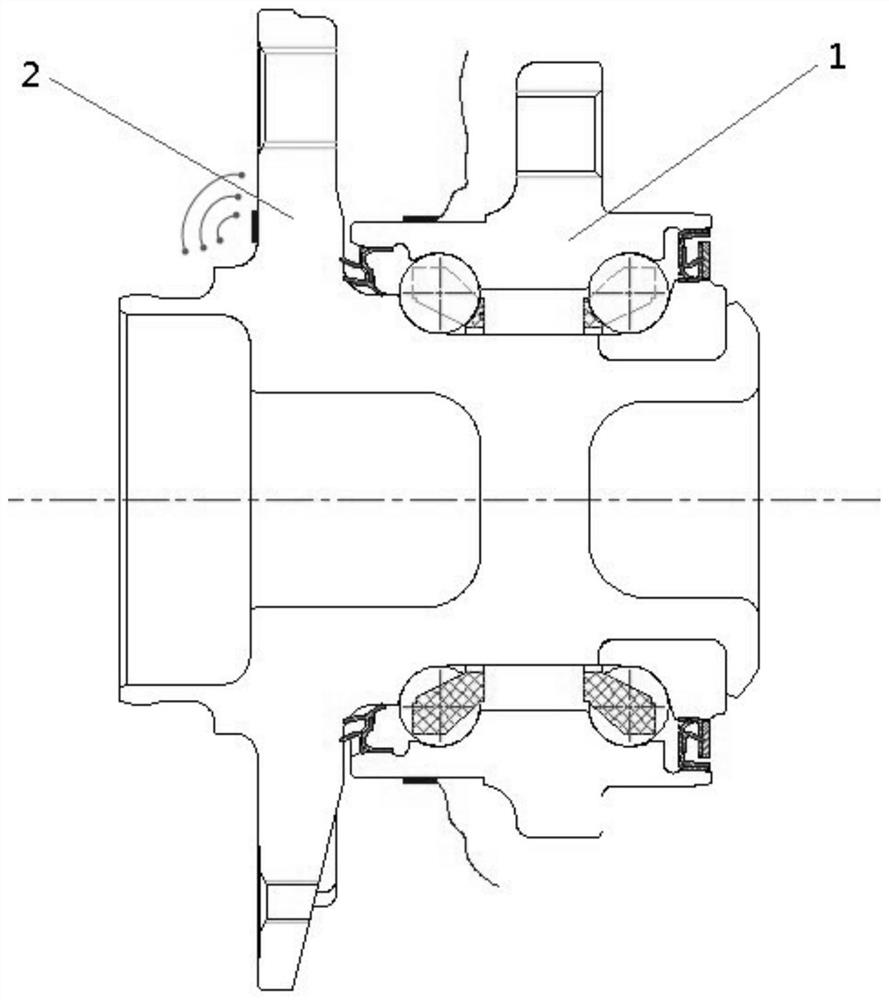

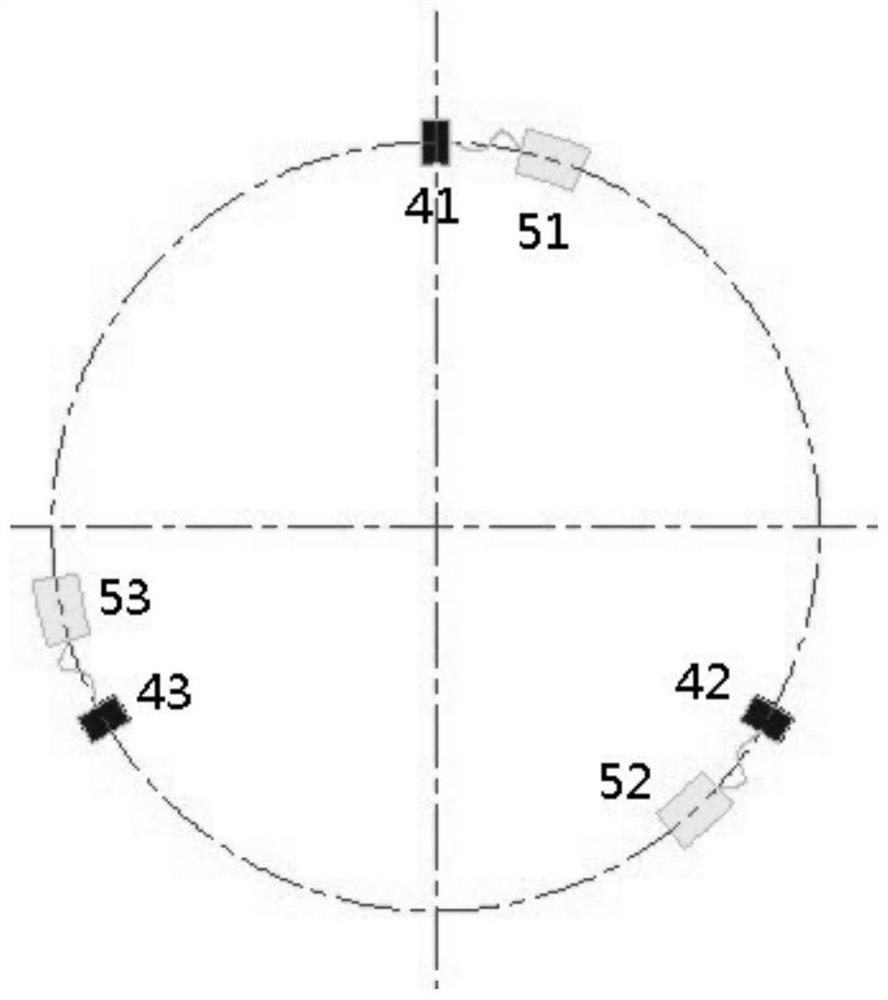

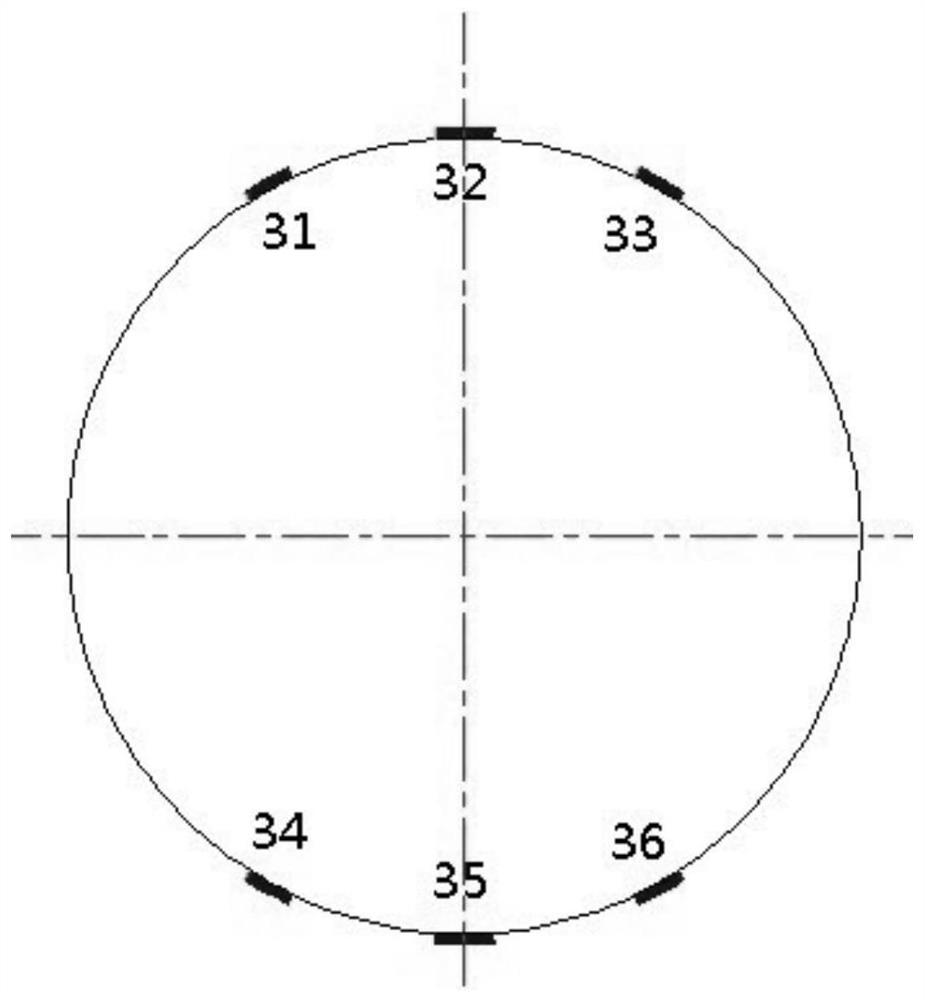

[0029] 1) Production of strain-type standard sample 5: as attached figure 1 As shown, select a hub bearing unit composed of outer ring 1 and flange 2, and perform grinding treatment on six areas of the outer surface of outer ring 1, so that the surface roughness is controlled within Ra0.8, and then use air-curing glue ( Such as 502 glue) respectively paste the strain gauge A31, strain gauge B32, strain gauge C33, strain gauge D34, strain gauge E35, and strain gauge F36 on the surface of the outer ring 1. The outer ring 1 is a non-rotating part in the work of the hub bearing. The orientation is kept in the vertical direction, and strain gauge B32 and strain gauge E35 are respectively arranged in the direction of the vertical line of the wheel, and strain gauge A31, strain gauge C33, strain gauge D34, strain...

Embodiment 2

[0045] Embodiment 2: adopt the inventive method, carry out the test of 1 standard test rig and 1 non-standard test rig respectively, choose the 6th step in 8 loading steps to carry out the analysis and evaluation of test collection data, in the 6th step condition Down:

[0046] The outer ring 1 is a non-rotating part, and the output results of the 6 strain gauges on it are shown in Table 2:

[0047] Table 2 Outer ring 1 strain output result table

[0048] Strain gauge number Standard test bench strain (μeps) Non-standard test bench strain (μeps) Relative error(%) evaluate 31 193 202 4.3 OK 32 265 269 1.5 OK 33 186 194 4.4 OK 34 -123 -120 -3.2 OK 35 -242 -239 -1.2 OK 36 -133 -129 -3.0 OK

[0049] Flange 2 is a rotating part, and the output results of the three strain gauges on it are all sinusoidal, as shown in the attached Figure 5 The signal output result graph of the strain gauge G41 is shown.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com