Method for quickly positioning and measuring dead load condition of in-service bridge structure

A bridge structure, positioning measurement technology, applied in the field of bridge structure, can solve problems such as time-consuming, dependence on professional quality and subjective judgment, lack of quantitative scientific basis, etc., to improve the efficiency of measurement and control, and quickly calculate the structure size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

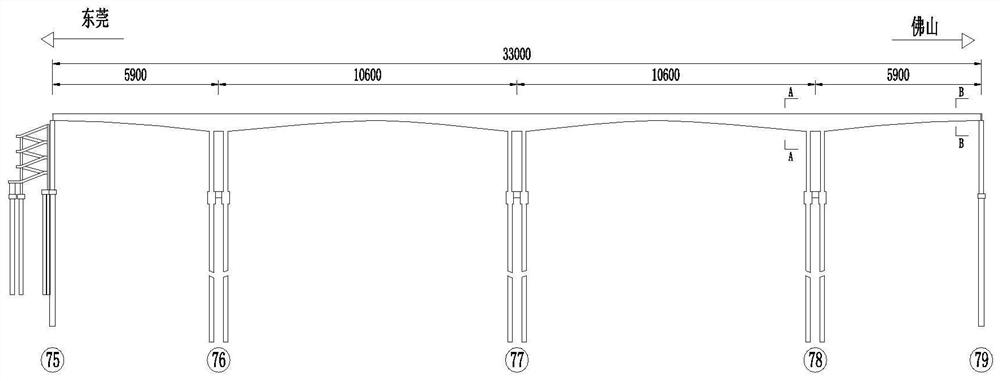

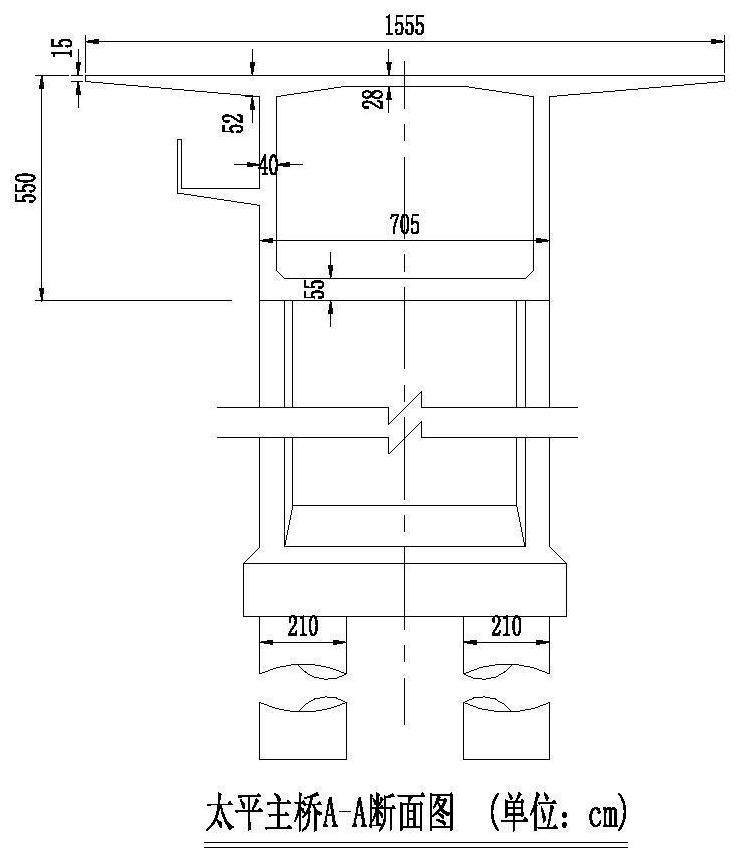

[0028] The following is attached Figure 1-9 The present invention is described in further detail.

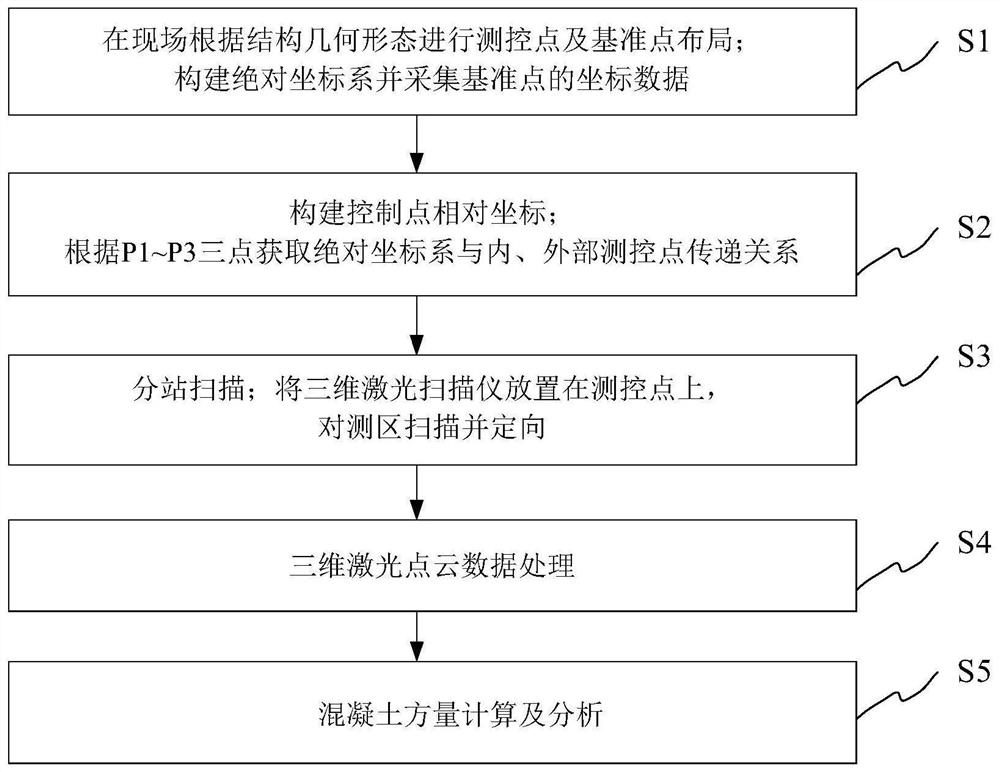

[0029] refer to figure 1 As shown, the embodiment of the present invention provides a method for quickly locating and measuring the dead load condition of an in-service bridge structure using three-dimensional laser scanning technology combined with local scale measurement, including the following steps;

[0030] S1. On-site layout of measurement and control points and reference points according to the structural geometry; the measurement and control points include: external measurement and control points of the structure and internal measurement and control points of the structure; the reference points are three absolute references arranged at preset distances around the adjacent structure Points P1~P3, based on the total station to construct an absolute coordinate system (OXYZ) for the three absolute reference points P1~P3 A , and collect the coordinate data of three absolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com