Laying device and method for high-voltage cable with special-shaped lumen

A technology of high-voltage cables and special-shaped tubes, which is applied in the field of high-voltage cable laying devices with special-shaped lumens, and can solve problems such as reducing laying time and cost, and inconvenient bending of power cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

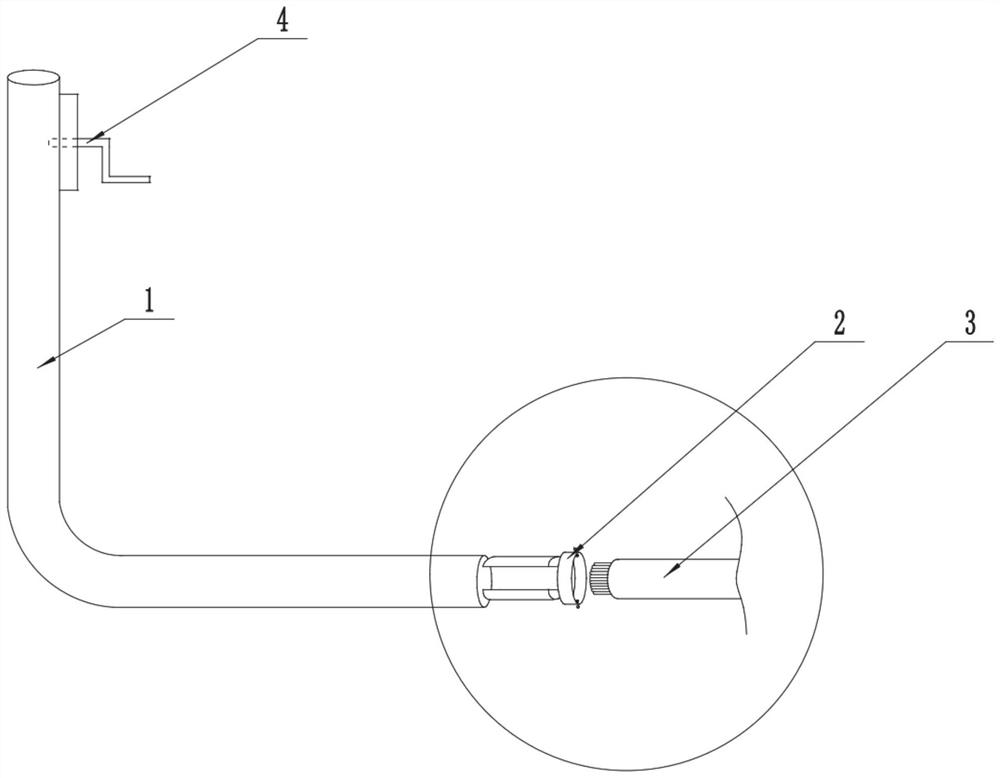

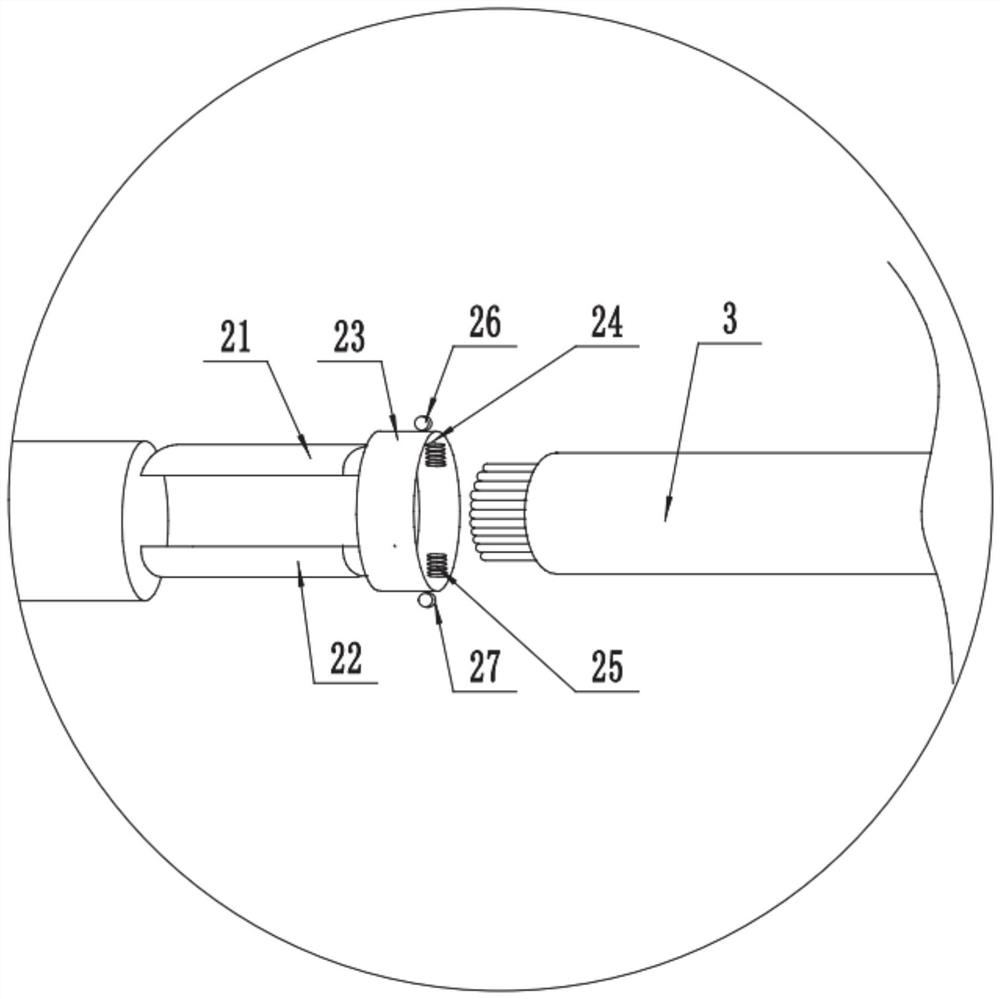

[0028] In a typical implementation of the present invention, this embodiment discloses a special-shaped lumen high-voltage cable laying device, including a pipe 1 and a clamping mechanism 2, the clamping mechanism 2 is arranged inside the pipe 1, and the clamping mechanism 2 can The inner wall of the pipe 1 is in contact; the end of the pipe 1 is provided with a handle, and the handle is connected to the clamping mechanism 2 through a traction cable (not shown in the figure), and the pipe 1 can be bent. For the inner bending section 12 and the outer bending section 12, the clamping mechanism 2 is provided with at least two arc-shaped pieces that are in contact with the inside of the pipe 1, and one of the arc-shaped pieces is located on one side of the inner bending section 12 of the pipe 1, wherein The other arc-shaped part is located on the side of the outer bending section 12 of the pipe 1 .

[0029] More specifically, in this embodiment, the pipe 1 is made of PPR material,...

Embodiment 2

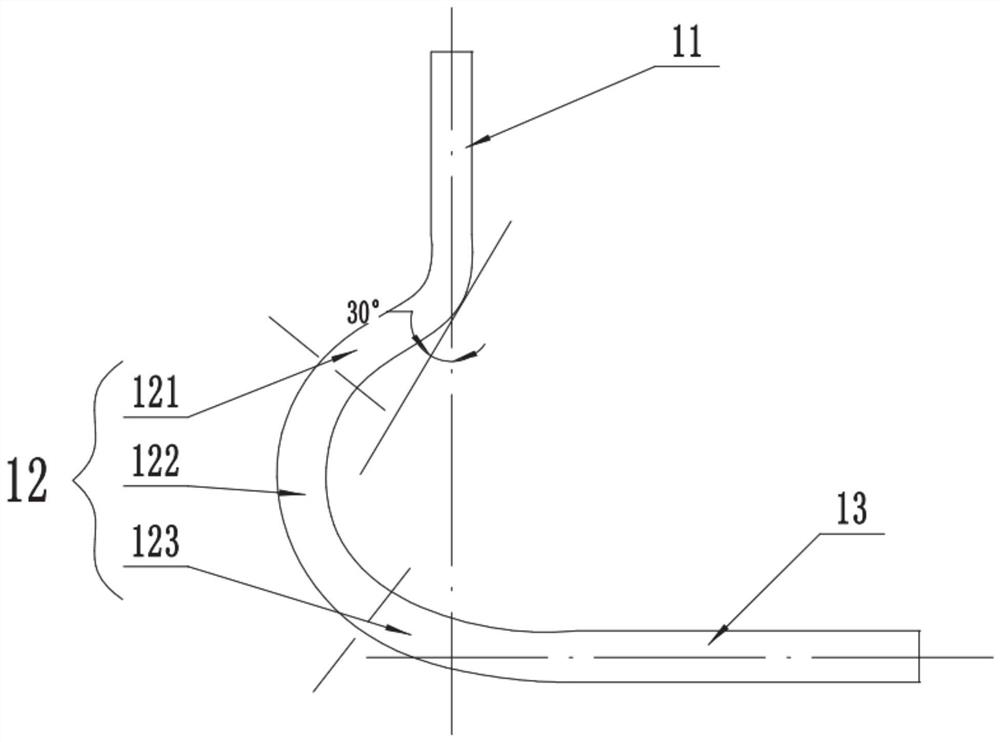

[0055] In an exemplary embodiment of the present invention, as image 3 As shown, this embodiment discloses a special-shaped lumen high-voltage cable laying device. The difference from Embodiment 1 is that in this embodiment, the shape of the bending section 12 of the pipe 1 is different from that in Embodiment 1.

[0056] It should be noted that, in this embodiment, the plane passing through the central axis of the vertical section 11 and perpendicular to the horizontal section 13 is defined as the reference plane, the side of the reference plane away from the horizontal section 13 is the outside, and the side close to the horizontal section 13 is inside.

[0057] like image 3 As shown, in this embodiment, the bending section 12 is divided into a first bending part 121 , a first bending part 122 and a third bending part 123 which are connected to each other, wherein one end of the first bending part 121 is connected to The vertical section 11, the other end is connected to...

Embodiment 3

[0062] In a typical implementation of the present invention, this embodiment discloses a special-shaped lumen high-voltage cable laying device. The difference from Embodiment 1 is that the roller is replaced with a protrusion provided on the annular member 23 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com