Bilaterally-driven battery charging relay safety control system and method

A battery charging and bilateral drive technology, applied in battery overcharge protection, battery circuit devices, electric vehicle charging technology, etc. Risk of overcharge and explosion, low cost of modification, and effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

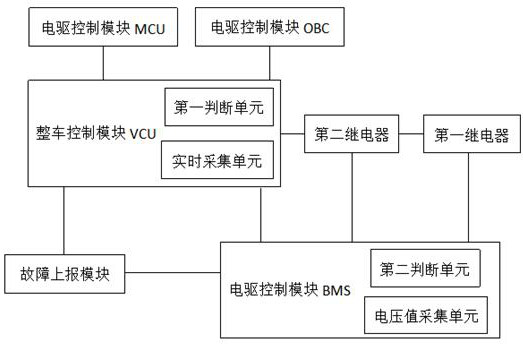

[0048] refer to figure 1 , the present embodiment provides a bilaterally driven battery charging relay safety control system,

[0049] Including electric drive control module BMS, vehicle control module VCU, first relay 1, second relay 2, battery pack, charging pile;

[0050] The charging pile provides power for charging the battery pack;

[0051] The first relay 1 and the second relay 2 realize the on-off of the charging circuit;

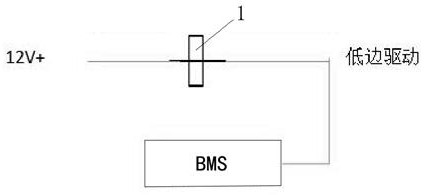

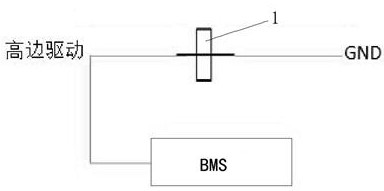

[0052] The electric drive control module BMS and the vehicle control module VCU are respectively connected to both ends of the first relay 1, and a second relay 2 is arranged between the vehicle control module VCU and the first relay 1;

[0053] When an overcharging fault occurs in the battery pack, if the first relay 1 is in a normal state, the first relay 1 is cut off by the electric drive control module BMS or the vehicle control module VCU to stop charging; if the first relay 1 is in a fault state, Then, the second relay 2 is cut off by the ...

Embodiment 2

[0068] refer to Figure 7 , the present embodiment provides a bilaterally driven battery charging relay safety control method, based on the bilaterally driven battery charging relay safety control system described in Embodiment 1, comprising steps:

[0069] S1. Determine whether the first relay 1 is in a normal state, if so, proceed to step S2, otherwise proceed to step S6;

[0070] S2. Determine whether the electric drive control module BMS is faulty, if there is a fault, execute step S3, if there is no fault, execute step S4;

[0071] S3. The fault reporting module transmits the fault information to the vehicle control module VCU, and executes step S5;

[0072] S4. The first judging unit judges whether the battery pack has an overcharge failure. If so, the electric drive control module BMS cuts off the first relay 1 to stop charging and ends. If not, go back to step S1;

[0073] S5. The second judging unit judges whether the battery pack is overcharged. If so, the vehicle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com