Brake assembly and method for controlling brake assembly

A technology of brake components and brake discs, which is applied in the direction of brake components, brake transmission devices, and axially engaged brake parts, etc., and can solve problems such as damage to wheel brake parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

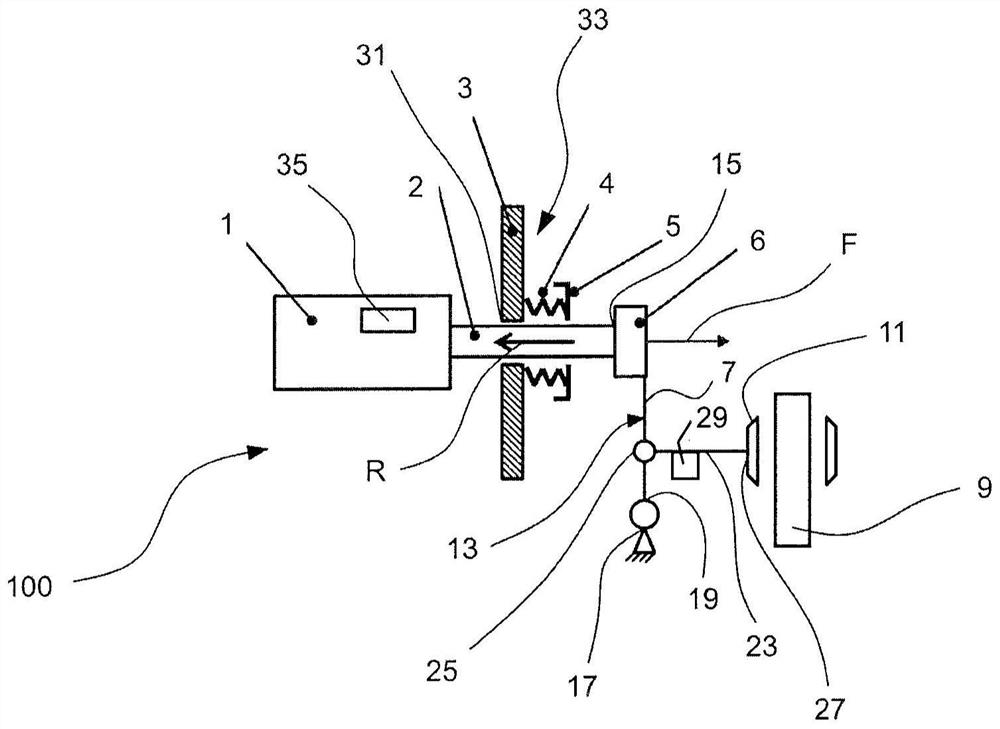

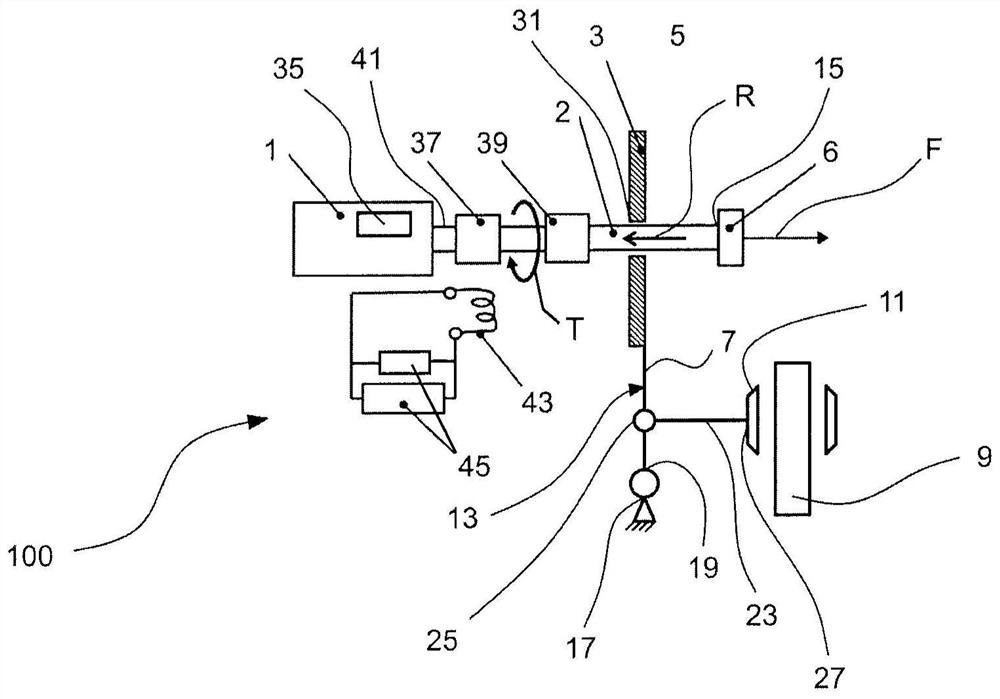

[0028] exist figure 1 , the active braking operation of the brake assembly is also shown. During a braking operation, the brake pads 11 are in frictional engagement with the brake disc 9 which is in rotational engagement with a wheel (not shown) of the vehicle. During a braking operation, a clamping force is exerted on the brake disc 9 by the brake pads 11 . Actuation of the brake pads 11 is achieved by means of a lever arrangement 13 . The lever arrangement 13 is coupled to the output shaft 2 which can be actuated by the actuator 1 . The lever arrangement 13 can be positively and / or force-fittingly coupled to the output shaft 2 via a coupling member 6 arranged at the distal end 15 of the output shaft 2 . The lever arrangement 13 comprises a pivot member 7 pivotably mounted with one end 19 of the rod 7 on a mount 17, usually fixedly arranged to the chassis of the vehicle (not shown) . At the other end 21 of the rod 7 , arranged diametrically opposite to the end 19 , the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com