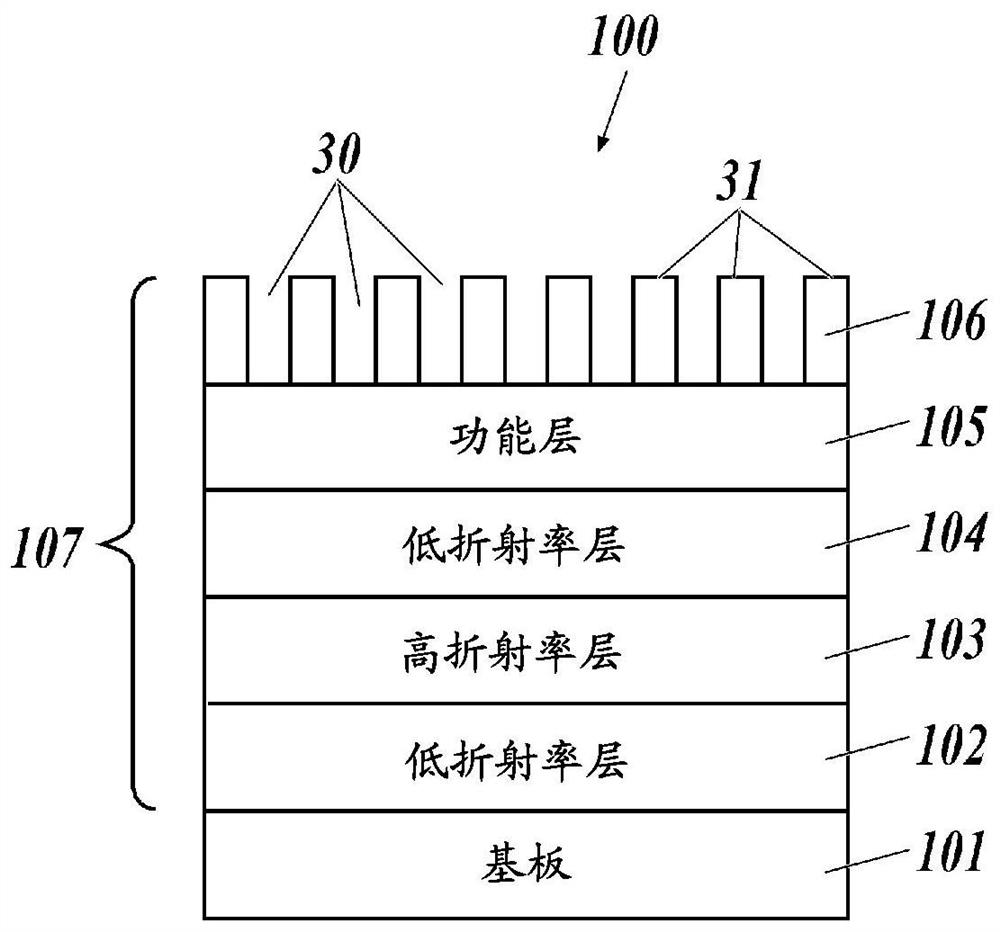

Dielectric multilayer film, method for producing same and optical member using same

A multi-layer film and dielectric technology, applied in optical components, optics, chemical instruments and methods, etc., can solve the problems of increased water contact angle, reduced salt water resistance, and change of light reflectivity, achieving low water contact angle, The effect of improving salt water resistance and scratch resistance, and improving hydrophilic function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0373] Specific examples of the dielectric multilayer film 100 according to this embodiment will be described below. It should be noted that a film forming apparatus (BES-1300) (manufactured by Synchron Co., Ltd.) was used for producing the following dielectric multilayer films.

[0374] "Fabrication of Dielectric Multilayer Films"

[0375] [Production of Dielectric Multilayer Film 1]

[0376] On a glass substrate TAFD5G (manufactured by HOYA Co., Ltd.: refractive index 1.835), SiO was laminated with a predetermined layer thickness by the IAD method using the following conditions. 2 (manufactured by Merck) for the low-refractive index layer, use OA600 (manufactured by Kanon Optron Corporation) Raw material: Ta 2 o 5 , TiO, Ti 2 o 5 mixture) until the layer numbers 1-3 in Table I. Second, as the use of TiO 2 The functional layer (layer number 4) and the uppermost layer (layer number 5) were vapor-deposited by the IAD method so that the sodium content became 5% by mass to...

Embodiment 2

[0477] "Fabrication of Dielectric Multilayer Films"

[0478] [Fabrication of Dielectric Multilayer Film 51 ]

[0479] On the glass substrate TAFD5G (manufactured by HOYA Co., Ltd.: refractive index 1.835), using the IAD method under the following conditions, SiO 2 (manufactured by Merck) for the low-refractive index layer, use OA600 (raw material manufactured by Kanon Optron Corporation: Ta 2 o 5 , TiO, Ti 2 o 5 mixture) until the layer numbers 1-3 in Table IV. Second, as the use of TiO 2 The functional layer (layer number 4) and the uppermost layer (layer number 5) were vapor-deposited by the IAD method so that the sodium content became 5% by mass to form the uppermost layer, and the layer number 5 recorded in Table IV was obtained. dielectric multilayer film.

[0480]

[0481] (chamber conditions)

[0482] Heating temperature 370°C

[0483] Start vacuum 1.33×10 -3 Pa

[0484] (Evaporation source of film-forming material)

[0485] electron gun

[0486]

[048...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap