Continuous feeding, stirring and friction additive manufacturing device and additive manufacturing method thereof

A technology of additive manufacturing, feeding and mixing, applied in the direction of manufacturing tools, additive processing, non-electric welding equipment, etc., can solve the problems of continuous feeding and feeding, easy generation of additive layer, interruption and restart, etc., to improve production efficiency , increase the connection width, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0050] The present invention will be described in detail below with reference to the accompanying drawings and examples.

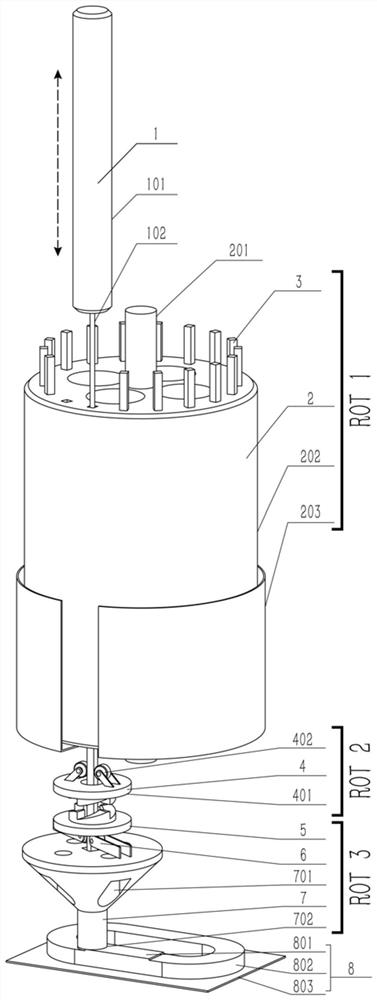

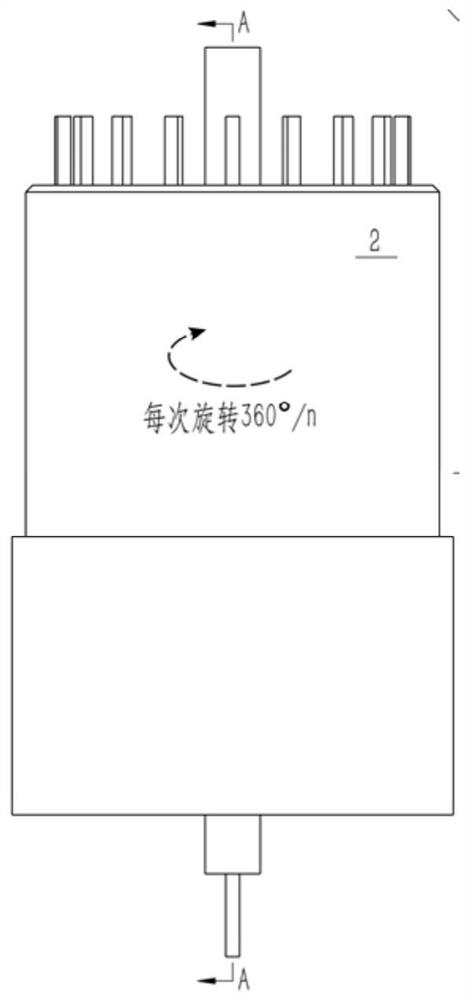

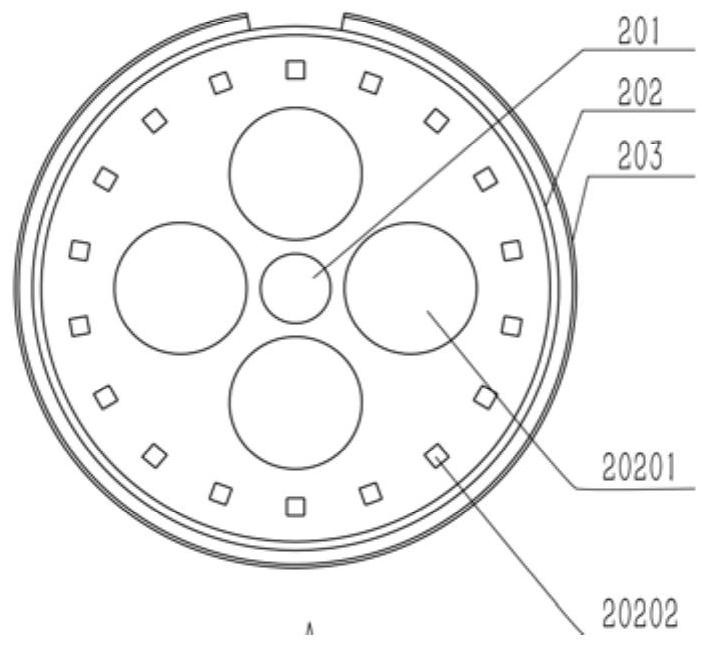

[0051] Such as Figure 1-10 As shown, a continuous feeding and feeding friction stir additive manufacturing device includes a hydraulic ejector mechanism 1, a disc feeding mechanism 2, an upper clutch module 4, a lower clutch module 5, and a constant speed feeding mechanism 6 arranged from top to bottom. , an additive mixing head 7 and an additive manufacturing component 8, a plurality of additive raw materials 3 with a square cross-section are evenly arranged in the disc feeding mechanism 2, and the lower clutch module 5 is fixed on the constant speed feeding mechanism 6, and the The constant-speed feeding mechanism 6 is fixed on the additive mixing head 7, the disc feeding mechanism 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com