Sponge cutting device with vertical wire knife

A sponge cutting and vertical knife technology, which is applied in metal processing and other directions, can solve the problems of high temperature of the cutter, material damage, large contact area between the cutter and the sponge, etc., to reduce roughness, reduce loss, and avoid high temperature damage sponge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

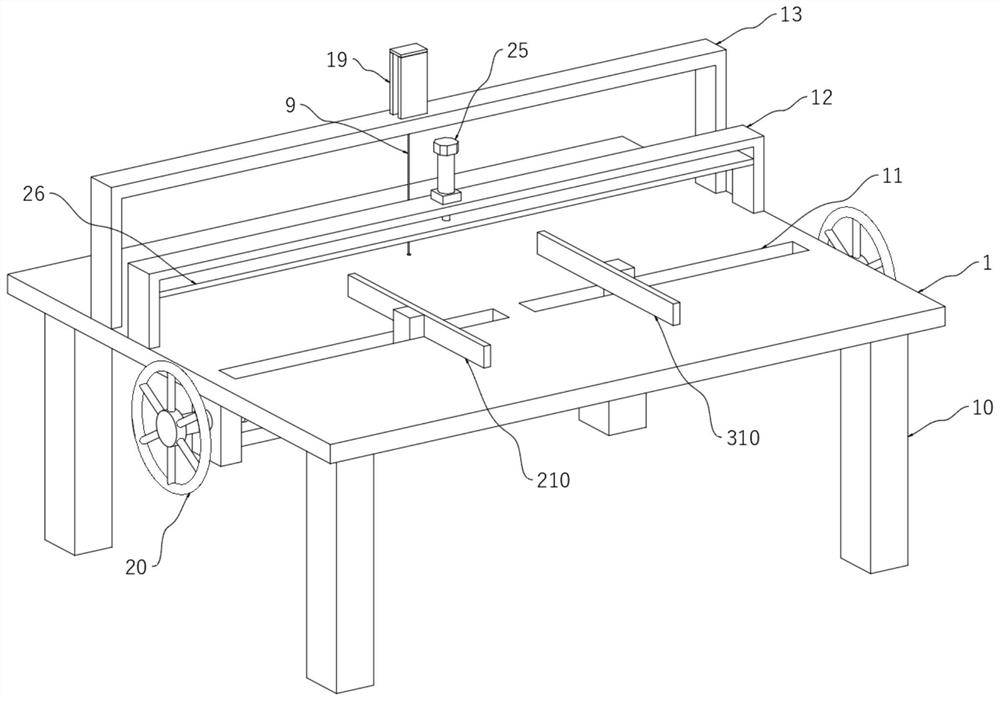

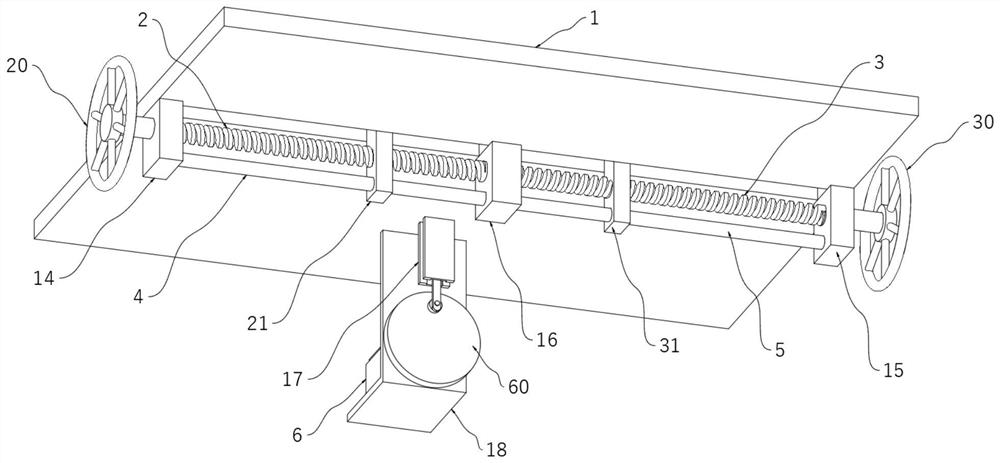

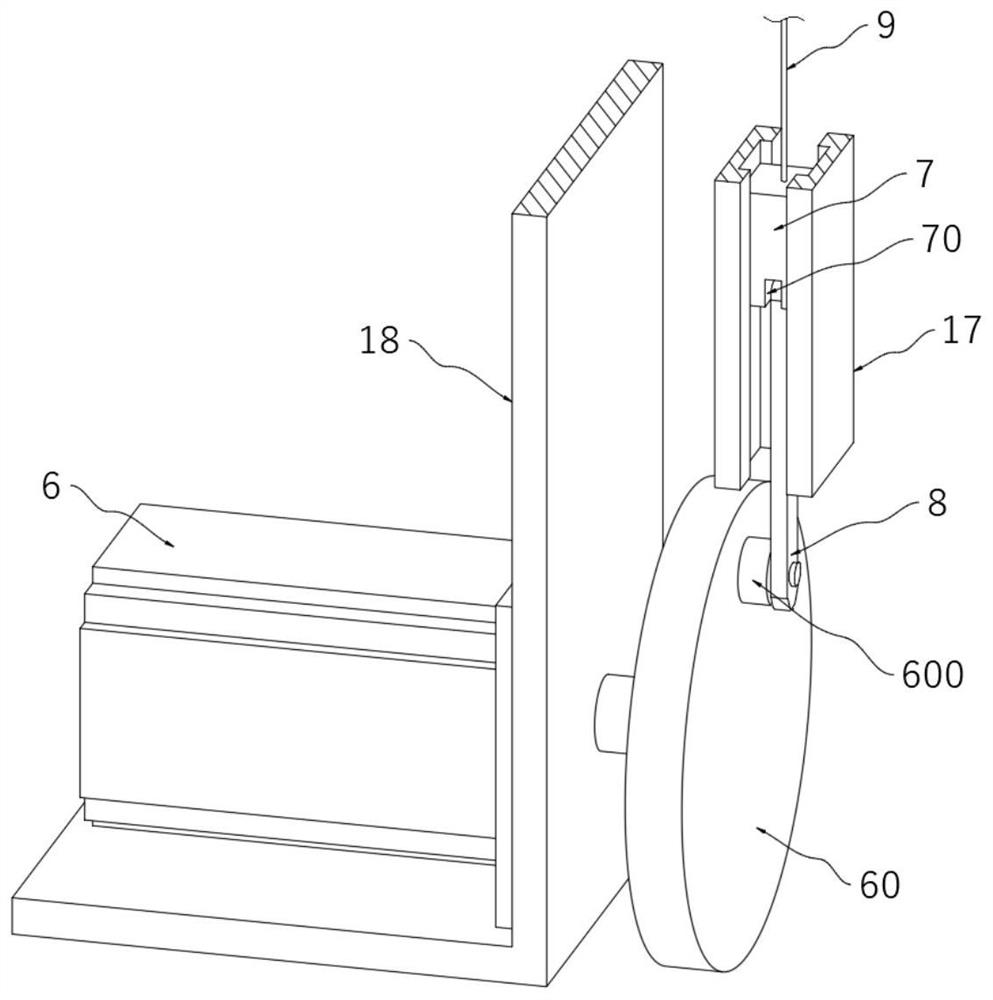

[0029]The sponge cutting device with thread cutter of the present invention comprises a workbench 1, the bottom of the workbench 1 and the positions near the four corners are all provided with supporting legs 10, the surface of the workbench 1 and the positions near the front side are provided with Symmetrically distributed bar-shaped chute 11, the edges on both sides of the bottom of the workbench 1 and near the front side are provided with symmetrically distributed first fixed projections 14 and second fixed projections 15, the bottom of the workbench 1 is located at the first The position between a fixed projection 14 and the second fixed projection 15 is provided with the third fixed projection 16, and the first screw rod 2 is connected with the rotation between the first fixed projection 14 and the third fixed projection 16. The outer wall of the screw 2 is threaded with a first moving block 21, the position of the first moving block 21 is adjusted by the first screw 2, an...

Embodiment 2

[0031] The sponge cutting device with thread cutter of the present invention comprises a workbench 1, the bottom of the workbench 1 and the positions near the four corners are all provided with supporting legs 10, the surface of the workbench 1 and the positions near the front side are provided with Symmetrically distributed bar-shaped chute 11, the edges on both sides of the bottom of the workbench 1 and near the front side are provided with symmetrically distributed first fixed projections 14 and second fixed projections 15, the bottom of the workbench 1 is located at the first The position between a fixed projection 14 and the second fixed projection 15 is provided with the third fixed projection 16, and the first screw rod 2 is connected with the rotation between the first fixed projection 14 and the third fixed projection 16. The outer wall of the screw 2 is threaded with a first moving block 21, the position of the first moving block 21 is adjusted by the first screw 2, a...

Embodiment 3

[0037] The sponge cutting device with thread cutter of the present invention comprises a workbench 1, the bottom of the workbench 1 and the positions near the four corners are all provided with supporting legs 10, the surface of the workbench 1 and the positions near the front side are provided with Symmetrically distributed bar-shaped chute 11, the edges on both sides of the bottom of the workbench 1 and near the front side are provided with symmetrically distributed first fixed projections 14 and second fixed projections 15, the bottom of the workbench 1 is located at the first The position between a fixed projection 14 and the second fixed projection 15 is provided with the third fixed projection 16, and the first screw rod 2 is connected with the rotation between the first fixed projection 14 and the third fixed projection 16. The outer wall of the screw 2 is threaded with a first moving block 21, the position of the first moving block 21 is adjusted by the first screw 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com