A kind of silage block wrapping film packing method

A technology of silage and material blocks, which is applied in the field of silage material wrapping and packaging, can solve the problems of low compression density of cylindrical material blocks, failure to output cuboid material blocks, and fermentation failure, etc., to achieve undetermined and reliable operation of equipment, The effect of continuous film wrapping and high compression density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The implementation of the present invention will be clearly and completely described below with reference to the accompanying drawings.

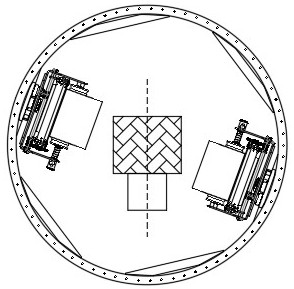

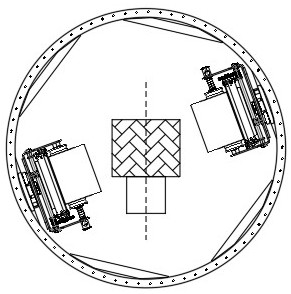

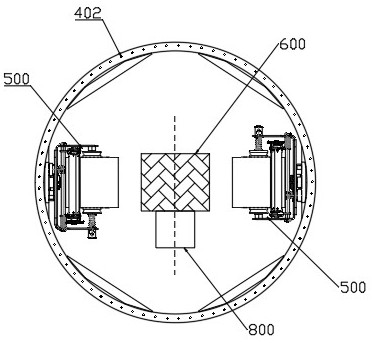

[0034] like Figure 1-4As shown in the figure, a set of integrated equipment for compression molding, film wrapping and packaging for straw silage includes a compression device 200, a shape-preserving discharge device 300, a film wrapping device 400, and a rotating mobile platform 800 in turn. The device 100, the compression device includes a compression chamber 201 and a first hydraulic cylinder 202, the shape retention and discharge device includes a shape retention cavity 301, the compression cavity 201 and the shape retention cavity 301 are both cuboid cylindrical structures and communicate with each other ;like Image 6 and 8 As shown, the film wrapping device includes a reel 402 that can be rotated in both forward and reverse directions. A film frame 500 is installed at each end of the inner diameter of the reel, and a film ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com