Cable detection equipment

A testing equipment and cable technology, applied in the field of cable testing equipment, can solve the problems of low testing efficiency, poor versatility of cable testing equipment, high labor cost, improve testing efficiency, realize fully automated testing and data control, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

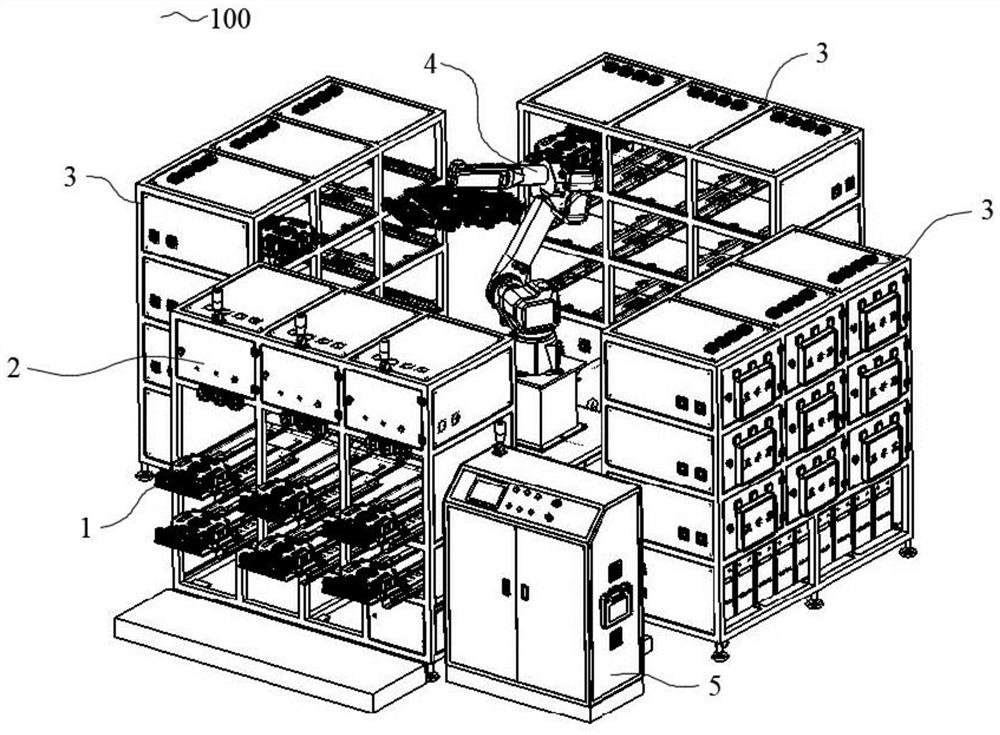

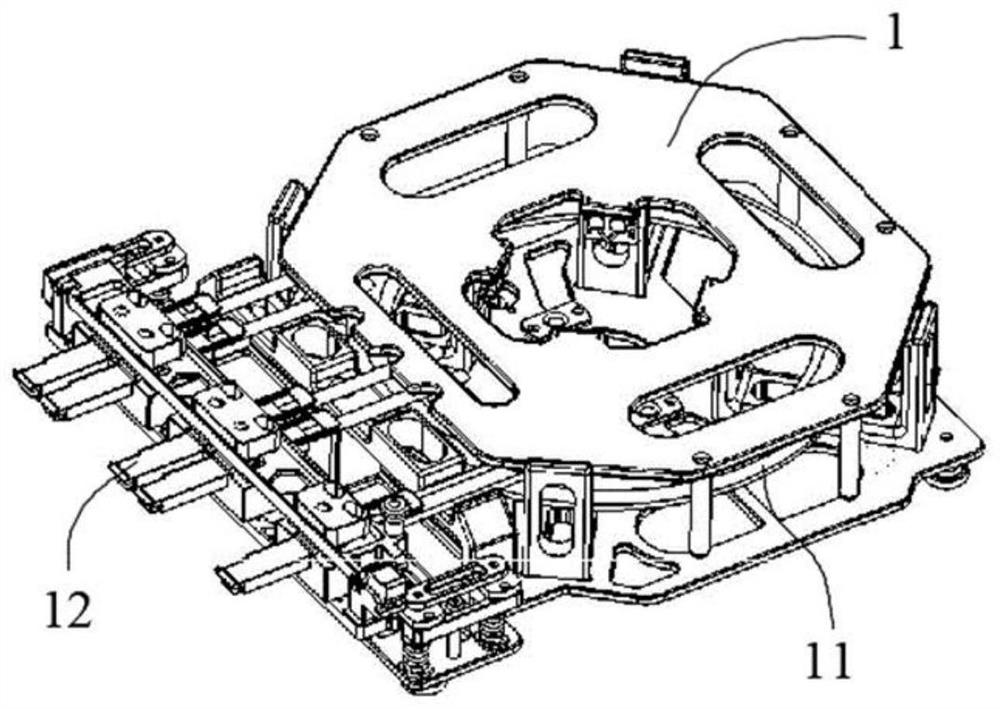

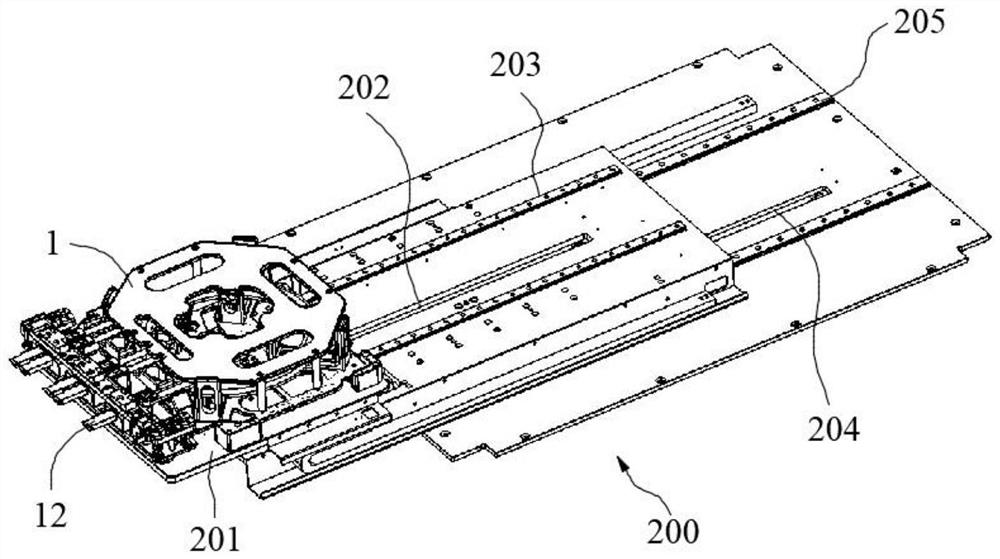

[0039] Such as figure 1 As shown, this embodiment provides a cable detection device, which includes: a carrier 1, an operating table 2, a detection device, a manipulator 4, and a controller 5. During specific use, the staff can place the device to be tested The carrier 1 of the cable is placed on the operating table 2, and then the controller 5 can set the program, and the carrier 1 on which the cable to be tested is placed is moved to the detection device by controlling the manipulator 4, and the detection device tests the cable to be tested. With different transmission characteristics, various testing processes of the cable 11 are completed. After the detection device completes the test, the detection device collects the test data, and the manipulator 4 returns the carrier 1 with the tested cable to the operating table 2, and the staff The work of recovering the carrier 1 of the tested cable is completed at the operating table 2, and the test work of the cable 11 is complete...

Embodiment 2

[0055] This embodiment provides a cable detection device, which is different from Embodiment 1 in that: the cable detection device in this embodiment includes a detection device, and the detection device includes a detection mechanism 3, and the detection mechanism 3 is arranged in parallel with the console 2 , the manipulator 4 is arranged in the middle position between the detection mechanism 3 and the operating platform 2 .

[0056] Preferably, the above-mentioned detection mechanism 3 includes a plurality of test stations 300, and the plurality of test stations 300 include one or more test units 304 and transmission units. The detection mechanism 3 in this embodiment includes nine test stations 300 as For example, each of the nine test stations 300 includes a test unit 304 and a transmission unit, and each test unit 304 is configured to detect a transmission characteristic of a cable 11 , and each transmission characteristic is different from each other.

[0057] Further, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com